Troubleshooting Distorted Protein Bands in Gel Electrophoresis: A Scientist's Guide to Diagnosis and Resolution

This article provides a comprehensive guide for researchers, scientists, and drug development professionals facing the common yet frustrating issue of distorted protein bands in SDS-PAGE.

Troubleshooting Distorted Protein Bands in Gel Electrophoresis: A Scientist's Guide to Diagnosis and Resolution

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals facing the common yet frustrating issue of distorted protein bands in SDS-PAGE. Covering the foundational principles of protein migration to advanced troubleshooting methodologies, the content details how to diagnose problems such as 'smiling' bands, smearing, and poor resolution. It offers systematic, step-by-step protocols for optimization, validates solutions through comparative analysis, and delivers actionable strategies to achieve publication-quality, reproducible results in biomedical research and development.

Understanding Protein Band Distortion: The Science Behind Your SDS-PAGE Results

Troubleshooting Guides

Why Are My Bands "Smiling" or "Frowning"?

Band smiling and frowning refer to patterns where bands in the middle of the gel migrate faster or slower than those on the edges, creating a curved appearance. This is almost always due to uneven heat distribution across the gel during the run [1].

- "Smiling" Bands: Curve upward, caused by faster migration in the center of the gel.

- "Frowning" Bands: Curve downward, caused by faster migration on the edges of the gel.

The table below outlines the common causes and solutions for this issue.

| Cause | Solution |

|---|---|

| Uneven Heat Dissipation (Joule heating) [1] | Run the gel at a lower voltage [1] or use a power supply with a constant current mode [1]. |

| Incorrect Buffer Concentration [1] | Use fresh buffer at the correct concentration [1]. |

| High Salt Concentration in Samples [1] | Desalt samples or dilute them to reduce salt concentration before loading [1]. |

| Overloaded Wells [1] | Load a smaller volume or more diluted sample [1]. |

| Improper Gel Tank Setup [1] | Ensure the gel is properly aligned, electrodes are straight, and buffer levels are even across the tank [1]. |

Why Are My Bands Smeared or Fuzzy?

Smeared bands appear as a continuous, blurry streak down the lane instead of sharp, distinct lines. This indicates a heterogeneous population of protein sizes, often due to degradation or improper denaturation [2] [1].

| Cause | Solution |

|---|---|

| Sample Degradation [1] | Keep samples on ice; use fresh protease inhibitors; avoid repeated freeze-thaw cycles [3]. |

| Improper Sample Denaturation [4] [5] | Ensure samples are heated at 95-98°C for 5 minutes with sufficient SDS and reducing agent (DTT or BME) [4]. After boiling, place samples immediately on ice to prevent re-folding [4]. |

| Protein Aggregation [6] | Ensure proper homogenization and sonication; for hydrophobic proteins, consider adding 4-8M urea to the lysis buffer [6]. |

| Gel Overheating [1] [5] | Run the gel at a lower voltage or perform electrophoresis in a cold room or using a cooling apparatus [1] [4]. |

| Incorrect Gel Percentage [1] | Use a gel with a pore size (percentage) appropriate for your target protein's size [1]. |

| Sample Overloading [2] [7] | Load less protein per well; a common starting point is 10-20 µg of total protein [7] [6]. |

Why Is My Band Resolution Poor?

Poor resolution means bands are too close together, blur into one another, or are not distinct, making it difficult to distinguish proteins of similar molecular weights [2].

| Cause | Solution |

|---|---|

| Suboptimal Gel Concentration [2] [1] | This is the most critical factor. Use higher % gels for smaller proteins and lower % gels for larger proteins [4]. |

| Incomplete Gel Polymerization [4] | Ensure all gel components (especially TEMED) are fresh and added in correct concentrations; allow enough time for complete polymerization [4]. |

| Incorrect Run Time [1] | Run the gel longer for better separation, but avoid excessive run times that cause band diffusion [1]. |

| Voltage Too High [1] | A high voltage can reduce separation efficiency. Run at a lower voltage for a longer duration [1] [4]. |

| Overloading the Wells [1] | Load a smaller amount of sample to prevent bands from becoming thick and merging [1]. |

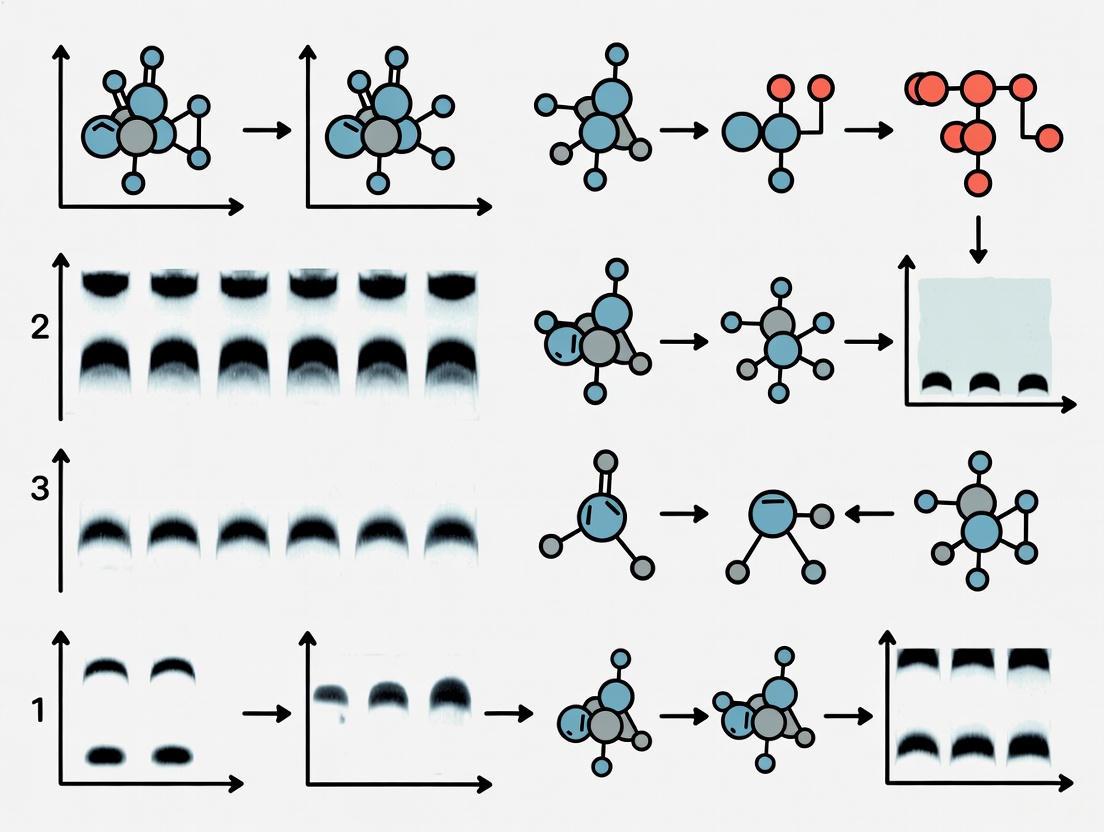

This workflow summarizes the systematic approach to diagnosing and resolving common protein band distortions.

Frequently Asked Questions (FAQs)

What is the single most important factor for improving band resolution?

The gel concentration is the most important factor. Selecting a gel with a pore size optimized for the molecular weight range of your target proteins is critical for achieving sharp, well-resolved bands [1].

My gel run failed completely with no bands visible. What should I check first?

The first step is to check your protein ladder or marker. If the ladder is not visible, the problem lies with the electrophoresis setup (e.g., power supply, buffer, or connections). If the ladder is visible but your sample bands are not, the problem is likely with the sample itself, such as degradation or insufficient concentration [1].

How can I prevent smiling bands?

To prevent smiling bands, reduce the voltage during the run to minimize Joule heating. Using a power supply with a constant current mode can also help maintain a more uniform temperature across the gel [1].

Why do my proteins form smears instead of sharp bands?

Smearing is most often caused by sample degradation or incomplete denaturation. To fix this, always handle samples on ice with protease inhibitors and ensure they are properly boiled in a buffer containing SDS and a reducing agent like DTT to linearize the proteins fully [1] [4] [5].

Research Reagent Solutions

The following table lists essential reagents and materials used in SDS-PAGE to achieve optimal results and troubleshoot common band distortions.

| Reagent/Material | Function in SDS-PAGE |

|---|---|

| SDS (Sodium Dodecyl Sulfate) | A detergent that denatures proteins and confers a uniform negative charge, allowing separation based primarily on molecular weight [4]. |

| Acrylamide/Bis-acrylamide | Forms the cross-linked polyacrylamide gel matrix that acts as a molecular sieve for separating proteins [4]. |

| TEMED & Ammonium Persulfate (APS) | Catalyzes the polymerization reaction of acrylamide to form the gel [4]. |

| DTT or β-mercaptoethanol | Reducing agents that break disulfide bonds within and between proteins, ensuring complete denaturation and unfolding [7] [4]. |

| Glycerol | A component of loading dye that increases sample density, allowing it to sink to the bottom of the well during loading [6]. |

| Coomassie Blue/Silver Stain | Dyes used for visualizing protein bands on the gel after electrophoresis [8]. |

| Tris-Glycine or Bis-Tris Buffers | Common buffer systems that maintain a stable pH during electrophoresis, which is critical for consistent protein migration [4]. |

In protein gel electrophoresis, the predictable separation of proteins by molecular weight can be compromised by physical artifacts, chief among them being distortions caused by Joule heating and electric field irregularities. A fundamental understanding of these principles is essential for any researcher aiming to produce high-quality, reproducible data. This technical support guide outlines the core physics governing protein migration and provides a systematic, troubleshooting-focused approach to diagnosing and resolving the most common issues of band distortion, framed within the context of a broader thesis on gel research.

Core Physics and Troubleshooting Guide

The following section directly connects the physical principles of electrophoresis to observable problems in the lab, providing a diagnostic framework and proven solutions.

Troubleshooting Distorted Protein Bands

Summary of Common Issues and Solutions

| Problem Observed | Primary Physical Cause | Underlying Experimental Error | Recommended Solution |

|---|---|---|---|

| 'Smiling' or 'Frowning' Bands (curved bands) [9] [1] | Joule Heating: Uneven heat distribution across the gel causes differential migration rates (faster in warmer center) [1]. | Voltage set too high; inadequate cooling; uneven buffer levels [7] [9]. | Run gel at lower voltage for longer time; use a cooling system or cold room; ensure buffer levels are even and cover the gel completely [7] [9] [1]. |

| Smeared Bands (diffuse, fuzzy bands) [9] | Improper Denaturation or Sample Degradation: Proteins are not uniformly charged or are partially cleaved, leading to a continuum of sizes and charges [7] [10]. | Old or insufficient reducing agent; sample degraded by proteases; voltage too high [7] [10] [9]. | Prepare fresh sample with fresh reducing agent (DTT/BME); heat denature immediately after preparation; run gel at recommended voltage [7] [10]. |

| Poor Band Resolution (bands too close, not distinct) [9] [1] | Incorrect Gel Porosity or Run Time: The gel matrix does not provide optimal sieving for the target protein size range [9]. | Gel percentage inappropriate for protein size; gel run too short or too long [9]. | Use a higher percentage gel for low MW proteins and lower percentage for high MW proteins; optimize run time so dye front nears bottom but does not run off [9]. |

| Vertical Streaking [7] [11] | Protein Aggregation/Precipitation: Insoluble protein complexes form in the well, resisting entry into the gel matrix. | Sample overload; high salt concentration; presence of insoluble material [7] [11]. | Reduce amount of protein loaded; desalt sample or dilute in lower salt buffer; centrifuge sample to remove insolubles before loading [7] [11]. |

| Horizontal Band Distortion ('Barbell' Bands) [7] | Sample Diffusion: Large sample volume leads to diffusion to sides of well before stacking. | Loading too large a sample volume [7]. | Concentrate the protein sample and load a smaller volume [7]. |

Diagnostic and Remedial Workflow

The following diagram outlines a logical decision-making process for troubleshooting distorted bands, based on their visual characteristics.

Essential Research Reagent Solutions

The quality and preparation of reagents are foundational to successful electrophoresis. The following table details key materials and their critical functions.

Essential Materials for SDS-PAGE Troubleshooting

| Reagent/Material | Function & Importance in Troubleshooting |

|---|---|

| Fresh Reducing Agents (DTT, β-mercaptoethanol) [7] [10] | Breaks disulfide bonds for complete protein unfolding. Critical for preventing smearing caused by re-oxidation or incomplete denaturation during the run [7]. |

| High-Purity SDS [7] | Binds to proteins in a constant mass ratio, imparting a uniform negative charge. Insufficient SDS leads to aberrant migration and smearing [7]. |

| Appropriate Gel Matrix (Bis-Tris, Tris-Glycine) [7] [9] | Provides the sieving matrix for separation. The percentage and buffer system must be matched to the target protein's molecular weight to ensure proper resolution [9]. |

| Fresh Electrophoresis Buffer [9] [1] | Maintains stable pH and provides ions to carry current. Old, contaminated, or incorrect buffer concentration alters resistance, leading to heating issues and distorted bands [1]. |

| Protease Inhibitors [10] | Prevents protein degradation by proteases that can remain active in sample buffer at room temperature, a common cause of extra or smeared bands [10]. |

Frequently Asked Questions (FAQs)

1. My protein bands curve upwards ('smile') at the edges. What is the physical cause and how can I fix it?

The "smiling" effect is a direct result of Joule heating [1]. As electrical current passes through the gel, resistance generates heat. If the center of the gel becomes significantly warmer than the edges, molecules migrate faster in the center, creating a curved band. To resolve this, reduce the voltage to decrease heat generation and/or improve heat dissipation by running the gel in a cold room, using a dedicated cooling unit, or ensuring the buffer chamber is fully filled to act as a heat sink [7] [9] [1].

2. I see smeared bands instead of sharp ones across all lanes. What are the most likely culprits?

Widespread smearing typically points to issues with sample integrity or denaturation [7] [9]. First, ensure you are using fresh reducing agents (DTT or β-mercaptoethanol) to fully break disulfide bonds, and that you heat-denature your samples immediately after preparation to inactivate proteases [7] [10]. Second, check that you are not overloading the gel with too much protein. Finally, verify that you are not running the gel at an excessively high voltage, which can cause localized overheating and protein denaturation during the run [9].

3. My samples diffused out of the wells before I even started the gel. Why did this happen?

This occurs when there is a significant delay between loading the samples and applying the electric current [11]. Without the electric field to pull them into the gel matrix, the dense protein samples will passively diffuse out of the wells. The solution is to minimize the time between loading and starting the electrophoresis run. Load your samples efficiently and apply the voltage immediately afterward [11].

4. How does high salt concentration in my sample interfere with electrophoresis?

High salt increases the local conductivity in and around the sample well [7] [1]. This creates a region where the electric field is stronger, leading to localized Joule heating and distorted band shapes as the sample enters the gel. It can also disrupt the stacking process, leading to poor resolution. To avoid this, desalt your samples using dialysis, size-exclusion chromatography, or precipitation before preparing them for SDS-PAGE [7].

Within the molecular biology laboratory, gel electrophoresis serves as a cornerstone technique for protein analysis. The quality of the data, however, is entirely dependent on the integrity of the bands revealed post-electrophoresis. Distorted, smeared, or poorly resolved bands are not mere inconveniences; they are symptoms of underlying issues, frequently rooted in the preparation and handling of critical reagents. This technical guide, framed within a broader thesis on troubleshooting, examines the specific roles of acrylamide, buffers, and SDS in dictating band morphology. By understanding how these reagents influence experimental outcomes, researchers and drug development professionals can systematically diagnose problems, implement corrective actions, and ensure the generation of reproducible, high-quality data.

The Scientist's Toolkit: Essential Reagents and Their Functions

Successful electrophoresis relies on a suite of carefully prepared reagents. The following table details key components, their primary functions, and the consequences of their misuse.

Table 1: Key Research Reagent Solutions for Gel Electrophoresis

| Reagent | Primary Function | Impact of Improper Use on Band Morphology |

|---|---|---|

| Acrylamide/Bis-acrylamide | Forms the porous gel matrix that sieves proteins based on size [4]. | Incorrect concentration causes poor resolution; incomplete polymerization leads to smearing and distorted bands [7] [4]. |

| SDS (Sodium Dodecyl Sulfate) | Denatures proteins and confers a uniform negative charge, allowing separation based solely on molecular weight [4]. | Insufficient SDS causes incomplete denaturation, leading to smearing, aggregation, and inaccurate molecular weight estimation [7] [12]. |

| Running Buffer | Carries the current and maintains a stable pH during the run [13]. | Overused or incorrect buffer concentrations distort the electric field, causing smiling/frowning bands and poor resolution [1] [4]. |

| TEMED & APS (Ammonium Persulfate) | Catalyze the polymerization of acrylamide to form the gel [14]. | Inadequate amounts cause slow or incomplete polymerization, resulting in a soft gel, poor well formation, and smeared bands [14]. |

| Sample Buffer (with Reducing Agents) | Denatures, reduces, and colors the protein sample for loading. | Old or insufficient reducing agent (DTT/β-mercaptoethanol) leads to re-oxidation, vertical streaking, and artifact bands [7] [14]. |

Troubleshooting Guides: Reagent-Specific Issues and Solutions

Acrylamide: The Sieving Matrix

The polyacrylamide gel is the physical medium for separation. Its precise composition is paramount.

Table 2: Troubleshooting Acrylamide-Related Issues

| Problem | Root Cause | Solution |

|---|---|---|

| Poor Band Resolution | Gel percentage is not optimized for the target protein size range [1] [4]. | Use a higher % gel for small proteins and a lower % gel for large proteins. For a broad size range, use a gradient gel [14]. |

| Smeared or Distorted Bands | Gel polymerization is incomplete or uneven [7] [4]. | Ensure TEMED and APS are fresh and added in correct concentrations. Degas the acrylamide solution to prevent air bubbles [14]. |

| Wavy Bands | Uneven polymerization from temperature variations or air bubbles trapped during casting [12]. | Pour gels in a stable temperature environment and degas solutions. Insert the comb straight and level [12]. |

Buffers: The Conductive Environment

Buffers are not merely conductive solutions; they are vital for maintaining the chemical environment necessary for consistent protein migration.

Table 3: Troubleshooting Buffer-Related Issues

| Problem | Root Cause | Solution |

|---|---|---|

| "Smiling" or "Frowning" Bands | Uneven heat distribution (Joule heating) across the gel, often due to high voltage or incorrect buffer concentration [1] [13]. | Run the gel at a lower voltage for a longer time. Use a constant current power supply and ensure buffer is fresh and at the correct level [1]. |

| Poor Band Resolution | Buffer is depleted, overused, or incorrectly prepared, altering pH and ion concentration [1] [13]. | Always prepare fresh running buffer before each run or as frequently as possible [4]. |

| Unusually Fast or Slow Migration | Running buffer is too diluted or too concentrated [13] [14]. | Check the buffer recipe and re-make it at the correct concentration [7]. |

SDS and Sample Preparation: The Key to Denaturation

The combination of SDS and proper sample preparation is what enables separation by molecular weight. Failures here are a common source of artifacts.

Table 4: Troubleshooting SDS and Sample Preparation Issues

| Problem | Root Cause | Solution |

|---|---|---|

| Vertical Streaking | Protein precipitation in the well due to high salt content, insufficient SDS, or inadequate denaturation [7] [12]. | Desalt samples, add more SDS to the sample buffer, and ensure samples are heated at 95-100°C for 3-5 minutes [7] [12]. |

| Smeared Bands | Sample degradation by proteases; or SDS not binding properly due to high salt [1] [10]. | Keep samples on ice, add protease inhibitors, and desalt samples. For hydrophobic proteins, add 4-8 M urea to the sample buffer [10] [14]. |

| Artifact Bands (e.g., ~67 kDa) | Presence of excess reducing agent (β-mercaptoethanol) in reduced samples [14]. | Add iodoacetamide to the equilibration buffer to alkylate the proteins and eliminate this artifact [14]. |

| Horizontal Band Spreading | Sample diffused out of the well before the power was applied [13] [14]. | Minimize the time between loading the last sample and starting the electrophoresis run [13]. |

Experimental Protocols for Diagnosis

Protocol 1: Verifying Sample Integrity and Denaturation

Purpose: To determine if band smearing or distortion is caused by sample degradation or improper denaturation [10] [4].

- Split Sample: Divide your protein sample into two aliquots.

- Immediate Denaturation: Add one aliquot to pre-prepared SDS sample buffer and heat immediately at 95-100°C for 5 minutes.

- Delayed Denaturation: Add the second aliquot to sample buffer but leave it at room temperature for 2-4 hours before heating.

- Analyze: Run both samples on an SDS-PAGE gel side-by-side.

- Interpretation: Increased smearing or additional bands in the "delayed" sample indicate protease degradation or other time-dependent sample integrity issues [10].

Protocol 2: Investigating Buffer and Electrical Field Issues

Purpose: To diagnose problems related to buffer condition or electrophoresis parameters [1] [7].

- Prepare Fresh Buffer: Discard the old running buffer and prepare a fresh batch with correct pH and concentration.

- Check Apparatus: Inspect the electrophoresis tank for damaged electrodes or leaks. Ensure the gel is properly seated and buffer levels are even.

- Optimize Run Conditions: If "smiling" or "frowning" occurs, reduce the run voltage by 25-50% and increase the run time [13] [14]. Consider running the gel in a cold room or using an apparatus with a cooling function [1] [4].

- Interpretation: Improved band morphology with fresh buffer and/or lower voltage confirms issues with buffer depletion or excessive Joule heating.

Frequently Asked Questions (FAQs)

Q1: My protein bands are "smiling" (curving upward at the edges). What is the most likely cause and how do I fix it? A: "Smiling" bands are predominantly caused by uneven heating across the gel, where the center becomes hotter than the edges [1] [13]. To resolve this, run the gel at a lower voltage to minimize Joule heating. Using a power supply with a constant current mode or ensuring your apparatus is in a cool environment can also help [1].

Q2: I see a heavy, fuzzy band at the dye front and poor separation. Is this a reagent issue? A: Yes. A heavy band at the dye front often indicates that the acrylamide percentage of your gel is too low for the size of your proteins, failing to provide adequate sieving [14]. For your next experiment, use a gel with a higher percentage of acrylamide to better resolve smaller proteins [4].

Q3: My gel shows vertical streaking down from the wells. What went wrong in my sample prep? A: Vertical streaking typically points to protein precipitation in the wells [12]. This is commonly caused by a high salt concentration in your sample or insufficient SDS to keep the proteins solubilized [7]. Desalting your sample or ensuring your sample buffer contains an adequate excess of SDS will usually correct this issue [14] [12].

Q4: Despite loading a known amount of protein, my bands are faint or absent. What should I check first? A: First, verify your electrophoresis setup was functional by checking if the protein ladder is visible. If the ladder is absent, the problem lies with the power supply, connections, or buffer [1]. If the ladder is visible, the issue is sample-specific. Re-check your sample preparation, ensure you are not using degraded protein, and confirm that your staining solutions are fresh and active [14].

Visual Guide: Troubleshooting Distorted Band Morphology

The following workflow diagram synthesizes the information in this guide into a logical diagnostic pathway.

This guide details how protein properties—their composition, size, and inherent charge—directly influence band appearance in SDS-PAGE, a cornerstone technique in molecular biology. Understanding these interactions is essential for accurate interpretation of results and effective troubleshooting of distorted or anomalous bands. The following sections provide a structured framework to diagnose and resolve common issues, ensuring data reliability.

Scientific Principles: How Protein Properties Affect Electrophoresis

In SDS-PAGE, the detergent Sodium Dodecyl Sulfate (SDS) plays a critical role by binding to proteins and unfolding them, effectively masking their native charge. This coats all proteins with a uniform negative charge, allowing separation by molecular weight rather than charge [15]. However, certain protein properties can complicate this process:

- Protein Composition: Hydrophobic proteins may bind more SDS, while post-translational modifications like phosphorylation and glycosylation can interfere with SDS binding, causing proteins to migrate at unexpected molecular weights [15].

- Protein Size: The polyacrylamide gel acts as a molecular sieve. The pore size, determined by the acrylamide concentration, dictates the migration speed of linearized proteins. Higher acrylamide percentages create smaller pores, ideal for resolving smaller proteins, while lower percentages with larger pores are better for separating larger proteins [15].

The discontinuous buffer system, utilizing stacking and resolving gels with different pH and acrylamide concentrations, is designed to focus all protein samples into a sharp line before they enter the resolving gel, ensuring tight, well-defined bands [15].

Troubleshooting Guide: Band Distortions and Solutions

The table below outlines common band distortions, their probable causes rooted in protein properties or experimental protocol, and recommended corrective actions.

| Observation | Probable Cause | Troubleshooting Action |

|---|---|---|

| Smeared Bands [16] | Gel run at excessively high voltage, causing overheating. | Run gel at 10-15 V/cm. Use lower voltage for longer time; run in cold room or with ice packs. |

| Bands at Unexpected Molecular Weight [15] | Altered SDS binding due to hydrophobicity or PTMs (e.g., glycosylation). | Consider composition; use deglycosylation enzymes or alternative methods for validation. |

| Poor Band Resolution (unclear/overlapping bands) [16] | Gel run time too short; acrylamide concentration inappropriate for target protein size. | Run gel until dye front nears bottom; optimize acrylamide percentage for protein size range. |

| 'Smiling' Bands (curved bands) [16] | Excessive heat generation during electrophoresis, causing uneven gel expansion. | Run gel at lower voltage for longer time; use a cold room or cooling packs in the apparatus. |

| 'Edge Effect' (distorted peripheral lanes) [16] | Empty wells on the outer edges of the gel. | Load all peripheral wells with sample, ladder, or control protein; avoid leaving wells empty. |

| Sample Diffuses Out of Well [16] | Lag between sample loading and starting electrophoresis. | Start electrophoresis immediately after loading the last sample; minimize loading time. |

Essential Reagents and Their Roles in SDS-PAGE

A successful SDS-PAGE experiment relies on a specific set of reagents, each with a critical function as outlined below.

| Reagent | Function |

|---|---|

| SDS (Sodium Dodecyl Sulfate) [15] | Denatures proteins and confers a uniform negative charge. |

| Acrylamide [15] | Forms the cross-linked gel matrix that separates proteins by size. |

| TEMED & Ammonium Persulfate (APS) [15] | Catalyzes the polymerization of acrylamide to form the gel. |

| Tris-HCl Buffer [15] | Maintains stable pH in both stacking and resolving gels. |

| Glycine [15] | Key ion in discontinuous buffer system; enables stacking at gel interface. |

| Beta-Mercaptoethanol (BME) [15] | Reducing agent that breaks disulfide bonds for complete denaturation. |

| Glycerol [15] | Adds density to sample, ensuring it sinks to bottom of loading well. |

| Bromophenol Blue [15] | Tracking dye that allows visual monitoring of electrophoresis progress. |

A standard SDS-PAGE protocol involves several key stages [15]:

- Sample Preparation: Mix protein samples with Laemmli buffer (containing SDS, glycerol, BME, and Bromophenol Blue). Heat denature (95°C for 5 minutes) to fully linearize proteins.

- Gel Preparation: Cast a discontinuous gel with a stacking gel (lower acrylamide, pH ~6.8) on top of a resolving gel (higher acrylamide, pH ~8.8).

- Loading and Running:

- Load prepared samples and molecular weight ladder into wells. Do not leave outer wells empty to prevent the "edge effect" [16].

- Fill the tank with running buffer (containing Tris, glycine, and SDS, pH ~8.3).

- Connect to power supply and run at constant voltage (e.g., 150V for a mini-gel) until the dye front reaches the bottom of the gel. Adjust voltage to prevent overheating and smearing [16].

- Post-Run Analysis: Disassemble apparatus and process gel for staining (e.g., Coomassie Blue) or western blotting.

The diagram below illustrates the core workflow and the critical role of key reagents in preparing proteins for separation by size.

Frequently Asked Questions (FAQs)

Q1: Why might my protein run at a different molecular weight than predicted?

While size is the primary factor, protein composition can alter SDS binding. Hydrophobic proteins may bind more SDS, while post-translational modifications like glycosylation or phosphorylation can cause less SDS to bind. This changes the protein's charge-to-mass ratio and can lead to anomalous migration [15].

Q2: How do I choose the right acrylamide percentage for my gel?

The optimal acrylamide percentage depends on the molecular weight of your target protein. Use a lower percentage (e.g., 8%) for resolving high molecular weight proteins, and a higher percentage (e.g., 12-15%) for better separation of low molecular weight proteins [15].

Q3: What is the maximum volume I can load into a gel well?

The maximum volume depends on the well format and gel thickness. For example, a standard 10-well mini gel with 1.0 mm thickness has a recommended loading volume of 25 µL, while a 1.5 mm thick gel of the same format can hold 37 µL. Always refer to manufacturer specifications for your specific gel system [17].

Q4: My bands are fuzzy or smeared. What is the most common cause?

Running the gel at too high a voltage is a frequent cause of smeared bands. The excess heat generated can denature proteins unevenly and distort band shape. Troubleshoot by running the gel at a lower voltage for a longer duration [16].

Q5: What causes "smiling" or "frowning" bands, and how can I fix it?

"Smiling" bands (curved upward) are typically caused by uneven heating across the gel, often from running at too high a voltage. This can be mitigated by running the gel at a lower voltage, in a cold room, or by using the apparatus's cooling system [16].

Optimal SDS-PAGE Protocol: A Step-by-Step Method for Flawless Gel Execution

In the critical analysis of protein gel electrophoresis, distorted bands are not merely an aesthetic issue; they are a primary indicator of underlying flaws in the gel casting process. These distortions can lead to misinterpretation of data, failed experiments, and costly delays in research and development pipelines. Achieving perfection in gel casting—specifically, consistent polymerization and the formation of perfectly defined wells—is a foundational skill for any scientist relying on SDS-PAGE. This guide provides a targeted, troubleshooting-focused approach to identifying and resolving the most common gel casting issues that lead to distorted protein bands, ensuring your results are reliable and reproducible.

Troubleshooting Guides & FAQs

Why are my protein bands not parallel?

The Problem: Protein bands that are not parallel and evenly spaced indicate an issue with the initial conditions of the electrophoretic run. This often points to an uneven polymerization of the gel, leading to a slanted interface between the stacking and resolving gels. When this interface is not uniform, samples in different lanes start their separation from slightly different baselines, causing them to migrate at different rates and resulting in non-parallel, "smiling" or "frowning" bands [18] [19].

The Solutions:

- Verify Polymerization: Before loading your samples, always ensure your gel has fully polymerized. If issues persist, consider a slight increase (e.g., 1%) in the acrylamide concentration for the resolving gel [18].

- Create a Level Interface: After pouring the resolving gel, top it carefully with a layer of isopropanol or water. This creates a uniform, level surface that prevents oxygen (an inhibitor of polymerization) from creating an uneven gel top. Once polymerized, pour off the isopropanol, rinse with water, and then pour the stacking gel [18] [20].

- Ensure a Linear Gel Interface: The practice above ensures the stacking-resolving gel interface is straight across the entire gel. This is critical for ensuring all samples in every lane begin separation at the exact same baseline, promoting uniform band separation [18].

Why is my sample leaking out of the wells during or after loading?

The Problem: Samples leaking from wells result in distorted, missing, or uneven protein bands. This can also cause cross-contamination between adjacent lanes, leading to erroneous results. Leakage is typically caused by physical damage to the wells during comb removal or sample loading, or by using a gel that is too old and has deteriorated [18].

The Solutions:

- Gentle Comb Removal: Always remove the comb slowly and steadily, pulling straight up. For best results, remove the comb after the gel cassette has been placed in the running chamber and the chamber has been filled with running buffer. The buffer provides hydraulic support that helps prevent the wells from collapsing [18] [2].

- Pre-Loading Well Inspection: Prior to loading your samples, fill the wells with a small amount of loading dye to check for any visible leaks or damage [18].

- Careful Sample Loading: When loading samples, be careful not to touch the bottom or sides of the wells with your pipette tip, as this can puncture or damage them [18] [2].

Why are my bands not separating properly, appearing smeared or blurry?

The Problem: Poorly separated or smeared bands fail to resolve into distinct, sharp bands, making analysis impossible. This can be caused by an incorrect acrylamide concentration for your target protein size, improper sample preparation, or overloading of the protein sample [18] [4].

The Solutions:

- Optimize Gel Percentage: The pore size of the gel matrix is determined by the acrylamide percentage. For high molecular weight proteins that migrate slowly, use a lower percentage gel (e.g., 8%) with larger pores. For low molecular weight proteins, use a higher percentage gel (e.g., 12%) with smaller pores to achieve proper separation [18] [4].

- Ensure Complete Sample Denaturation: Proteins must be fully denatured to migrate strictly by size. Increase the boiling time of your samples (typically 5 minutes at 98°C) and then place them immediately on ice to prevent renaturation. Verify that your sample buffer contains sufficient SDS and reducing agent (DTT or β-mercaptoethanol) [4].

- Load the Appropriate Amount of Protein: Overloading a well causes proteins to aggregate and prevents clean separation. Use the minimum amount of protein required for detection. For crude samples, 40–60 µg is typical for Coomassie staining, while less is needed for more sensitive silver staining or western blotting [10] [4].

What causes smeared bands across the entire lane?

The Problem: A smeared appearance, where bands are diffuse and fuzzy across the lane, often indicates protein degradation or aggregation during sample preparation [10].

The Solutions:

- Inhibit Protease Activity: Proteases in your sample can digest proteins while they are in sample buffer at room temperature. Always heat your samples immediately after adding them to the sample buffer to inactivate proteases. As a test, compare a sample heated immediately to one left at room temperature for 2-4 hours before heating [10].

- Avoid Cleaving Asp-Pro Bonds: Heating proteins at 95-100°C for too long can cleave acid-labile Asp-Pro bonds. If this is suspected, try heating at 75°C for 5 minutes, which is often sufficient for denaturation without causing this specific cleavage [10].

- Remove Insoluble Material: After heating your sample, centrifuge it briefly (e.g., 2 minutes at 17,000 x g) to pellet any insoluble debris. Loading this material will cause streaking in the gel [10].

Experimental Protocols

Standard Protocol for Hand-Casting a Discontinuous SDS-PAGE Gel

This protocol is fundamental for achieving consistent, high-quality gels. Deviations can introduce the very issues detailed in the troubleshooting guide above.

Research Reagent Solutions

| Reagent | Function |

|---|---|

| 40% Acrylamide/Bis Solution | Forms the polyacrylamide gel matrix; the pore size is determined by the concentration. |

| 1.5 M Tris-HCl, pH 8.8 | Buffer for the resolving gel; creates the correct pH environment for separation. |

| 0.5 M Tris-HCl, pH 6.8 | Buffer for the stacking gel; the different pH is key for the discontinuous buffer system. |

| 10% Sodium Dodecyl Sulfate (SDS) | Denaturing agent that confers a uniform negative charge to the proteins. |

| 10% Ammonium Persulfate (APS) | Initiator of the polymerization reaction; must be fresh for efficient polymerization. |

| TEMED | Catalyst that accelerates the polymerization reaction by generating free radicals from APS. |

| Isopropanol | Used to layer on top of the resolving gel to exclude oxygen and create a flat surface. |

Step-by-Step Methodology [20]:

- Setup: Thoroughly clean the glass plates with 70% ethanol. Assemble the gel casting module according to the manufacturer's instructions, ensuring a tight seal to prevent leaks.

- Prepare Resolving Gel: Mix the reagents for your desired resolving gel percentage (see table below) in a Falcon tube. Add TEMED last, as polymerization begins immediately. Mix quickly but thoroughly.

- Cast Resolving Gel: Using a serological pipette, transfer the resolving gel solution between the glass plates until it reaches the desired height (typically ~2/3 of the cassette). Immediately layer isopropanol on top to create a flat, oxygen-free surface.

- Polymerize: Allow the gel to polymerize for 30 minutes. Polymerization is complete when a distinct schlieren line is visible between the gel and isopropanol.

- Prepare for Stacking Gel: Pour off the isopropanol and rinse the top of the gel with deionized water to remove any residual.

- Prepare and Cast Stacking Gel: Prepare the stacking gel solution (see table below), adding TEMED last. Pour the solution directly onto the polymerized resolving gel.

- Insert Comb: Carefully place the comb into the stacking gel solution, avoiding air bubbles. Allow to polymerize for 20-30 minutes.

- Final Preparation: Gently pull the comb straight up to remove it. Rinse the wells thoroughly with deionized water to remove any unpolymerized acrylamide.

Quantitative Data for Gel Recipes Volumes are for one mini-gel cassette. Adapt as needed for your specific system.

Resolving Gel (e.g., 10% formulation) [20]:

| Reagent | Volume |

|---|---|

| 40% Acrylamide/Bis | 2.5 ml |

| 1.5M Tris pH 8.8 | 2.5 ml |

| dI-H₂O | 4.85 ml |

| 10% SDS | 100 µl |

| 10% APS | 50 µl |

| TEMED | 5 µl |

Stacking Gel (e.g., 4% formulation) [20]:

| Reagent | Volume |

|---|---|

| 40% Acrylamide/Bis | 0.50 ml |

| 0.5M Tris pH 6.8 | 1.26 ml |

| dI-H₂O | 3.18 ml |

| 10% SDS | 50 µl |

| 10% APS | 25 µl |

| TEMED | 5 µl |

Visualization of Workflow and Troubleshooting

The following diagram illustrates the critical pathway to perfect gel casting, integrating key troubleshooting checkpoints to prevent distorted bands.

Within the broader context of troubleshooting distorted protein bands in gel research, mastering sample preparation is a critical first step. Imperfections introduced during denaturation, reduction, or loading will propagate through every subsequent stage of electrophoresis and Western blotting, leading to misinterpretation of results. This guide provides targeted troubleshooting and FAQs to help researchers identify and resolve the most common sample preparation issues that compromise data quality.

Troubleshooting Guide: Common Sample Preparation Issues

The following table outlines specific problems, their root causes in sample preparation, and actionable solutions to achieve sharp, high-quality protein bands.

Table 1: Troubleshooting Distorted Bands Arising from Sample Preparation

| Problem & Symptom | Primary Cause | Recommended Solution |

|---|---|---|

| Smiling Bands (︶-shaped) [21]Bands curve upwards at the edges. | Electrolysis heat causing uneven cooling; gel may be run too quickly [21]. | Run gel at a lower voltage to generate less heat; perform electrophoresis in a cold room or using a cooling unit [21]. |

| Wavy/Lane-to-Lane Banding [22]Uneven, wavy bands across lanes. | Sample salt concentration is too high [22]. | Desalt samples using dialysis, spin columns, or precipitation; ensure salt concentration is <100 mM [22]. |

| Vertical Smiling Bands [22]Bands narrow as they move down the gel. | Over-reduction of proteins (excess DTT or β-mercaptoethanol), creating excessive negative charge and lane-to-lane repulsion [22]. | Use fresh reductants at recommended concentrations; for non-reducing SDS-PAGE, avoid reductants entirely [22]. |

| Hollow/Center-Weak Bands [21]Bands appear white in the center. | Antibody concentrations are too high, and/or HRP activity is too strong, depleting substrate in the center of the band [21]. | Titrate down primary and/or secondary antibody concentrations [21]. |

| Diffuse or Blurry Resolution [22]Bands are poorly defined and spread out. | Incomplete denaturation; proteins not fully unfolded [22]. | Ensure fresh denaturant (SDS) and reductant (DTT/BME) are used; heat samples at recommended temperature (e.g., 95°C) for sufficient time (5-10 min). |

| Protein Degradation (Multiple Extra Bands) [22] | Protease activity in lysate due to improper handling or lack of inhibitors; repeated freeze-thaw cycles [22]. | Always use fresh protease inhibitors; aliquot samples to avoid repeated freeze-thaw cycles [22]. |

Frequently Asked Questions (FAQs)

1. My sample is too viscous or salty after preparation. What can I do? Viscosity is often due to high DNA or salt concentrations. You can reduce viscosity by briefly sonicating your sample or digesting DNA with a nuclease (e.g., Benzonase). For desalting, use methods like dialysis, size-exclusion spin columns (e.g., Sephadex G-25), or protein precipitation and resuspension in an appropriate buffer [22].

2. How can I determine the optimal protein loading volume for my gel? The optimal load depends on gel thickness, well size, and detection method. General guidelines suggest 20–30 µg of total protein for Western blotting from a cell lysate [21]. For precast gels, refer to the manufacturer's specifications; for example, SurePAGE gels can handle volumes up to 80 µl [23]. Always test a range of concentrations in a pilot experiment.

3. Why are my bands not sharp, even with a fresh sample buffer? This could be due to several factors related to sample prep:

- Insufficient Reduction: Ensure your reducing agent (DTT or β-mercaptoethanol) is fresh. Old reductants lose efficacy, preventing complete unfolding of proteins [22].

- Protein Overload: Too much protein can overwhelm the gel matrix, causing band broadening and trailing. Reduce your loading amount [21].

- Presence of Impurities: High lipid or nucleic acid content can interfere with migration. Clarify lysates by centrifugation and consider nucleic acid digestion.

4. What is the difference between reducing and non-reducing SDS-PAGE?

- Reducing SDS-PAGE: Includes a reducing agent (DTT or BME) to break disulfide bonds within and between polypeptide chains. This allows analysis of individual subunits and accurate molecular weight determination.

- Non-reducing SDS-PAGE: Omits the reducing agent. Disulfide bonds remain intact, preserving the native quaternary structure of protein complexes. This is useful for studying multimers or antibodies.

5. My protein of interest is a high molecular weight (>100 kDa). Does sample prep require any special considerations? High molecular weight proteins can be more susceptible to aggregation and incomplete denaturation. Ensure your sample buffer is fresh and consider:

- Longer Denaturation: Heating samples for 10-15 minutes at 95°C.

- Vigorous Mixing: Vortexing during and after heating to ensure complete solubilization.

- Gel Choice: Use low-percentage gels (e.g., 4-12% gradient gels) for better separation of large proteins [23].

Experimental Protocols for Optimal Sample Preparation

Protocol 1: Standard Denaturation and Reduction for SDS-PAGE

This protocol is suitable for most cell lysates and tissue homogenates.

Prepare Sample Buffer (Laemmli Buffer, 2X):

- 125 mM Tris-HCl, pH 6.8

- 4% SDS (w/v)

- 20% Glycerol

- 0.02% Bromophenol Blue

- Store without reductant at room temperature.

Mix Sample and Buffer:

- Combine your protein sample with an equal volume of 2X sample buffer in a microcentrifuge tube.

- For reducing conditions, add β-mercaptoethanol (BME) to a final concentration of 5% (e.g., add 5 µl BME to 95 µl of sample-buffer mix) or DTT to a final concentration of 50-100 mM.

Denature:

- Heat the mixture at 95°C for 5-10 minutes.

Brief Spin:

- Centrifuge at max speed for 1 minute to collect condensation and bring the entire sample to the bottom of the tube.

Load and Run:

- Load the recommended volume (typically 10-30 µl) onto your gel. Avoid loading insoluble debris.

Protocol 2: Desalting and Buffer Exchange via Spin Column

Use this protocol to clean up samples with high salt or contaminating substances [22].

Equilibrate the spin column according to the manufacturer's instructions using your desired final buffer (e.g., low-salt lysis buffer or water).

Apply the protein sample (up to the column's maximum capacity) to the center of the resin bed.

Centrifuge at the recommended speed and time (typically 1-2 minutes at 1000-1500 x g).

Collect the flow-through, which now contains your protein in the new, clean buffer. It is now ready to be mixed with sample buffer.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for Protein Sample Preparation

| Reagent/Material | Function & Importance |

|---|---|

| SDS (Sodium Dodecyl Sulfate) | An ionic detergent that binds to and unfolds proteins, imparting a uniform negative charge that masks the protein's native charge. This allows separation by size alone. |

| DTT (Dithiothreitol) or BME (β-Mercaptoethanol) | Reducing agents that break disulfide bonds between and within cysteine residues, ensuring proteins are fully unfolded into linear chains. |

| Tris-HCl Buffer | Provides a stable pH environment (typically pH 6.8 for sample buffer, pH ~8.8 for resolving gel) critical for protein stability and gel polymerization. |

| Protease & Phosphatase Inhibitors | Added to lysis buffers to prevent the degradation and unintended post-translational modification of proteins after cell disruption. |

| Glycerol | Increases the density of the sample buffer, allowing the sample to sink neatly to the bottom of the gel well during loading. |

| Tracking Dye (Bromophenol Blue) | A small, visible dye that migrates ahead of the proteins, allowing visualization of the electrophoresis progress. |

Troubleshooting Workflow and Diagnostic Guide

The following diagram outlines a logical pathway for diagnosing and resolving sample preparation issues based on the visual appearance of your gel.

Troubleshooting Guides

Guide 1: Troubleshooting Distorted Protein Bands

Distorted bands, such as "smiling" or "frowning" patterns, are a common issue in SDS-PAGE, often revealing problems with the electrophoretic conditions. The table below outlines primary causes related to instrument configuration and their solutions.

| Problem | Primary Cause | Solution |

|---|---|---|

| 'Smiling' Bands (curving upward at sides) [24] | Uneven heat distribution; center of gel hotter than edges (Joule heating) [1] [25]. Excessive power conditions [7] [24]. | Decrease voltage (e.g., from 200V to 150V) [24]. Use a constant current power supply [1]. Run gel in a cold room or with cooling apparatus [25] [5]. |

| 'Frowning' Bands | Incorrect buffer concentration or depleted buffer [1]. | Ensure fresh, correctly prepared running buffer is used [1] [5]. |

| Vertical Streaking | Sample overload [7] [24]. Excessive voltage [24]. | Dilute sample or load less volume [7] [24]. Reduce voltage by ~25% [24]. |

| Wavy Dye Front | Difference in buffer level between inner and outer chambers [7]. Using old or over-diluted running buffer [7]. | Fill both buffer chambers to the electrodes [7]. Use fresh 1X running buffer [7]. |

| Band Spreading Horizontally | Diffusion from wells before current is applied [24]. | Minimize time between loading samples and starting the run [25] [24]. |

Guide 2: Optimizing Voltage, Current, and Temperature

Configuring your power supply and managing temperature are critical for sharp band resolution. The following table provides foundational protocols.

| Parameter | Configuration Principle | Experimental Protocol |

|---|---|---|

| Voltage | Running at excessively high voltage causes overheating, smiling, and smearing [25] [1] [5]. | A standard practice is ~150V for a mini-gel [25]. For precision, run at 10-15 volts/cm of gel length [25]. Use lower voltage for longer run times to improve resolution and minimize heat [25] [1]. |

| Current | A constant current setting helps maintain a uniform temperature by controlling the rate of heat generation [1]. | Set the power supply to constant current mode as recommended for your specific gel system. This stabilizes migration. |

| Temperature | Excessive Joule heating denatures proteins, causes band distortion, and leads to gel smiling [25] [1]. | Run electrophoresis in a cold room (4°C). Alternatively, use an integrated cooling system in the apparatus or place ice packs in the tank buffer [25] [5]. Ensure buffer level is sufficient to act as a heat sink [7]. |

Experimental Workflow for Troubleshooting Distorted Bands

The diagram below outlines a systematic approach to diagnosing and resolving distorted band issues.

Frequently Asked Questions (FAQs)

Why are my protein bands "smiling" and how do I fix it? "Smiling" bands, which curve upward at the sides, are primarily caused by uneven heating across the gel, where the center becomes hotter than the edges (Joule heating) [1] [24]. This can be exacerbated by running the gel at excessive voltage [7]. To resolve this, decrease the running voltage and implement cooling by running the gel in a cold room, using a cooling apparatus, or placing ice packs in the tank buffer [25] [1].

What is the single most important factor for improving band resolution? While several factors are important, the gel concentration (pore size) is the most critical for resolution, as it must be optimized for the size range of your target proteins [1]. Additionally, running the gel at a lower voltage for a longer duration can significantly improve separation and band sharpness [25] [1].

My gel has a wavy dye front. What is wrong? A wavy dye front is often due to uneven buffer levels between the inner and outer chambers of the gel tank or the use of old or improperly diluted running buffer [7]. Ensure both buffer chambers are filled to the level of the electrodes and always use fresh, correctly prepared 1X running buffer [7].

My samples migrated out of the wells before I started the run. What happened? This occurs when there is a significant delay between loading the samples and applying the electric current [25]. Without the current to guide them, the samples diffuse haphazardly out of the wells. To prevent this, start the electrophoresis run immediately after you finish loading all samples [25] [24].

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function |

|---|---|

| Fresh Running Buffer | Ensures correct ion concentration and pH for proper current flow and protein migration. Old or incorrect buffer alters system resistance and causes distortion [1] [5]. |

| Reducing Agents (DTT, BME) | Fresh DTT or beta-mercaptoethanol breaks protein disulfide bonds, ensuring complete denaturation and preventing re-oxidation that causes smearing and ghost bands [7] [5]. |

| Glycerol (in Sample Buffer) | Increases the density of the sample, causing it to sink to the bottom of the well during loading and preventing leakage and spillover [26]. |

| Protease Inhibitors | Added during sample preparation to prevent protein degradation by proteases, which is a common cause of smearing in protein gels [1]. |

Technical Support Center: Troubleshooting Guides and FAQs

This technical support center provides targeted troubleshooting guides and FAQs to help researchers address common issues related to protein gel electrophoresis, with a specific focus on the critical role of ladders and controls in diagnosing problems, particularly distorted protein bands.

Troubleshooting Distorted Bands with Essential Controls

Question: My protein bands appear distorted ("smiling" or "frowning"). How can I use my protein ladder and experimental controls to diagnose the cause?

Distorted bands are often a thermal issue caused by uneven heat distribution across the gel during electrophoresis [1]. Your protein ladder acts as the first line of diagnosis. If the bands of the ladder are also distorted, the problem is systemic to the entire gel run, not your specific samples.

Recommendations:

- Reduce the Voltage: Running the gel at a lower voltage minimizes Joule heating, which causes the center of the gel to become hotter than the edges [1].

- Use a Cooling System: Either use a cooled apparatus or reduce the current to manage heat generation [27].

- Ensure Adequate Buffer: Verify that the buffer level is sufficient and consistent across the gel tank to act as a heat sink [27] [1].

- Check Sample Salt Content: High salt concentration in samples can create local heating. Desalt samples or dilute them in a low-salt buffer [27] [1].

Frequently Asked Questions (FAQs)

Q1: What is the difference between a prestained and an unstained protein ladder, and when should I use each?

The choice of ladder is critical for accurate interpretation.

| Feature | Prestained Protein Ladder | Unstained Protein Ladder |

|---|---|---|

| Primary Use | Approximate molecular weight, monitoring run progress, and estimating transfer efficiency during western blotting [28]. | Accurate molecular weight estimation [28]. |

| Migration | Dyes bound to proteins alter migration, resulting in "apparent" molecular weights that can vary between gel chemistries [28]. | Migrates true to its actual molecular weight, providing a precise size reference [28]. |

| Visualization | Bands are visible during and after electrophoresis. | Requires post-electrophoresis staining (e.g., Coomassie, silver stain) to be visualized [28]. |

Q2: Why do I need a positive control lysate, and what should I use?

A positive control lysate is derived from a cell line or tissue sample known to express your target protein [29].

- Purpose: It verifies that your entire experimental procedure—from electrophoresis to transfer and immunodetection—is working correctly. A positive result in this control, even if your test samples are negative, validates your protocol and reagents [29].

- Selection: Check your primary antibody datasheet for a suggested positive control. If none is listed, consult citations for the antibody or use databases like Swiss-Prot or Human Protein Atlas to find a suitable expressing cell line or tissue [29].

Q3: What is the function of a loading control in a western blot?

A loading control is a constitutively expressed protein (e.g., Actin, GAPDH, Tubulin) used to ensure data reliability [29].

Its key functions are:

- Normalization: It confirms that protein loading is equal across all lanes, allowing for accurate quantification of target protein levels [29].

- Transfer Control: It checks that the transfer from the gel to the membrane was even across the entire gel [29].

- Troubleshooting: It can reveal issues like the "edge effect," where proteins in outer lanes transfer differently from those in the middle [29].

Q4: My protein bands are smeared. My ladder looks fine, but my positive control is also smeared. What does this indicate?

If your ladder is sharp but your samples (including the positive control) are smeared, the problem lies in sample preparation, not the electrophoresis conditions [27] [1].

Recommendations:

- Prevent Degradation: Handle samples gently and keep them on ice to prevent protease activity [1].

- Use Fresh Reducing Agents: Addition of a reducing agent that is not fresh can cause smearing. Reduce samples right before loading [27].

- Ensure Complete Denaturation: Make sure proteins are fully denatured by using fresh sample buffer with sufficient SDS [27] [1].

- Avoid Overloading: Do not overload the well with too much protein [27].

Q5: I see extra bands in my western blot. How can a negative control help diagnose this?

A negative control lysate is from a cell line or tissue sample known not to express your target protein, such as a validated knockout cell line [29].

- Purpose: It checks for non-specific binding of your primary or secondary antibodies. A clean result in the negative control lane (no bands) confirms your antibody is specific. Any bands in this lane indicate non-specific binding or antibody cross-reactivity [29].

- Additional Control: A "no primary antibody" control (secondary antibody only) can further help identify non-specific binding from the secondary antibody [29].

Research Reagent Solutions for Protein Electrophoresis

The following table details essential materials and their functions for reliable protein gel electrophoresis.

| Item | Function | Key Considerations |

|---|---|---|

| Prestained Protein Ladder | Approximates protein size and visualizes run progress and transfer efficiency [28]. | Not for accurate molecular weight determination. Migration varies by gel system [28]. |

| Unstained Protein Ladder | Provides accurate molecular weight estimation for unknown proteins [28]. | Requires post-stain visualization. Recommended for publication-quality size data [28]. |

| Positive Control Lysate | Verifies protocol and antibody functionality; validates negative results [29]. | Use a lysate from a cell line known to express the target protein [29]. |

| Negative Control Lysate | Identifies non-specific antibody binding and false positives [29]. | A knockout cell line lysate is ideal [29]. |

| Loading Control Antibodies | Detect housekeeping proteins to normalize for protein loading and transfer variations [29]. | Choose a loading control with a molecular weight different from your target protein [29]. |

Experimental Workflow for Diagnosing Band Distortion

This diagram illustrates the logical process of using controls and ladders to troubleshoot distorted and smeared bands in protein gel electrophoresis.

Controls and Their Diagnostic Roles

This diagram summarizes the key controls used in western blotting and the specific issues they help identify.

Systematic Troubleshooting Guide: Diagnosing and Fixing Distorted Protein Bands

This technical support guide provides a systematic, symptom-based approach to diagnosing and resolving common protein band distortions encountered in gel electrophoresis and western blotting.

Frequently Asked Questions

Q1: Why are my protein bands smeared or blurry instead of sharp?

Smeared bands can result from issues at several stages, including sample preparation, gel running conditions, or over-transfer.

- Possible Cause 1: Improper Gel Running Conditions. Running the gel at too high a voltage can cause overheating and smeared bands [30].

- Possible Cause 2: Protein Degradation. Proteases in the sample can partially digest proteins if the heating step is delayed after adding sample buffer [10].

- Possible Cause 3: Over-transfer during Western Blotting. Transferring for too long can cause proteins to move completely through the membrane [31].

- Possible Cause 4: Protein Overload. Loading too much protein can exceed the gel's resolution capacity, leading to smeared bands [7] [10].

Q2: What causes "smiling" or "frowning" bands that curve upward or downward?

"Smiling" bands, where bands curve upward at the edges, are typically due to uneven heat distribution across the gel [30].

- Primary Cause: Excessive Heat Generation. The electric current flowing through the apparatus generates heat. If this heat is not dissipated evenly, it can cause the gel to expand unevenly, leading to curved band migration [30].

- Troubleshooting: Run the gel at a lower voltage for a longer time, use a cold room, or place ice packs in the gel-running apparatus to ensure even cooling [30].

Q3: Why do I see dumbbell-shaped or barbell-shaped bands?

Dumbbell-shaped bands are often a result of how the sample settles in the well before the run begins.

- Primary Cause: Large Sample Volume. Loading too large a sample volume can cause the sample to diffuse to the sides of the wells. When the run starts, this portion migrates slightly slower, creating a barbell shape [7].

- Troubleshooting: Concentrate your protein sample and load a smaller volume to create a "thinner" starting zone in the well [7].

Q4: What leads to distorted bands only in the peripheral lanes of my gel?

This is a classic "edge effect" where the leftmost and rightmost lanes show distorted band patterns [30].

- Primary Cause: Empty Wells. Leaving the outermost wells empty alters the electric field and buffer flow at the edges of the gel, affecting the migration of proteins in adjacent lanes [30].

- Troubleshooting: Load all wells, especially the peripheral ones. If you lack experimental samples, load protein ladder, a control protein, or sample buffer in unused wells [30].

Q5: Why are there unexpected extra bands or a high background?

Non-specific bands or a blotchy background are common issues in western blotting, primarily related to antibody interactions or blocking.

- Possible Cause 1: Non-specific Antibody Binding. The primary or secondary antibody may be binding to unintended proteins or the blocking agent [32] [33].

- Possible Cause 2: Incomplete or Insufficient Blocking. The membrane was not adequately blocked, allowing antibodies to bind non-specifically to the membrane itself [32] [34].

- Possible Cause 3: Antibody Aggregation. Secondary antibodies can form aggregates over time, which appear as flecks or spots on the blot [32].

- Possible Cause 4: Contaminated Reagents or Membrane. Impurities in buffers or handling membranes with bare hands can introduce keratin contamination [7] [10].

Experimental Protocols for Diagnosis and Resolution

Protocol 1: Diagnosing Protein Degradation vs. Protease Activity

To determine if smeared bands are due to protein degradation or active proteases [10]:

- Split your protein sample into two equal parts.

- Add both to SDS-PAGE sample buffer.

- Immediately heat one portion at 95-100°C for 5 minutes.

- Leave the other portion at room temperature for 2-4 hours, then heat it.

- Run both samples on an SDS-PAGE gel and compare.

- If the room-temperature sample shows more smearing or lower molecular weight bands, protease activity is likely. Always heat samples immediately after adding buffer.

Protocol 2: Verifying Transfer Efficiency in Western Blotting

To confirm whether a weak/no signal is due to inefficient protein transfer from the gel to the membrane [32] [34]:

- After transfer, stain the gel with Coomassie Blue to see if protein remains.

- Alternatively, stain the membrane with Ponceau S solution (reversible) to visualize transferred proteins.

- If transfer is inefficient:

- For large proteins (>100 kDa): Pre-equilibrate the gel in transfer buffer with 0.02–0.04% SDS for 10 minutes before transfer to improve elution [31].

- For small proteins (<10 kDa): Use a membrane with a smaller pore size (0.2 μm instead of 0.45 μm) and consider adding a second membrane to capture proteins that pass through the first [31].

- Ensure proper membrane activation (PVDF in methanol; nitrocellulose in water/transfer buffer).

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent/Material | Function | Key Considerations |

|---|---|---|

| Protease Inhibitor Cocktails | Prevents protein degradation by inhibiting proteases during sample prep. | Essential for preventing smeared bands from sample degradation [34]. |

| PVDF or Nitrocellulose Membrane | Binds transferred proteins for antibody probing in western blot. | PVDF has higher binding capacity; use 0.2 μm pore size for proteins <10 kDa [31]. |

| Tween-20 | Mild detergent added to wash and incubation buffers. | Reduces non-specific antibody binding and background (use at 0.05-0.1%) [32]. |

| Blocking Agents (BSA, Non-fat Milk) | Blocks non-specific binding sites on the membrane. | Non-fat milk can mask some antigens; BSA is preferred for phospho-specific antibodies [32]. |

| Glycine-Based Transfer Buffer | Facilitates protein transfer from gel to membrane. | Methanol concentration (10-20%) is critical; it helps remove SDS but can shrink gel pores [31]. |

| Pre-stained Protein Ladder | Allows visual monitoring of electrophoresis and transfer progress. | Confirm protein separation and approximate transfer efficiency before antibody probing [30]. |

| Dithiothreitol (DTT) or β-Mercaptoethanol (BME) | Reducing agents that break disulfide bonds. | Must be fresh; old reducing agents can cause artifact bands and incomplete unfolding [7]. |

| High-Quality Acrylamide/Bis-acrylamide | Forms the cross-linked matrix of the polyacrylamide gel. | Ensure proper polymerization; inconsistent gel formation leads to poor resolution [30] [7]. |

Troubleshooting Flowchart for Distorted Bands

This diagnostic flowchart helps you systematically identify the root cause of your band issues and find the appropriate solution.

Why Do My Gels Smile or Frown?

In gel electrophoresis, "smiling" bands curve upwards, while "frowning" bands curve downwards. Both artifacts are primarily caused by uneven heat distribution across the gel. When the center of the gel becomes hotter than the edges, samples in the middle lanes migrate faster, creating a smile. Conversely, when the edges are hotter, a frown occurs [1]. This uneven heating, or Joule heating, disrupts the uniform migration of samples, compromising the accuracy and reproducibility of your results [35] [36] [1].

The following workflow outlines a systematic approach to diagnose and resolve this issue.

Troubleshooting FAQs

What causes 'smiling' or 'frowning' bands in my gel?

The primary cause is uneven heating within the gel apparatus, leading to different migration rates in the center versus the outer lanes [35] [1]. Several factors can contribute to this:

- Excessive Voltage: Running the gel at too high a voltage generates excessive Joule heating [35] [36].

- Improper Buffer: Using depleted or incorrect buffer concentration can alter the system's resistance and heating [1].

- Gel Tank Issues: Loose contacts, crooked electrodes, or an uneven buffer level create a non-uniform electric field [36] [1].

- Sample Composition: High salt concentrations in samples create local zones of high conductivity, distorting the electric field and causing localized heating and band distortion [1].

How can I prevent uneven heating in my gels?

You can mitigate uneven heating through several key strategies:

- Optimize Voltage: Run the gel at a lower voltage for a longer duration [35] [1]. A standard practice for protein gels is 10-15 volts per cm of gel length [35].

- Apply Active Cooling: Perform electrophoresis in a cold room or use an ice pack inside the running apparatus to dissipate heat [35].

- Use Constant Current: If available, use a power supply with a constant current mode, which helps maintain a more uniform temperature [1].

- Ensure Proper Setup: Always use fresh running buffer and verify that the buffer level is consistent and the gel is properly submerged and aligned [36] [1].

My gel has a 'smile.' Can I still use the data?

The usability of data from a distorted gel depends on the severity and the requirement for precise molecular weight determination.

- For Qualitative Analysis: If the experiment only requires confirming the presence or absence of a band (e.g., a PCR product check), a slight smile may be acceptable.

- For Quantitative Analysis: For applications requiring accurate sizing or quantification (e.g., differential expression analysis), smiling or frowning bands introduce significant error. It is strongly recommended to repeat the experiment after addressing the root cause [1].

The table below summarizes the characteristics and primary corrective actions for each type of distortion.

| Characteristic | 'Smiling' Bands | 'Frowning' Bands |

|---|---|---|

| Band Shape | Curved upwards (like a U) | Curved downwards (like an inverted U) |

| Migration Pattern | Middle lanes migrate faster than outer lanes | Outer lanes migrate faster than middle lanes |

| Primary Cause | Center of the gel is hotter than the edges [36] [1] | Edges of the gel are hotter than the center |

| Key Solution | Reduce voltage; Apply cooling to the center [35] | Ensure even buffer level and contact; Check for edge effects |

Research Reagent Solutions

The following table lists key reagents and materials essential for preventing gel distortions.

| Reagent/Material | Function & Importance | Troubleshooting Tip |

|---|---|---|

| Running Buffer (e.g., TAE, TBE, SDS-PAGE Buffer) | Maintains pH and ionic strength for current flow; depleted buffer alters resistance and causes heating [35] [1]. | Always prepare fresh buffer at the correct concentration. Do not re-use buffer excessively. |

| Power Supply | Provides the electric field; units with constant current mode help manage heat generation [1]. | Use the constant current setting for more uniform temperature control during longer runs. |

| Cooling Apparatus | Actively dissipates heat generated during electrophoresis. | For protein gels, run in a cold room or use a built-in cooling unit [35]. For DNA gels, an ice pack can be used in the tank. |

| Pre-cast Gels | Ensure consistent gel polymerization and thickness, minimizing internal defects that cause uneven fields. | Follow manufacturer instructions for compatible buffers and voltage limits. |

In protein gel electrophoresis, sharp, well-defined bands are the hallmark of a successful experiment. Smearing—the appearance of diffuse, fuzzy bands—is a common frustration that compromises data integrity and hinders scientific progress. For researchers in drug development, where quantitative analysis is paramount, smearing can obscure critical results related to protein purity, identity, and expression. This guide addresses the three core culprits of smearing—sample degradation, overloading, and improper denaturation—providing clear, actionable solutions to achieve publication-quality gels.

Troubleshooting Guide: Diagnosing and Correcting Smearing

The table below outlines the primary causes of smearing and their respective solutions. Use this guide for quick diagnosis and remediation.

| Primary Cause | Specific Problem | Recommended Solution |

|---|---|---|

| Sample Degradation [1] | Protease activity; improper sample handling. | Use fresh protease inhibitors; keep samples on ice; avoid repeated freeze-thaw cycles; ensure sterile reagents [2]. |

| Sample Overloading [2] | Loading too much protein (>0.2 µg per mm well width). | Load a lower protein concentration (e.g., 10-50 µg total per lane); use a comb with narrower, deeper wells [2] [37]. |

| Improper Denaturation [2] | Incomplete unfolding of proteins by SDS. | Heat samples at 95°C for 5 minutes in Laemmli buffer containing SDS and a reducing agent (e.g., DTT, β-mercaptoethanol) [38] [37]. |

| Incorrect Gel Conditions [1] | Gel percentage is wrong for target protein size. | Use a lower % gel for large proteins, higher % for small proteins; for broad size ranges, use a gradient gel (e.g., 4-20%) [14]. |

| Electrical Issues [39] | Voltage is too high, generating excessive heat. | Run the gel at a lower voltage (e.g., 10-15 V/cm); use constant current mode if available; run in a cold room or with a cooling pack [1] [39]. |

| High Salt Concentration [2] | High ionic strength in sample buffer distorts electric field. | Desalt samples via dialysis, precipitation, or desalting columns; dilute sample in nuclease-free water before adding loading buffer [2] [14]. |

Decision Workflow for Troubleshooting Smear

For a systematic approach to diagnosing smearing, follow the logic in this diagram.

Essential Experimental Protocols

Protocol 1: Optimized Sample Preparation to Prevent Degradation and Ensure Denaturation

This protocol is critical for eliminating smearing caused by sample integrity issues [37].

- Lysis: Lyse cells or tissues in an appropriate, ice-cold lysis buffer (e.g., RIPA, NP-40) supplemented with a fresh, complete protease inhibitor cocktail.

- Clarification: Centrifuge the lysate at 14,000 x g for 15 minutes at 4°C to remove insoluble debris. Transfer the supernatant to a new tube.

- Quantification: Determine protein concentration using a compatible assay (e.g., BCA or Bradford).

- Denaturation: Dilute the protein sample in Laemmli SDS-sample buffer to a final 1X concentration. A standard recipe includes:

- Heat Denaturation: Heat the samples at 95°C for 5 minutes to ensure complete protein unfolding [37].

- Brief Spin: Centrifuge the samples briefly to bring down condensation before loading the gel.

Protocol 2: SDS-PAGE Gel Casting and Electrophoresis

A properly prepared and run gel is fundamental to sharp bands [37].

- Gel Selection: Choose an appropriate acrylamide percentage for your target protein size. For most applications, a 10% resolving gel is standard. Use gradient gels (e.g., 4-20%) for separating a wide range of molecular weights [14].

- Casting the Gel:

- Resolving Gel: Mix components as shown in the table below. Pour between clean glass plates and overlay with water-saturated butanol or isopropanol for a flat meniscus. Allow to polymerize completely.

- Stacking Gel: Once polymerized, pour off the overlay, prepare the stacking gel solution, and pour on top of the resolving gel. Insert a clean comb without introducing bubbles.

- Electrophoresis:

- Assemble the gel cassette in the tank and fill with fresh SDS-running buffer (e.g., Tris-Glycine-SDS).

- Load samples and an appropriate molecular weight marker.

- Apply a constant voltage. For a standard mini-gel, 100-150V is typical. Running at a lower voltage for a longer time generates less heat and can improve resolution [39].

Sample Gel Formulation (for one 10% mini-gel)

| Component | Resolving Gel (10%) | Stacking Gel (4%) |

|---|---|---|

| Water | 2.5 mL | 1.625 mL |

| Acrylamide (40%) | 1.25 mL | 0.25 mL |

| Separating Buffer (4X) | 1.25 mL | - |

| Stacking Buffer (4X) | - | 0.625 mL |

| 10% Ammonium Persulfate (APS) | 50 µL | 25 µL |

| TEMED | 5 µL | 2.5 µL |

Add APS and TEMED last to initiate polymerization [37].

The Scientist's Toolkit: Research Reagent Solutions

| Reagent | Function in Preventing Smearing |

|---|---|

| Protease Inhibitor Cocktails | Prevents protein degradation by inactivating proteases released during cell lysis, a primary cause of smearing [1]. |

| Dithiothreitol (DTT) or β-Mercaptoethanol | Reducing agents that break disulfide bonds within and between proteins, ensuring complete unfolding and preventing aggregation [38] [40]. |

| High-Purity SDS | Anionic detergent that binds to and unfolds proteins, masking their intrinsic charge and creating a uniform charge-to-mass ratio for separation by size, not shape [38]. |

| Laemmli Sample Buffer | A ready-to-use buffer containing SDS, reducing agents, and tracking dye to properly denature and prepare samples for loading [37]. |

| Tris-Glycine-SDS Running Buffer | Maintains the correct pH and ion concentration during electrophoresis, ensuring stable current flow and proper protein migration [39]. |

Frequently Asked Questions (FAQs)

Q1: My samples were heated at 95°C, but I still see smearing. What else could it be? Even with heating, smearing can occur if your sample buffer is old or the reducing agent (DTT/β-ME) has oxidized and lost effectiveness. Prepare fresh sample buffer and use fresh aliquots of reducing agents. Additionally, if your protein is particularly hydrophobic or membrane-bound, it may require the addition of urea (4-8 M) to the sample buffer to maintain solubility and prevent aggregation [14].

Q2: I've checked my sample and gel conditions, but I still get a faint smear. Could it be the equipment? Yes. If the electrodes in your tank are crooked or the gel is not seated properly, it can create an uneven electric field, leading to distorted or smeared bands [1]. Ensure your apparatus is clean and correctly assembled. Also, confirm that the buffer is fresh and at the correct concentration, as depleted buffer can cause similar issues [39].