Mastering SDS-PAGE for Accurate Protein Molecular Weight Determination: A Complete Protocol and Troubleshooting Guide

This comprehensive guide details the Sodium Dodecyl Sulfate Polyacrylamide Gel Electrophoresis (SDS-PAGE) protocol for precise protein molecular weight determination, tailored for researchers, scientists, and drug development professionals.

Mastering SDS-PAGE for Accurate Protein Molecular Weight Determination: A Complete Protocol and Troubleshooting Guide

Abstract

This comprehensive guide details the Sodium Dodecyl Sulfate Polyacrylamide Gel Electrophoresis (SDS-PAGE) protocol for precise protein molecular weight determination, tailored for researchers, scientists, and drug development professionals. It covers the foundational principles of protein denaturation and separation, a step-by-step methodological workflow from sample preparation to analysis, systematic troubleshooting for common issues like poor band separation, and validation strategies including comparison with advanced techniques like CE-SDS. The article also explores critical applications in biopharmaceutical development, such as biosimilarity assessment and purity analysis, providing an essential resource for robust and reproducible protein analysis in research and quality control.

The Core Principles of SDS-PAGE: How Proteins are Separated by Molecular Weight

In molecular weight determination research, Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE) stands as a fundamental technique for protein analysis. The critical component enabling this method is SDS, which performs two essential functions: complete protein denaturation and impartment of a uniform negative charge. This dual role allows researchers to separate proteins based primarily on molecular weight rather than inherent charge or structural properties. Within the broader thesis context of SDS-PAGE protocol optimization, understanding SDS's mechanism provides the foundation for accurate protein characterization, purity assessment, and downstream applications in drug development [1] [2].

Core Principles of SDS Action

SDS operates through specific molecular interactions that transform native proteins into linearized, uniformly charged molecules amenable to electrophoretic separation by mass.

Protein Denaturation Mechanism

SDS molecules contain a hydrophobic tail and an ionic head group, enabling interactions with both non-polar and polar protein regions [2]. The hydrophobic regions interact with and unfold hydrophobic protein domains, while the ionic portions disrupt non-covalent interactions maintaining secondary and tertiary structures [2]. This results in the denaturation of protein molecules to their primary structure, effectively linearizing the polypeptide chains.

Imparting Uniform Negative Charge

As a potent anionic detergent, SDS binds to hydrophobic regions of proteins in a constant ratio of approximately 1.4 g SDS per 1 g of protein [1] [2]. This binding confers a uniform negative charge to all protein molecules, effectively nullifying their intrinsic charge differences that depend on amino acid composition and pH [2]. The resulting charge-to-mass ratio becomes essentially identical across different proteins, ensuring migration in an electric field correlates directly with molecular weight rather than native charge characteristics [1].

Table 1: Core Functions of SDS in Protein Electrophoresis

| Function | Mechanism | Outcome |

|---|---|---|

| Protein Denaturation | Hydrophobic interactions disrupt 2° and 3° structure; ionic interactions disrupt non-covalent bonds | Linearized polypeptide chains |

| Charge Uniformity | SDS molecules bind proportionally to protein mass (~1.4:1 ratio) | Identical charge-to-mass ratio across different proteins |

| Molecular Weight-Based Separation | Elimination of charge and structural influences | Migration distance inversely proportional to log(MW) |

Comprehensive SDS-PAGE Protocol for Molecular Weight Determination

Reagent Preparation

Table 2: Essential Research Reagent Solutions for SDS-PAGE

| Reagent/Solution | Composition | Function in Protocol |

|---|---|---|

| SDS Sample Buffer | Tris-HCl, glycerol, SDS, bromophenol blue, with or without β-mercaptoethanol/DTT | Denatures proteins, provides density for loading, tracking dye |

| Reducing Agents (DTT/BME) | Dithiothreitol or β-mercaptoethanol at 0.1-0.5 M | Breaks disulfide bridges for complete unfolding |

| Running Buffer | Tris-base, glycine, SDS (0.1% or 0.0375%) [3] | Conducts current, maintains pH, provides SDS during separation |

| Polyacrylamide Gel | Acrylamide/bis-acrylamide (typically 29:1), TEMED, APS | Sieving matrix for size-based separation |

| Staining Solutions | Coomassie Brilliant Blue, Silver Stain, or fluorescent dyes (SYPRO Ruby) | Visualizes separated protein bands |

Step-by-Step Experimental Methodology

Sample Preparation:

- Combine protein sample with SDS-PAGE sample buffer (typical ratio 3:1 or 4:1) [3]

- For reduced conditions, include 50-100 mM DTT or 5% β-mercaptoethanol [2]

- Heat mixture at 95°C for 5-10 minutes to complete denaturation [1] [2]

- Centrifuge briefly to collect condensation before loading

Gel Preparation and Electrophoresis:

- Prepare resolving gel (typically 8-15% acrylamide) with pH ~8.8 for optimal separation

- Layer with isopropanol to create flat interface during polymerization

- Prepare stacking gel (typically 4-5% acrylamide) with pH ~6.8 to concentrate samples

- Insert comb to create wells for sample loading

- Load prepared samples and molecular weight standards into wells

- Run electrophoresis at constant voltage (100-200V) using Tris-glycine-SDS running buffer until dye front reaches bottom [1]

Visualization and Analysis:

- Stain gel with Coomassie Blue (sensitivity: 50-100 ng) or silver stain (sensitivity: 1 ng) [1]

- Measure migration distances of protein bands and standard proteins

- Plot standard curve of log(MW) versus migration distance (Rf)

- Calculate molecular weight of unknown proteins using standard curve equation: log(MW) = a - b × Rf [1]

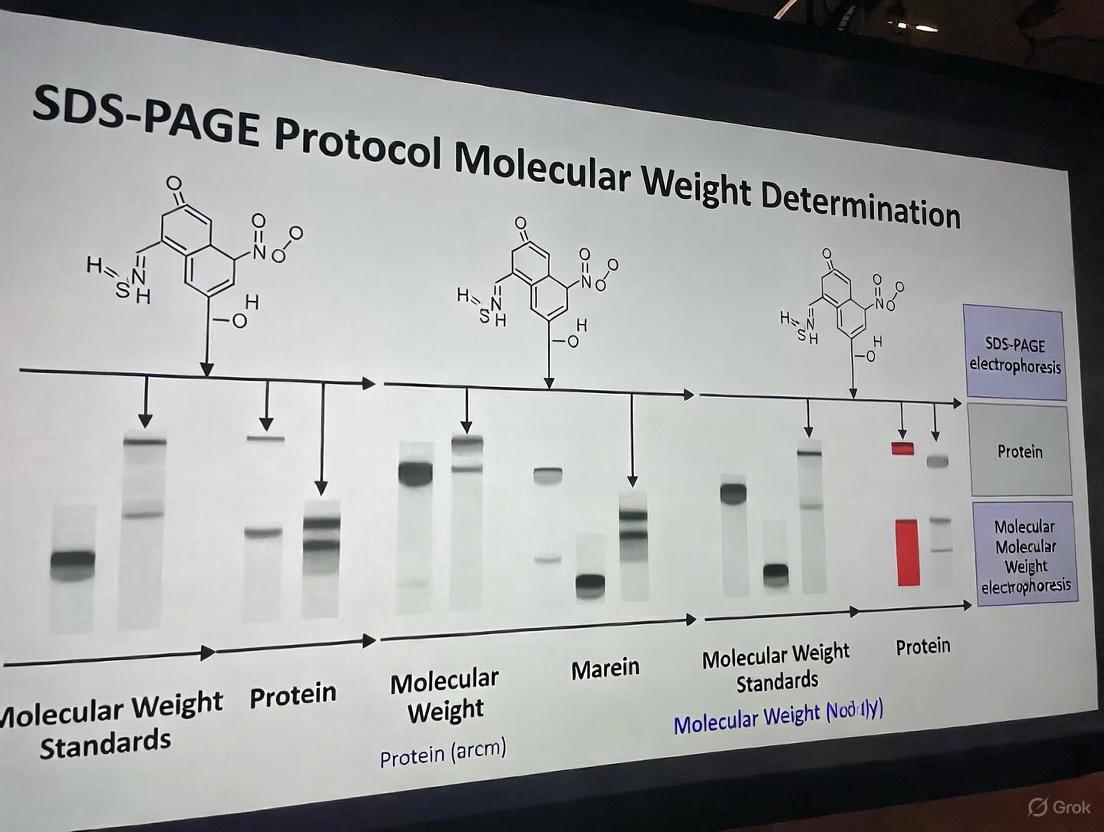

Diagram 1: SDS-PAGE Workflow for Molecular Weight Determination

Technical Considerations and Applications

Critical Experimental Factors

Gel Concentration Selection: The appropriate acrylamide concentration depends on target protein size range. Lower percentage gels (6-10%) better separate high molecular weight proteins (>100 kDa), while higher percentages (12-15%) provide superior resolution for smaller proteins (<50 kDa) [1]. Gradient gels can accommodate broader molecular weight ranges in a single run.

Buffer Composition Variations: Traditional SDS-PAGE uses running buffer with 0.1% SDS, while Native SDS-PAGE (NSDS-PAGE) modifications reduce SDS to 0.0375% in running buffer and eliminate SDS and EDTA from sample buffer to preserve some functional properties [3]. This adaptation demonstrates how SDS concentration manipulation can serve different research objectives.

Research Applications in Drug Development

SDS-PAGE provides critical data throughout biopharmaceutical development pipelines:

- Purity Assessment: Detection of impurity bands during therapeutic protein purification [1]

- Expression Optimization: Comparison of recombinant protein expression levels under various conditions [1]

- Post-Translational Modification Screening: Identification of potential modifications (phosphorylation, glycosylation) through mobility shifts [1]

- Quality Control: Verification of protein integrity in raw materials and final products [4]

- Allergen Detection: Identification of contaminating proteins in biopharmaceutical production systems [4]

Table 3: Troubleshooting Common SDS-PAGE Issues

| Issue | Potential Causes | Solutions |

|---|---|---|

| Poor Resolution | Incorrect gel percentage, improper buffer pH, insufficient stacking | Optimize gel concentration for target MW range, verify buffer pH |

| Band Smiling | Excessive heat during electrophoresis | Reduce voltage, use cooling system during run |

| Atypical Migration | Incomplete denaturation, post-translational modifications | Ensure proper heating (95°C, 5-10 min), use fresh reducing agents |

| High Background | Insufficient washing, over-staining | Optimize staining/destaining times, increase wash steps |

The foundational role of SDS in protein denaturation and charge normalization establishes it as an indispensable reagent for molecular weight determination research. Through its dual mechanisms of action, SDS enables the precise electrophoretic separation that underpins protein characterization across diverse scientific disciplines, particularly in pharmaceutical development where accurate molecular weight assessment is critical for therapeutic protein validation and quality control.

The polyacrylamide gel matrix is the cornerstone of sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE), a fundamental technique for separating proteins based on their molecular weight. This matrix functions as a tunable molecular sieve, enabling high-resolution separation of complex protein mixtures that is critical for molecular weight determination research [5]. The gel is formed through the co-polymerization of acrylamide monomers and the cross-linking agent N,N'-methylenebisacrylamide (Bis), creating a three-dimensional network with precisely controlled pore sizes [5] [6]. The polymerization reaction is catalyzed by ammonium persulfate (APS) and accelerated by the catalyst N,N,N',N'-tetramethylethylenediamine (TEMED) [6].

In SDS-PAGE, the anionic detergent SDS plays a crucial role by binding to proteins at a ratio of approximately 1.4 g SDS per 1 g of protein, which confers a uniform negative charge and denatures proteins into linear chains [5] [6] [7]. This process masks intrinsic charge differences and eliminates the influence of protein shape, ensuring that separation occurs primarily based on molecular size as proteins migrate through the gel matrix under an electric field [5] [7]. The discontinuous buffer system, comprising stacking and separating gels with different pore sizes and pH values, further enhances separation resolution by initially concentrating protein samples into sharp bands before they enter the separating gel [5] [6].

The Scientist's Toolkit: Essential Reagents and Materials

Successful SDS-PAGE requires precise preparation and understanding of key reagents. The table below details essential materials for polyacrylamide gel electrophoresis.

Table 1: Essential Research Reagents for SDS-PAGE

| Reagent/Material | Function and Purpose |

|---|---|

| Acrylamide/Bis-acrylamide | Forms the gel matrix; acrylamide polymerizes into chains while bis-acrylamide cross-links them, creating a sieving network with controllable pore size [5] [6]. |

| SDS (Sodium Dodecyl Sulfate) | Anionic detergent that denatures proteins and confers a uniform negative charge, ensuring separation is based on molecular weight rather than native charge or shape [5] [7]. |

| APS & TEMED | Ammonium persulfate (APS) and N,N,N',N'-Tetramethylethylenediamine (TEMED) catalyze and accelerate the gel polymerization reaction [6] [8]. |

| Tris-HCl Buffers | Provides the appropriate pH environment for electrophoresis (e.g., pH 6.8 for stacking gel, pH 8.8 for separating gel) [6]. |

| Tris-Glycine-SDS Running Buffer | Conducts current and maintains pH during electrophoresis; essential for protein migration [6]. |

| Reducing Agents (DTT, β-mercaptoethanol) | Breaks disulfide bonds in proteins, ensuring complete denaturation and linearization [5]. |

| Laemmli Sample Buffer | Contains SDS, reducing agents, glycerol, and a tracking dye to prepare protein samples for loading [6] [7]. |

| Protein Molecular Weight Marker | A mixture of proteins of known sizes run alongside samples to estimate the molecular weight of unknown proteins [5] [7]. |

| Staining Solutions (Coomassie, Silver Stain) | Used to visualize separated protein bands post-electrophoresis [6] [7]. |

| Dazmegrel | Dazmegrel, CAS:76894-77-4, MF:C16H17N3O2, MW:283.32 g/mol |

| Dazoxiben Hydrochloride | Dazoxiben Hydrochloride, CAS:74226-22-5, MF:C12H13ClN2O3, MW:268.69 g/mol |

Experimental Protocol for SDS-PAGE

This section provides a detailed methodology for casting and running polyacrylamide gels for molecular weight determination.

Gel Casting Procedure

Table 2: SDS-PAGE Gel Recipes for Different Percentages (for 15 mL total volume) [9] [6]

| Component | 8% Resolving Gel | 10% Resolving Gel | 12% Resolving Gel | 5% Stacking Gel |

|---|---|---|---|---|

| 30% Acrylamide/Bis Mix | 4.0 mL | 5.0 mL | 6.0 mL | 2.5 mL |

| 1.5 M Tris-HCl (pH 8.8) | 3.75 mL | 3.75 mL | 3.75 mL | - |

| 1.0 M Tris-HCl (pH 6.8) | - | - | - | 3.78 mL |

| 10% (w/v) SDS | 150 µL | 150 µL | 150 µL | 150 µL |

| Deionized Water | 7.0 mL | 6.0 mL | 5.0 mL | 8.4 mL |

| 10% (w/v) APS | 75 µL | 75 µL | 75 µL | 75 µL |

| TEMED | 7.5 µL | 7.5 µL | 7.5 µL | 15 µL |

10-Step Casting Protocol [9] [6]:

- Assemble Glass Plates: Clean and assemble the gel cassette according to the manufacturer's instructions.

- Prepare Resolving Gel Mixture: In a beaker or flask, combine all components for the resolving gel from Table 2 except APS and TEMED. Mix gently.

- Initiate Resolving Gel Polymerization: Add APS and TEMED to the mixture, swirl gently to combine, and pour immediately between the glass plates, leaving space for the stacking gel.

- Overlay with Solvent: Carefully overlay the gel solution with isopropanol or water to create a flat, even interface.

- Polymerize: Allow the gel to polymerize completely for 20-30 minutes. A distinct schlieren line will appear after polymerization.

- Prepare Stacking Gel Mixture: Pour off the overlay, rinse with water, and prepare the stacking gel mixture (without APS and TEMED).

- Initiate Stacking Gel Polymerization: Add APS and TEMED to the stacking gel, mix, and pour onto the polymerized resolving gel.

- Insert Comb: Immediately insert a clean comb into the stacking gel, avoiding air bubbles.

- Polymerize Stacking Gel: Allow the stacking gel to polymerize for 15-20 minutes.

- Store or Use: The gel can be used immediately or wrapped in moist tissue paper, sealed in plastic film, and stored at 4°C for up to a few weeks.

Sample Preparation and Electrophoresis

- Sample Denaturation: Mix the protein sample with an equal volume of 2X Laemmli buffer (typically containing 4% SDS, 20% glycerol, 0.004% bromophenol blue, 100 mM Tris-HCl pH 6.8, and 10% β-mercaptoethanol) [6]. Heat the mixture at 95-100°C for 5-10 minutes to ensure complete denaturation [6] [8].

- Gel Setup: Place the polymerized gel into the electrophoresis chamber and fill the inner and outer chambers with Tris-glycine-SDS running buffer [6].

- Sample Loading: Centrifuge the denatured samples briefly and load carefully into the wells. Include a well for the protein molecular weight marker [7].

- Electrophoresis Run: Connect the apparatus to a power supply. Run the gel at a constant voltage of 80 V until the dye front enters the resolving gel, then increase to 120 V until the dye front reaches the bottom of the gel [6]. Cooling the apparatus with an ice bath or a cooling unit is recommended to prevent heat-induced artifacts [6].

Application Notes: Molecular Weight Determination and Purity Assessment

Optimizing Separation and Determining Molecular Weight

The choice of gel percentage is critical for achieving optimal resolution of proteins within a specific molecular weight range.

Table 3: Gel Percentage Selection Guide for Optimal Protein Separation [9] [7]

| Size of Protein (kDa) | Recommended Acrylamide Percentage |

|---|---|

| 4 - 40 | 20% |

| 12 - 45 | 15% |

| 10 - 70 | 12.5% |

| 15 - 100 | 10% |

| 25 - 200 | 8% |

To determine the molecular weight of an unknown protein:

- Calculate the Relative Front (Rf) for each band in the standard and sample: Rf = (Migration distance of protein) / (Migration distance of dye front) [6].

- Plot a standard curve using the Rf values of the protein ladder versus the logarithm of their known molecular weights.

- Interpolate the Rf value of the unknown protein band on the standard curve to estimate its molecular weight [5] [6].

Assessing Protein Sample Purity and Integrity

SDS-PAGE is indispensable for evaluating protein sample purity during purification and for analyzing subunit composition [5] [7]. A pure protein sample typically appears as a single, sharp band on the gel. Multiple bands suggest the presence of contaminating proteins, while a smeared appearance may indicate protein degradation or incomplete denaturation [5]. The use of reducing agents like DTT is crucial for analyzing multi-subunit proteins, as it dissociates subunits linked by disulfide bonds, allowing for accurate determination of individual subunit weights [5] [7].

Workflow Visualization

The following diagram illustrates the logical workflow and key separation principles of the SDS-PAGE protocol.

Within the framework of molecular weight determination research, the Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE) protocol is a foundational method. Its resolving power, however, hinges critically on a clever biochemical strategy: the discontinuous buffer system. This system employs two distinct gel layers—stacking and resolving—each with different chemical and physical properties, to concentrate protein samples into extremely sharp bands before separation by size. This technical note details the principle, components, and a standardized protocol for implementing this essential system to achieve high-resolution protein analysis, a cornerstone of drug development and basic research.

Principles of the Discontinuous Buffer System

The discontinuous buffer system is designed to overcome the band-broadening that would occur if a protein sample were applied directly to a resolving gel. It ensures that all proteins enter the resolving gel simultaneously as a thin, concentrated band, which is a prerequisite for sharp final separations [10]. This is achieved through strategic differences in pH, gel pore size, and ionic composition between the stacking and resolving gels [11].

The core mechanism relies on the creation of a steep voltage gradient that herds protein molecules. The system uses three types of ions present in the gel and running buffers [10] [12]:

- Leading Ion: Chloride (Clâ»), from Tris-HCl in the gels. This small, highly mobile anion has a high electrophoretic mobility.

- Trailing Ion: Glycinate (Glyâ»), from glycine in the running buffer. Its charge state is highly dependent on pH.

- Protein Ions: Proteins coated with the anionic detergent SDS, giving them a uniform negative charge.

In the stacking gel (pH ~6.8), glycine from the running buffer (pH ~8.3) exists predominantly in its zwitterionic form, carrying no net charge and thus moving very slowly [10]. The chloride ions, being small and fully charged, move rapidly towards the anode. This creates an ion discontinuity, setting up a narrow, high-voltage gradient between the fast-moving chloride front and the slow-moving glycine front. The SDS-coated proteins, with a mobility intermediate between these two ions, are compressed or "stacked" into a very tight zone as they migrate [10] [13].

When this ion front reaches the resolving gel (pH ~8.8), the environment changes dramatically. The higher pH causes glycine to shed protons and become predominantly the negatively charged glycinate anion, which now has a high electrophoretic mobility [10]. Consequently, the glycinate ions speed past the protein molecules. The proteins, now deposited as a sharp band at the top of the resolving gel and freed from the voltage gradient, begin to separate based on their molecular weight as they migrate through the sieving matrix of the higher-percentage polyacrylamide [10] [11].

Table 1: Composition and Function of Gel Layers in the Discontinuous Buffer System.

| Gel Layer | Typical pH | Acrylamide Concentration | Primary Function | Key Ionic Events |

|---|---|---|---|---|

| Stacking Gel | 6.8 [10] | 4-5% [11] | Concentrate protein samples into a sharp band | Glycine is a zwitterion (slow); Clâ» is the leading ion [10] |

| Resolving Gel | 8.8 [10] | 8-15% (varies by target protein size) [5] | Separate proteins by molecular weight | Glycine becomes glycinate anion (fast); proteins are sieved by size [10] |

The following workflow diagram illustrates the entire process of SDS-PAGE, from sample preparation to final separation.

The Scientist's Toolkit: Essential Reagents and Materials

Successful execution of the discontinuous buffer SDS-PAGE protocol requires a specific set of reagents and equipment. The table below details the key components and their critical functions in the procedure [14] [12].

Table 2: Essential Research Reagent Solutions and Materials for Discontinuous Buffer SDS-PAGE.

| Item | Function / Role in the Protocol |

|---|---|

| Acrylamide / Bis-acrylamide | Forms the cross-linked polyacrylamide gel matrix that acts as a molecular sieve [11] [5]. |

| Tris-HCl Buffer | Provides the buffering capacity at different pH levels (6.8 for stacking, 8.8 for resolving gel) [10]. |

| Sodium Dodecyl Sulfate (SDS) | Anionic detergent that denatures proteins and confers a uniform negative charge, masking intrinsic charge differences [11] [5]. |

| Ammonium Persulfate (APS) & TEMED | Catalytic system that initiates and accelerates the polymerization of acrylamide [11] [5]. |

| Glycine | Key trailing ion in the running buffer; its pH-dependent charge state is fundamental to the stacking mechanism [10]. |

| Sample Loading Buffer (Laemmli Buffer) | Contains SDS, glycerol, a tracking dye, and a reducing agent to denature, charge, and prepare the sample for loading [10]. |

| Protein Molecular Weight Marker | A mixture of proteins of known sizes run alongside samples to estimate the molecular weight of unknown proteins [11] [5]. |

| Coomassie Brilliant Blue Stain | Anionic dye that binds to proteins non-specifically, allowing visualization of separated bands post-electrophoresis [14]. |

| Vertical Gel Electrophoresis Unit | Apparatus comprising gel cassettes, buffer chambers, and electrodes to conduct the electrophoresis safely [12]. |

| Power Supply | Provides the controlled electrical current required to drive protein migration through the gel [14]. |

| DB07107 | DB07107 |

| DB-766 | DB-766, CAS:423165-22-4, MF:C34H34N6O3, MW:574.7 g/mol |

Detailed Experimental Protocol

Gel Casting: Resolving and Stacking Gels

Materials:

- 30% Acrylamide/Bis-acrylamide solution (37.5:1)

- 1.5 M Tris-HCl, pH 8.8 (Resolving Gel buffer)

- 1.0 M Tris-HCl, pH 6.8 (Stacking Gel buffer)

- 10% (w/v) Sodium Dodecyl Sulfate (SDS)

- 10% (w/v) Ammonium Persulfate (APS) - prepare fresh

- N,N,N',N'-Tetramethylethylenediamine (TEMED)

- Butanol or water (for overlaying)

- Gel casting apparatus (glass plates, spacers, comb)

Methodology:

- Assemble the gel cassette according to the manufacturer's instructions to create a leak-proof mold.

- Prepare the resolving gel mixture based on the desired percentage for your target protein's molecular weight. A typical 10% resolving gel formula is provided as an example [11]. Table 3 offers a guide for choosing the appropriate gel percentage.

- Mix components gently to avoid introducing air bubbles. Add TEMED last, as it initiates polymerization.

- Pour the resolving gel into the cassette, leaving space for the stacking gel.

- Overlay with water or butanol to create a flat, even interface and prevent oxygen from inhibiting polymerization.

- Allow to polymerize completely (approximately 30 minutes at room temperature). A distinct schlieren line will be visible after polymerization.

- Pour off the overlay, rinse the gel surface with deionized water, and thoroughly remove any residual liquid.

- Prepare the stacking gel (typically 4-5% acrylamide). A standard 5% stacking gel formula is provided in Table 4.

- Pour the stacking gel onto the polymerized resolving gel and immediately insert a clean comb.

- Allow the stacking gel to polymerize for at least 30 minutes before use. Gels can be used immediately or stored wrapped in moist paper towels within a sealed bag at 4°C for a few days.

Table 3: Guidelines for Resolving Gel Percentage Selection Based on Target Protein Size.

| Acrylamide Percentage | Effective Separation Range (kDa) | Common Application |

|---|---|---|

| 8% | 30 - 200 [5] | Separation of high molecular weight proteins |

| 10% | 15 - 100 [5] | Standard separation for a broad range of proteins |

| 12% | 10 - 70 | Standard separation for mid-to-low molecular weight proteins |

| 15% | 5 - 50 [5] | Optimal for low molecular weight proteins |

Table 4: Example Recipes for Discontinuous SDS-PAGE Gels.

| Component | 10% Resolving Gel (for 10 ml) | 5% Stacking Gel (for 5 ml) |

|---|---|---|

| Water | 4.0 mL | 3.4 mL |

| 1.5 M Tris-HCl (pH 8.8) | 2.5 mL | - |

| 1.0 M Tris-HCl (pH 6.8) | - | 0.63 mL |

| 30% Acrylamide Solution | 3.3 mL | 0.83 mL |

| 10% SDS | 0.1 mL | 0.05 mL |

| 10% APS | 0.1 mL | 0.05 mL |

| TEMED | 0.004 mL | 0.005 mL |

Sample Preparation and Electrophoresis

Materials:

- Protein sample

- 2X Laemmli Sample Buffer (contains Tris, SDS, glycerol, Bromophenol Blue, and ß-mercaptoethanol or DTT) [10]

- Heating block or water bath

- Microcentrifuge

Methodology:

- Mix protein sample with an equal volume of 2X Laemmli Sample Buffer. If analyzing reduced samples, include a reducing agent like DTT or ß-mercaptoethanol in the buffer to break disulfide bonds [12].

- Denature the samples by heating at 85-100°C for 2-5 minutes [12]. This ensures complete linearization and SDS binding.

- Briefly centrifuge the samples (e.g., 12,000g for 30 seconds) to collect condensation [14].

- Assemble the gel in the electrophoresis tank and fill the inner and outer chambers with Tris-Glycine-SDS Running Buffer (e.g., 25 mM Tris, 192 mM glycine, 0.1% SDS, pH 8.3) [12].

- Load the samples and protein molecular weight markers into the wells carefully to avoid cross-contamination.

- Run the electrophoresis with constant voltage. For a standard mini-gel, begin at 80-90 V until the dye front enters the resolving gel, then increase to 120-150 V until the dye front reaches the bottom of the gel [14] [12]. Table 5 provides standard electrophoresis conditions.

- Terminate the run and proceed with protein visualization (e.g., Coomassie staining) or downstream analysis like Western blotting.

Table 5: Standard Electrophoresis Conditions for Mini-Gel Systems.

| Parameter | Condition | Notes |

|---|---|---|

| Initial Voltage | 80 - 90 V | Applied while samples are in the stacking gel |

| Final Voltage | 120 - 150 V | Increased after dye front enters the resolving gel |

| Run Time | ~90 minutes | Until dye front reaches the gel bottom [12] |

| Expected Current | Start: 30-40 mA, End: 8-12 mA (per gel) [12] | Varies based on gel size and buffer concentration |

The discontinuous buffer system, with its strategic use of stacking and resolving gels, remains a masterpiece of biochemical engineering that is fundamental to high-resolution SDS-PAGE. By first concentrating disparate protein samples into a sharp, unified band and then resolving them by size in a separate optimized matrix, this technique provides the clarity and precision required for accurate molecular weight determination, purity assessment, and expression analysis. Mastery of the underlying principles and meticulous execution of the protocol detailed herein are indispensable for researchers in molecular biology and drug development, ensuring reliable and reproducible data that drives scientific discovery forward.

Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE) represents a foundational methodology in molecular biology and biochemistry for separating proteins based on their molecular weights. This technique enables researchers to analyze protein samples for purity, estimate molecular mass, and facilitate subsequent analytical procedures such as Western blotting. The successful implementation of SDS-PAGE relies critically on the precise function of several key chemical components that together create the electrophoretic system. This application note details the core reagents—Tris, Glycine, TEMED, and Ammonium Persulfate—within the context of molecular weight determination research, providing researchers and drug development professionals with comprehensive protocols and technical specifications necessary for experimental reproducibility and accuracy.

Core Component Specifications and Functions

The following table summarizes the key reagents essential for SDS-PAGE, their primary functions, and critical properties that researchers must consider for successful experimental design and execution.

Table 1: Essential Research Reagent Solutions for SDS-PAGE

| Reagent | Chemical Formula / Composition | Primary Function in SDS-PAGE | Key Properties & Handling Notes |

|---|---|---|---|

| Tris Buffer | Câ‚„Hâ‚â‚NO₃ / MW: 121.14 g/mol [15] | pH stabilization; charge carrier in electrophoretic system [16] | pKa ~8.1; effective buffering range pH 7-9 [16]; component of both gel and running buffer |

| Glycine | NHâ‚‚CHâ‚‚COOH / MW: 75.07 g/mol [15] | Leading ion in discontinuous buffer system; facilitates protein stacking [16] | Charge state pH-dependent (zwitterion at pH 6.8, anion at pH 8.8) [16]; critical for creating ion fronts |

| TEMED | C₆Hâ‚₆Nâ‚‚ / MW: 116.21 g/mol [17] | Polymerization catalyst with APS; initiates gel formation [17] [16] | Highly flammable; causes severe skin/eye damage [18]; store tightly capped at 4°C [18]; purity ≥99% [17] |

| Ammonium Persulfate (APS) | (NH₄)₂S₂O₈ | Polymerization initiator; generates free radicals for acrylamide cross-linking [16] | Typically prepared as 10% w/v solution in water; short shelf life once dissolved |

| SDS (Sodium Dodecyl Sulfate) | Câ‚â‚‚Hâ‚‚â‚…Oâ‚„NaS / MW: 288.38 g/mol [15] | Protein denaturant; confers uniform negative charge [16] | 1% w/v in running buffer [15]; unfolds proteins and masks intrinsic charge |

Chemical Properties and Formulations

Quantitative Formulations for SDS-PAGE Buffers

Precise reagent concentrations are critical for establishing the appropriate ionic strength, pH, and electrophoretic conditions required for reproducible protein separation. The following table provides standardized formulations for key SDS-PAGE solutions.

Table 2: Standard SDS-PAGE Buffer Formulations

| Buffer/Solution | Component | Quantity per Liter | Final Concentration | pH | Purpose |

|---|---|---|---|---|---|

| 10X Running Buffer [15] | Tris Base | 30.285 g | 0.25 M | 8.3 [19] | Maintains stable pH during electrophoresis; provides ion conductivity |

| Glycine | 144.4 g | 1.923 M | Creates discontinuous buffer system with Tris | ||

| SDS | 10 g | 1% w/v | Maintains protein denaturation and negative charge during migration | ||

| Sample Loading Buffer [20] | Tris-HCl | - | 62.5 mM | 6.8 | Stabilizes sample pH |

| SDS | - | 2% w/v | Denatures and charges proteins | ||

| Glycerol | - | 35% v/v | Adds density for well loading | ||

| Bromophenol Blue | - | 0.05% w/v | Visualizes migration front | ||

| β-Mercaptoethanol | - | 4% v/v | Reduces disulfide bonds |

Component-Specific Mechanisms in Electrophoresis

Tris (Câ‚„Hâ‚â‚NO₃): This buffering agent maintains the stable pH environment required for consistent electrophoretic mobility. With a pKa of 8.1, Tris provides optimal buffering capacity in the pH range (8.3-8.8) most critical for SDS-PAGE separation [16]. The chloride ions from Tris-HCl in the gel matrix function as leading ions in the discontinuous buffer system, creating the voltage gradient essential for protein stacking at the interface between the stacking and resolving gels.

Glycine (NHâ‚‚CHâ‚‚COOH): Glycine plays a dynamic role in the discontinuous buffer system due to its pH-dependent charge state. In the running buffer (pH 8.3), glycine exists primarily as glycinate anions [16]. Upon entering the stacking gel at pH 6.8, these anions transition to zwitterions with negligible net charge, dramatically reducing their electrophoretic mobility. This creates a trailing ion front that effectively concentrates protein samples into sharp bands before they enter the resolving gel.

TEMED (N,N,N',N'-Tetramethylethylenediamine) and Ammonium Persulfate: These catalysts work in concert to initiate and propagate the free radical polymerization of acrylamide into a cross-linked gel matrix. APS decomposes in aqueous solution to produce sulfate free radicals, which are stabilized by TEMED, an organic base that donates electrons to accelerate the radical formation process [16]. This catalytic system creates the porous polyacrylamide network through which proteins are sieved according to size.

Experimental Protocols

Protocol 1: Preparation of SDS-PAGE Running Buffer (10X)

Objective: Prepare a 10X concentrated running buffer stock solution for SDS-PAGE electrophoresis.

Materials:

- Tris base (MW: 121.14 g/mol)

- Glycine (MW: 75.07 g/mol)

- Sodium dodecyl sulfate (SDS, MW: 288.38 g/mol)

- Distilled water

- Measuring balance, beaker (1-2 L), magnetic stirrer

Methodology:

- Prepare 800 mL of distilled water in a suitable container [15].

- Add 30.285 g of Tris base to the solution and stir until completely dissolved [15].

- Add 144.4 g of Glycine to the solution and stir until completely dissolved [15].

- Add 10 g of SDS to the solution and stir until completely dissolved [15].

- Add distilled water until the final volume reaches 1.0 L [15].

- Store at room temperature; dilute to 1X concentration with distilled water before use.

Technical Notes:

- The final 1X working solution contains 25 mM Tris, 192 mM glycine, and 0.1% SDS at pH approximately 8.3 [19].

- Commercial pre-mixed formulations are available as powder packets that dissolve directly in 500 mL water to yield 1X solution [19].

- Solution should appear clear; if cloudiness appears, warm slightly and mix until clear.

Protocol 2: Polyacrylamide Gel Polymerization

Objective: Catalyze the polymerization of acrylamide solution into a cross-linked gel matrix for protein separation.

Materials:

- Acrylamide/bis-acrylamide solution

- TEMED (N,N,N',N'-Tetramethylethylenediamine)

- Ammonium persulfate (APS)

- Tris-HCl buffer (appropriate pH for resolving or stacking gel)

Methodology:

- Prepare the acrylamide monomer solution with the desired concentration (typically 8-15% resolving gel) in appropriate Tris buffer.

- Add 0.05-0.1% v/v TEMED to the acrylamide solution and mix gently [16].

- Prepare a 10% w/v solution of ammonium persulfate in distilled water.

- Add APS solution to the acrylamide/TEMED mixture to a final concentration of 0.05-0.1% w/v [16].

- Mix gently and quickly pour between glass plates, avoiding bubble formation.

- Allow complete polymerization (typically 20-30 minutes) before use.

Technical Notes:

- Polymerization time varies with temperature and reagent concentrations; higher TEMED/APS concentrations accelerate polymerization.

- TEMED is highly corrosive; use appropriate personal protective equipment including gloves and eye protection [18].

- Oxygen inhibits polymerization; ensure minimal air exposure during mixing and pouring.

- For consistent results, prepare APS solution fresh weekly and store at 4°C.

Safety Considerations for TEMED Handling

TEMED requires special safety precautions due to its hazardous properties [18]:

- Storage: Store tightly capped under nitrogen gas at 4°C, segregated from oxidizing materials and acids [18].

- Handling: Use in well-ventilated areas or fume hoods; avoid contact with skin, eyes, and clothing. Wear impervious protective clothing, gloves, and eye protection [18].

- First Aid: For eye contact, immediately flush with plenty of water for at least 15 minutes and seek medical attention. For skin contact, flush with plenty of soap and water for at least 15 minutes while removing contaminated clothing [18].

- Flammability: Highly flammable liquid and vapor; keep away from heat, sparks, and open flames [18].

System Workflow and Mechanism Visualization

The following diagram illustrates the sequential processes and key component interactions in SDS-PAGE separation:

SDS-PAGE Separation Mechanism and Workflow

The precise interplay of Tris, glycine, TEMED, and ammonium persulfate creates the foundation for reliable SDS-PAGE analysis, enabling accurate molecular weight determination essential for proteomics research and drug development. Tris establishes the stable pH environment, glycine enables the discontinuous buffer system for sharp band formation, while TEMED and ammonium persulfate catalyze the formation of the sieving matrix. Mastery of these components' properties, formulations, and handling requirements—particularly the safety considerations for TEMED—ensures experimental reproducibility and high-quality protein separation. Researchers should adhere to the specified protocols and safety guidelines to optimize their SDS-PAGE results for molecular weight determination applications.

A Step-by-Step SDS-PAGE Protocol and Its Applications in Biomedicine

Within the framework of molecular weight determination research, the Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE) protocol stands as a foundational methodology. The accuracy of molecular weight (MW) estimation hinges critically on the complete denaturation and uniform charge masking of all protein constituents in a sample. SDS-PAGE operates on the principle that the anionic detergent SDS denatures proteins, binding to them to impart a uniform negative charge, thereby rendering their separation dependent almost entirely on polypeptide chain length during electrophoresis [21] [22]. However, intrinsic protein properties and suboptimal sample preparation can compromise this ideal behavior, leading to inaccurate MW estimation, poor resolution, and artifactual results. This application note provides a detailed protocol and strategic framework for optimizing the sample preparation phase—specifically denaturation, reduction, and loading buffer composition—to ensure reliable and reproducible protein separation for precise molecular weight determination.

The Role of Sample Buffer Components

The sample buffer is a critical cocktail of reagents, each designed to overcome specific structural features of native proteins to facilitate their separation based solely on molecular weight. A thorough understanding of each component's function is essential for both troubleshooting and optimization.

Core Components and Their Mechanisms

SDS (Sodium Dodecyl Sulfate): This anionic detergent is paramount for molecular weight-based separation. It acts by binding to the hydrophobic regions of proteins, disrupting hydrogen bonds and van der Waals forces, thereby destroying most of the secondary and tertiary structures [21] [23]. The binding of SDS, on average, confers a uniform negative charge to the polypeptide chains, masking the proteins' intrinsic charge. This results in a consistent charge-to-mass ratio, allowing proteins to migrate through the polyacrylamide gel matrix primarily according to their molecular weight [21] [22]. For complex samples, heating to at least 60°C or higher is recommended to facilitate SDS penetration, particularly for membrane proteins [23].

Reducing Agents (DTT or β-Mercaptoethanol): Covalent disulfide (-S-S-) bonds, common in tertiary and quaternary structures, are not disrupted by SDS alone [23]. Reducing agents such as Dithiothreitol (DTT) or β-mercaptoethanol (BME) are required to cleave these disulfide linkages. They function by reducing the bonds to free sulfhydryl (-SH) groups, thereby breaking down the final vestiges of complex protein structure into individual polypeptide subunits [21] [23]. DTT is often preferred due to its lower odor and greater effectiveness in some denaturing conditions [23].

Glycerol: Added to the sample buffer to increase its density, glycerol ensures that the protein samples sink to the bottom of the gel wells during loading, preventing them from diffusing into the surrounding running buffer [23]. Inadequate glycerol concentration is a common cause of sample leakage from wells [24].

Tracking Dye: A small anionic molecule like bromophenol blue is included to provide a visual reference for the progress of electrophoresis. It migrates ahead of the smallest proteins, and the run is typically stopped once the dye front approaches the bottom of the gel [21] [23].

Buffer (Tris-HCl): The sample buffer contains a buffer, typically Tris at pH 6.8, to maintain a stable pH environment. This is crucial for the stacking process in discontinuous gel systems, where proteins are concentrated into a sharp zone before entering the resolving gel [23].

Table 1: Essential Components of SDS-PAGE Sample Buffer and Their Functions

| Component | Primary Function | Typical Concentration | Role in MW Determination |

|---|---|---|---|

| SDS | Denatures proteins; imparts uniform negative charge [23] | 1-2% [23] | Ensures migration is based on size, not intrinsic charge |

| Reducing Agent (DTT/BME) | Reduces disulfide bonds [21] [23] | 50-160 mM DTT or 0.55 M BME [21] [23] | Breaks multimeric complexes into single polypeptides |

| Glycerol | Increases sample density for well loading [23] | 10-20% [21] [23] | Prevents sample loss and ensures accurate volume loading |

| Tracking Dye | Visualizes migration progress [23] | ~0.05 mg/mL [23] | Monitors electrophoresis without interfering with separation |

| Tris Buffer | Maintains stable pH [23] | 10-100 mM, pH 6.8 [23] | Critical for the stacking gel concentration process |

Optimized Denaturation and Reduction Protocol

The following protocol is designed to achieve complete and consistent denaturation of protein samples for accurate molecular weight analysis. The procedure assumes the use of a standard 2X Laemmli-style sample buffer.

Reagents and Solutions

- 2X Sample Buffer: 2% SDS, 20% glycerol, 20 mM Tris-Cl (pH 6.8), 160 mM DTT (or 0.55 M β-mercaptoethanol), 0.1 mg/mL bromophenol blue [23].

- Protein Sample: Pre-adjusted to a known concentration.

- Molecular Weight Standards: A set of pre-stained or unstained proteins of known molecular weights.

Step-by-Step Procedure

Sample and Buffer Mixing: In a sterile microcentrifuge tube, mix your protein sample with an equal volume of 2X sample buffer [21] [23]. For a pre-prepared lysate already in a sample buffer, add β-mercaptoethanol to a final concentration of 0.55 M (e.g., 1 µL of stock BME per 25 µL of lysate) [21]. Vortex the mixture thoroughly.

Denaturation and Reduction: Place the tightly capped microcentrifuge tubes in a heating block or water bath set to 95°C for 5 minutes [21] [25]. This heating step is critical as it provides the thermal energy required to shake up the molecules, facilitating SDS binding to hydrophobic regions and completing the denaturation process [23].

Cooling and Clarification: After heating, briefly centrifuge the samples for 2-3 minutes at high speed (e.g., 10,000-14,000 x g) in a microcentrifuge. This step pellets any insoluble debris or aggregated material, ensuring a clean supernatant is loaded onto the gel [21].

Gel Loading: Load the clarified supernatant into the wells of a pre-cast or hand-cast polyacrylamide gel. Always include a lane for molecular weight standards. A general guideline for complex mixtures is to load 10–20 µg of total protein for Coomassie staining and 1–10 µg for western blotting, though this may require optimization based on target protein abundance [21] [24] [23].

Electrophoresis: Assemble the electrophoresis unit, fill with 1X running buffer, and run at a constant voltage (e.g., 150-200 V) until the dye front reaches the bottom of the gel [21].

The workflow for the complete sample preparation process is outlined below.

Troubleshooting and Optimization Strategies

Even with a standard protocol, researchers may encounter issues that compromise molecular weight accuracy. The following table addresses common problems and their solutions, with a focus on sample preparation.

Table 2: Troubleshooting Common Sample Preparation Issues in SDS-PAGE

| Problem | Potential Causes | Optimization Strategies |

|---|---|---|

| Smearing or Streaking | Protein aggregation/precipitation; Insufficient heating; Overloading [24] [23] | Ensure fresh reducing agent; Optimize heating time/temperature; Reduce loading amount; Add urea (4-8 M) for hydrophobic proteins [24] |

| Atypical Band Migration | Incomplete denaturation (strong charged proteins); Residual structure [21] [23] | Confirm heating at 95°C; Verify SDS concentration; Use fresh sample buffer; Be cautious with glycoproteins or extreme pI proteins [21] |

| Sample Leaks from Well | Low glycerol density; Air bubbles in well; Overfilled well [24] | Increase glycerol to 10-20%; Rinse wells with buffer to dislodge bubbles; Do not load more than 3/4 of well capacity [24] [23] |

| No or Faint Bands | Underloading; Inefficient transfer (for WB); Protein degradation [24] | Increase loading amount; Check protein concentration with assay; Add protease inhibitors during extraction [24] |

| Multiple Bands for Pure Protein | Proteolysis; Incomplete reduction; Protein isoforms [24] | Work on ice with inhibitors; Use fresh DTT/BME; Research protein post-translational modifications |

Advanced Optimization: The Case of Native SDS-PAGE

For specific applications where retaining metal cofactors or enzymatic activity is desirable alongside size-based separation, a modified approach termed Native SDS-PAGE (NSDS-PAGE) can be employed. This method involves omitting SDS and reducing agents from the sample buffer and eliminating the heating step [3]. Furthermore, the SDS concentration in the running buffer is significantly reduced (e.g., to 0.0375%) [3]. Research has shown that this protocol allows for high-resolution separation while preserving the bound metal ions in metalloproteins and the activity of many enzymes, bridging the gap between fully denaturing SDS-PAGE and native electrophoresis techniques [3].

The Scientist's Toolkit: Key Research Reagent Solutions

Successful and reproducible SDS-PAGE relies on a set of core reagents and materials. The following table details these essential components.

Table 3: Essential Research Reagents and Materials for SDS-PAGE Sample Preparation

| Item | Function/Description | Example Application Note |

|---|---|---|

| SDS (Sodium Dodecyl Sulfate) | Anionic detergent for protein denaturation and charge masking [21] [23] | Use high-purity grade for consistent binding and migration. |

| DTT (Dithiothreitol) | Reducing agent for breaking disulfide bonds; preferred over BME for lower odor [23] | Prepare fresh stock solutions or use stabilized formulations. |

| Protease Inhibitor Cocktails | Prevents protein degradation during and after cell lysis. | Essential for working with sensitive or easily degraded proteins. |

| Protein Assay Kits (e.g., BCA) | Accurately determines protein concentration for equivalent loading [24] | Critical for quantitative comparisons between samples. |

| Precast Gels | Polyacrylamide gels of varying percentages for consistent results [22] [26] | Choose gel percentage based on target protein MW (see Table 1). |

| Molecular Weight Markers | Pre-stained or unstained standards for in-gel MW estimation [21] | Include in every run for calibration and transfer monitoring. |

| DC_517 | DC_517, MF:C33H35N3O2, MW:505.6 g/mol | Chemical Reagent |

| DCG066 | DCG066|G9a Histone Methyltransferase Inhibitor | DCG066 is a novel small-molecule inhibitor of the G9a histone methyltransferase for leukemia research. This product is For Research Use Only. Not for human use. |

The fidelity of molecular weight determination via SDS-PAGE is inextricably linked to the efficacy of the initial sample preparation. Meticulous optimization of denaturation using SDS and heat, coupled with the complete reduction of disulfide bonds using agents like DTT, is non-negotiable for achieving accurate and interpretable results. By understanding the role of each component in the loading buffer, systematically following a robust protocol, and applying targeted troubleshooting strategies, researchers can overcome common pitfalls. This ensures that the separation observed truly reflects the molecular weights of the protein subunits, thereby solidifying the role of SDS-PAGE as a reliable cornerstone in protein analysis for basic research and drug development.

In molecular weight determination research using SDS-PAGE (sodium dodecyl sulfate-polyacrylamide gel electrophoresis), selecting the appropriate polyacrylamide gel concentration is a fundamental prerequisite for obtaining high-resolution protein separation. The principle of SDS-PAGE relies on the fact that proteins denatured by SDS migrate through a polyacrylamide gel matrix at rates inversely proportional to their molecular weights [11]. The gel matrix acts as a molecular sieve, with its pore size determined by the concentration of acrylamide and bisacrylamide; higher percentages create smaller pores that better resolve smaller proteins, while lower percentages with larger pores are optimal for separating larger proteins [11] [27]. This application note provides detailed guidance and protocols to enable researchers to make informed decisions about gel composition based on their protein size of interest, ensuring accurate and reproducible results in molecular weight determination studies.

Protein Size and Gel Percentage Optimization

The relationship between protein size and optimal acrylamide concentration is well-established in electrophoretic separation science. The polyacrylamide gel matrix serves as a molecular sieve, with pore size inversely related to the acrylamide percentage [11] [27]. Higher percentage gels with smaller pores are ideal for resolving lower molecular weight proteins, while lower percentage gels with larger pores provide better separation for higher molecular weight proteins [11] [28]. The following table provides specific guidance for selecting gel percentages based on the molecular weight of the target protein(s).

Table 1: Recommended Gel Percentages for Optimal Protein Separation

| Protein Size Range (kDa) | Recommended Gel Percentage (%) | Separation Characteristics |

|---|---|---|

| 4–40 | 20 | Optimal for very small proteins and peptides [29] [28] |

| 12–45 | 15 | Ideal for small proteins [29] [28] |

| 10–70 | 12–12.5 | Standard range for small to medium proteins [29] [28] |

| 15–100 | 10 | Standard range for medium-sized proteins [29] [28] |

| 25–200 | 7.5–8 | Broad range for medium to large proteins [29] [28] |

| 50–500 | 7 | Wide separation range for large proteins [27] |

| 30–300 | 10 | Intermediate range [27] |

| 10–200 | 12 | Intermediate range [27] |

| 3–100 | 15 | Wide range focusing on small proteins [27] |

| >200 | 5 | Very large proteins [29] |

For samples containing proteins with a broad molecular weight range, gradient gels (e.g., 4-20%) are recommended as they provide a continuous pore size increase from top to bottom, allowing optimal separation of both high and low molecular weight proteins on a single gel [11] [28]. The gradient gel eliminates the need for a stacking gel and can yield sharper protein bands [28].

Experimental Protocol: Casting Discontinuous SDS-Polyacrylamide Gels

Reagent Preparation

Table 2: Essential Reagents for SDS-PAGE Gel Preparation

| Reagent | Function | Safety Considerations |

|---|---|---|

| Acrylamide/Bis-acrylamide (29:1 or 37.5:1) | Forms the porous gel matrix | Potent neurotoxin; always wear gloves [29] |

| Ammonium Persulfate (APS) | Polymerization initiator | Prepare fresh solution for optimal polymerization |

| TEMED (N,N,N',N'-Tetramethylethylenediamine) | Polymerization catalyst | Use in a fume hood; accelerates gel setting |

| Tris-HCl Buffer (pH 6.8 and 8.8) | Maintains pH for stacking and separation | |

| SDS (Sodium Dodecyl Sulfate) | Imparts uniform negative charge to proteins | |

| Butanol or Isopropanol (water-saturated) | Creates an airtight seal over the resolving gel |

Step-by-Step Gel Casting Procedure

Part A: Preparing the Resolving Gel

- Assemble the gel cassette according to manufacturer's instructions, ensuring it is properly sealed to prevent leakage [29].

- Prepare the resolving gel mixture based on the percentage required for your target protein (refer to Table 1). A standard 10% resolving gel recipe for a mini-gel is provided in Table 3 [30].

- Add APS and TEMED last to initiate polymerization, mix thoroughly, and immediately pipette the solution into the gel cassette, leaving appropriate space for the stacking gel (approximately 1 cm below the top of the plates) [29] [31].

- Carefully overlay the gel solution with water-saturated butan-1-ol or water to exclude oxygen and create a flat interface [29] [31].

- Allow complete polymerization for 15-60 minutes at room temperature. A distinct refractive interface will form between the gel and the overlay liquid once polymerization is complete [29].

Part B: Preparing the Stacking Gel

- Pour off the overlay liquid and use a filter paper wick to remove any residual liquid from the set resolving gel [29].

- Prepare the stacking gel solution (typically 4-5% acrylamide). A standard recipe is provided in Table 3 [29] [30].

- Add APS and TEMED to the stacking gel solution, mix, and pipette directly onto the surface of the polymerized resolving gel.

- Immediately insert a clean comb into the stacking gel solution, avoiding air bubbles.

- Allow the stacking gel to polymerize completely for 20-30 minutes [29].

- Carefully remove the comb and rinse wells with deionized water or running buffer to remove any unpolymerized acrylamide.

Table 3: Example Gel Recipes for Discontinuous SDS-PAGE (10 mL Resolving Gel, 5 mL Stacking Gel)

| Reagent | 10% Resolving Gel | 4% Stacking Gel |

|---|---|---|

| dHâ‚‚O | 4.0 mL | 3.05 mL |

| 1.5 M Tris-HCl (pH 8.8) | 2.5 mL | - |

| 0.5 M Tris-HCl (pH 6.8) | - | 1.25 mL |

| 30% Acrylamide/Bis Solution | 3.3 mL | 0.65 mL |

| 10% SDS | 100 µL | 50 µL |

| 10% Ammonium Persulfate (APS) | 50 µL | 25 µL |

| TEMED | 5 µL | 10 µL |

Electrophoresis and Troubleshooting

Sample Preparation and Running Conditions

- Prepare protein samples by diluting them in Laemmli buffer (typically containing SDS and a reducing agent like β-mercaptoethanol or DTT) [30] [31].

- Denature samples by heating at 95°C for 5 minutes [30] [31].

- Load equal amounts of protein (15-40 µg for a mini-gel well) and include an appropriate molecular weight marker in one lane [32] [28].

- Assemble the electrophoresis apparatus and fill with running buffer (e.g., Tris-Glycine-SDS buffer) [30].

- Run the gel at a constant voltage of 100-200V until the dye front reaches the bottom of the gel [30].

Troubleshooting Common Issues

Table 4: Common SDS-PAGE Issues and Solutions

| Issue | Potential Cause | Solution |

|---|---|---|

| Smiling Bands | Buffer/gel overheating during run | Check running voltage; ensure adequate cooling [32] |

| Smeared Bands | Incomplete denaturation or high salt concentration | Add fresh reducing agent; ensure proper heating; reduce salt concentration [32] |

| Vertical Streaking | Sample debris or overloading | Centrifuge samples before loading; reduce protein amount [32] |

| Diffuse Bands | Slow polymerization or old reagents | Prepare fresh APS; ensure correct TEMED amount [29] |

| Uneven Band Migration | Improper buffer formulation | Prepare fresh running buffer with correct pH and composition [32] |

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 5: Key Reagents for SDS-PAGE-Based Molecular Weight Determination

| Reagent/Category | Specific Examples | Function in Protocol |

|---|---|---|

| Lysis Buffers | RIPA Buffer, NP-40 Lysis Buffer, Triton X-100 Buffer | Extract proteins from cells or tissues while maintaining integrity [30] |

| Sample Buffers | Laemmli SDS-Sample Buffer (Reducing/Non-Reducing) | Denature proteins and impart uniform negative charge for separation by size [30] |

| Running Buffers | Tris-Glycine-SDS, MOPS-SDS, MES-SDS | Conduct current and maintain pH during electrophoresis [30] [28] |

| Molecular Weight Markers | Prestained/Unstained Protein Ladders | Provide size calibration for estimating unknown protein molecular weights [11] [28] |

| Polymerization System | Acrylamide/Bis-acrylamide, APS, TEMED | Form the cross-linked polyacrylamide gel matrix [11] [30] |

| Gel Staining Reagents | Coomassie Blue, Silver Stain, SimplyBlue SafeStain | Visualize separated protein bands after electrophoresis [11] |

| Geranic acid | Geranic Acid|High-Purity Reagent for Research | |

| Declopramide | Declopramide|CAS 891-60-1|For Research | Declopramide is for research use only. This small molecule is a DNA repair inhibitor investigated for colorectal cancer and IBD studies. Not for human use. |

In the context of molecular weight determination research using SDS-PAGE, the precise configuration of electrical parameters is fundamental to achieving accurate and reproducible protein separation. Electrophoresis conditions directly influence resolution, band sharpness, and the reliability of molecular weight estimates [7]. This application note details the principles and protocols for optimizing voltage, current, and power settings to ensure high-quality results for researchers, scientists, and drug development professionals.

The separation of proteins in SDS-PAGE relies on the application of an electric field to drive negatively charged protein-SDS complexes through a polyacrylamide gel matrix [7]. The configuration of this electric field—whether maintained at constant current, constant voltage, or constant power—profoundly impacts the rate of migration, heat generation, and ultimately, the clarity of the final protein band pattern [33] [34]. Understanding these parameters is therefore critical for any research involving protein characterization, purity assessment, or western blotting preparation.

Theoretical Foundations of Electrical Parameters

The relationship between voltage, current, and power during electrophoresis is governed by fundamental physical laws. A clear grasp of these relationships allows researchers to make informed decisions when configuring their experiments.

Fundamental Electrical Relationships

Ohm's Law defines the relationship between voltage (V), current (I), and resistance (R): V = I × R [33] [34]. In SDS-PAGE, resistance is influenced by the ionic strength of the buffer, the conductivity of the gel, and temperature [34]. As electrolytes in the running buffer are consumed during the run, resistance typically increases [34].

Power (P), measured in watts, represents the rate of energy conversion and is calculated as: P = I × V [33]. This relationship is critical because the power consumed during electrophoresis is directly converted into heat, a key factor that must be managed for successful experiments [34].

The Role of Heat (Joule Heating)

Heat generation, or Joule heating, is an inevitable consequence of electrophoresis and represents a primary challenge in method optimization [34]. While mild heating can assist in denaturing proteins that were not fully denatured during sample preparation, excessive heat causes multiple problems [33] [34]. These include gel expansion leading to uneven protein migration (manifesting as "smiling" or "frowning" bands), warped gels, and in extreme cases, protein degradation or denaturation that can render proteins undetectable in subsequent western blotting [33] [34] [35]. The management of Joule heating is therefore central to selecting appropriate electrical settings.

Configuration Modes: Principles and Consequences

Modern power supplies offer three primary modes of operation, each with distinct advantages and disadvantages for SDS-PAGE applications. The choice of mode affects run consistency, heat production, and the need for researcher intervention.

Table 1: Comparison of Electrophoresis Configuration Modes

| Configuration Mode | Principles During Electrophoresis | Advantages | Disadvantages | Recommended Applications |

|---|---|---|---|---|

| Constant Current [33] [34] | Current (I) is fixed. As resistance (R) increases, voltage (V) must rise (per V = I × R). Power (P) also increases. | Consistent protein migration rate; predictable run time; sharper bands due to faster runs [34]. | Voltage and heat increase during the run, risking "smiling bands" or warped gels [33] [34]. | When run time consistency is prioritized and cooling methods (ice bath, cold room) are employed [33]. |

| Constant Voltage [33] [34] | Voltage (V) is fixed. As resistance (R) increases, current (I) decreases (per I = V/R). Power (P) decreases. | Safer; limits heat production; multiple chambers can run from one power pack [34]. | Migration slows down late in the run, requiring potential adjustments to running time; may cause diffuse bands [33] [34]. | Standard laboratory practice; when running multiple chambers; for safer operation with less risk of overheating [34]. |

| Constant Power [33] [34] | Power (P) is fixed. As resistance (R) increases, the relationship between V and I fluctuates to maintain P = I × V. | Limits heat production while maintaining more consistent migration than constant voltage [33]. | Unpredictable migration rate; longer run times; potentially diffuse bands [33] [34]. | When heat generation is a major concern but consistent migration is less critical [34]. |

The following decision pathway aids in selecting the appropriate configuration mode based on experimental priorities:

Detailed Experimental Protocol for Molecular Weight Determination

This protocol provides a step-by-step methodology for configuring electrophoresis conditions to achieve optimal protein separation for molecular weight analysis.

Materials and Reagent Solutions

Table 2: Essential Research Reagents and Materials for SDS-PAGE

| Item | Function/Description | Example Formulation/Notes |

|---|---|---|

| Acrylamide/Bis Solution (30%) [36] [14] | Forms the polyacrylamide gel matrix that acts as a molecular sieve. | Neurotoxin in unpolymerized form. Wear gloves and work in a fume hood [36]. |

| Tris-HCl Buffer [36] [14] | 1.5 M, pH 8.8 for resolving gel; 0.5 M, pH 6.8 for stacking gel. Maintains pH for optimal separation. | |

| SDS (Sodium Dodecyl Sulfate) [7] [14] | Anionic detergent that denatures proteins and confers uniform negative charge. | Typically used at 10% solution. Critical for size-based separation [7]. |

| Ammonium Persulfate (APS) & TEMED [36] [14] | Catalyze the polymerization of acrylamide. | Add immediately before casting gels. TEMED quantity affects polymerization rate [36]. |

| Protein Molecular Weight Marker [14] | Contains proteins of known sizes for estimating molecular weight of unknown proteins. | Pre-stained or unstained standards available. Essential for calibration [14]. |

| SDS-PAGE Running Buffer [35] [14] | Conducts current and maintains pH during electrophoresis. | Typically Tris-Glycine with 0.1% SDS. Improper concentration causes poor resolution [35]. |

| Loading Buffer (Laemmli Buffer) [7] [14] | Denatures proteins, adds charge, and provides dye to track migration. | Contains SDS, glycerol, bromophenol blue, and β-mercaptoethanol/DTT [7]. |

| Coomassie Stain Solution [14] | Binds to proteins for visualization post-electrophoresis. | Anionic dye that stains proteins blue. Sensitivity can be enhanced with colloidal stains [14]. |

Step-by-Step Electrophoresis Procedure

Gel Casting: Assemble glass plates and spacers in the casting apparatus. Prepare the resolving gel mixture (e.g., for a 10% gel: 4.1 mL dH₂O, 2.5 mL 1.5 M Tris-HCl pH 8.8, 3.3 mL 30% acrylamide, 50 µL 10% SDS). Just before pouring, add 100 µL 10% APS and 10 µL TEMED, mix without shaking, and pipette between the glass plates. Overlay with ethanol or isopropanol and allow to polymerize for ~30 minutes. Pour off the alcohol, rinse, and remove excess liquid. Prepare the stacking gel (e.g., 2.7 mL dH₂O, 0.5 mL 0.5 M Tris-HCl pH 6.8, 0.8 mL 30% acrylamide, 20 µL 10% SDS), add 40 µL APS and 4 µL TEMED, pour over the resolving gel, insert the comb, and allow to polymerize for at least one hour [36] [14].

Sample Preparation: Mix protein samples with an appropriate volume of loading buffer. Denature the samples by heating at 95–100°C for 5–10 minutes in a boiling water bath or heat block. Centrifuge briefly at 12,000 × g to collect condensation [14].

Apparatus Assembly: Remove the comb and assemble the cast gel into the electrophoresis chamber. Fill both the inner and outer chambers with freshly prepared running buffer [14].

Sample Loading: Load prepared samples and molecular weight markers into the wells. To prevent the "edge effect," which causes distorted bands in peripheral lanes, do not leave any wells empty. If necessary, load ladder or control protein samples in unused wells [35].

Electrophoresis Run Configuration: Connect the chamber to the power supply. The following workflow illustrates the run configuration for optimal results:

- Post-Electrophoresis Analysis: After the run, disconnect the power supply. Remove the gel from the apparatus and carefully separate the glass plates. The gel can be stained for visualization (e.g., with Coomassie Blue for 15 minutes with shaking, followed by destaining until background is clear and bands are visible) or used for downstream applications like western blotting [14].

Troubleshooting and Optimization

Even with a sound protocol, issues can arise. The following table addresses common problems related to electrical configuration:

Table 3: Troubleshooting Common SDS-PAGE Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| "Smiling" or "Frowning" Bands [33] [34] [35] | Excessive heat generation during the run, often from high voltage or current. | Run the gel at a lower voltage for a longer time; use a cold room or ice bath for cooling; consider switching to constant voltage mode [33] [35]. |

| Smeared Bands [35] | Voltage set too high. | Run the gel at 10–15 Volts/cm; use a lower voltage for a longer run time [35]. |

| Poor Band Resolution [35] [7] | Insufficient run time; incorrect gel percentage; improper buffer. | Run the gel until the dye front nears the bottom; choose a gel percentage appropriate for your protein's size (e.g., 8% for 25-200 kDa, 10% for 15-100 kDa); ensure running buffer is correctly prepared [35] [7]. |

| Very Fast Sample Migration [35] | Running buffer too diluted; very high voltage. | Prepare running buffer with the proper salt concentration; adjust voltage to standard practice (~150 V) [35]. |

| Diffuse Bands [34] | Using constant voltage or constant power mode with long run times. | If sharper bands are critical, switch to constant current mode with adequate cooling [34]. |

| Protein Samples Migrating Out of Wells Before Run [35] | Long delay between loading samples and applying current. | Minimize the time between loading the first sample and starting the run [35]. |

The careful configuration of voltage, current, and power settings is a critical component of the SDS-PAGE protocol for molecular weight determination. The choice between constant current, constant voltage, and constant power involves trade-offs between run time consistency, heat management, and band sharpness. By understanding the principles outlined in this application note and adhering to the detailed protocol, researchers can optimize their electrophoresis conditions to obtain reliable, high-resolution protein separation, thereby ensuring the accuracy and reproducibility of their research outcomes in drug development and basic science.

Following the electrophoresis phase of SDS-PAGE, the subsequent processing of the gel is critical for visualizing the separated proteins and determining their molecular weights. This application note details the protocols for staining, visualizing protein bands, and calculating molecular weight, which are essential steps in the broader context of molecular weight determination research for drug development. These procedures allow researchers to analyze protein composition, assess sample purity, and estimate the size of target proteins with an accuracy typically ranging from 5% to 10% [37]. The guidance provided herein is designed to ensure reproducibility and precision in results, which are fundamental requirements for scientific and industrial applications.

Staining and Visualization of Protein Bands

After electrophoresis, proteins within the gel are separated but not visible. Staining is therefore employed to visualize these protein bands for analysis. The choice of staining method depends on the required sensitivity, the amount of protein present, and the need for compatibility with downstream applications.

Staining Protocols

Coomassie Brilliant Blue Staining Coomassie staining is a widely used method due to its simplicity, robustness, and compatibility with subsequent mass spectrometry analysis [7]. The following table summarizes the typical solutions used in the Coomassie staining protocol:

Table 1: Reagents for Coomassie Brilliant Blue Staining

| Solution | Composition | Purpose |

|---|---|---|

| Fixing Solution | 40% Ethanol, 10% Acetic Acid [6] | Precipitates and immobilizes proteins in the gel. |

| Staining Solution | 0.1% Coomassie R-250, 40% Ethanol, 10% Acetic Acid [6] | Binds non-specifically to proteins, creating blue bands. |

| Destaining Solution | 10% Ethanol, 7% Acetic Acid [6] | Removes excess dye from the gel background. |

A standard protocol is as follows [6]:

- Fixation: Following electrophoresis, immerse the gel in Fixing Solution for 30 minutes with gentle agitation.

- Staining: Replace the fixative with Staining Solution and incubate for 1-2 hours with agitation.

- Destaining: Transfer the gel to Destaining Solution. Replace the solution several times over 1-2 hours until the background is clear and protein bands are sharply defined. For faster destaining, the gel can be placed in a sealed container with a few folds of absorbent tissue or a destaining sponge to wick away the dye.

Silver Staining Silver staining offers approximately 100 times greater sensitivity than Coomassie staining, enabling the detection of low-abundance proteins (as little as 0.1 ng) [6]. Given its high sensitivity, it is crucial to use high-purity water and reagents to avoid background staining.

A generalized protocol involves these key steps [6]:

- Fixation: Incubate the gel in a solution of 50% ethanol and 5% acetic acid for 30 minutes.

- Sensitization: Treat the gel with a 0.02% sodium thiosulfate solution for 1 minute.

- Staining: Impregnate the gel with 0.1% silver nitrate (often with formaldehyde) for 20 minutes.

- Development: Develop the stained gel in a solution of 2% sodium carbonate (with formaldehyde) until the desired band intensity is achieved.

- Termination: Stop the development reaction by incubating the gel in 5% acetic acid for 10 minutes.

Table 2: Comparison of Protein Staining Methods

| Parameter | Coomassie Brilliant Blue | Silver Stain |

|---|---|---|

| Mechanism | Non-covalent binding to proteins | Reduction of silver ions to metallic silver on protein surfaces |

| Typical Detection Limit | 10-100 ng [6] | 0.1-1 ng [6] |

| Compatibility with Mass Spectrometry | Excellent [7] | Possible, but requires specific protocols to avoid modification |

| Complexity & Cost | Low | High |

| Time to Complete | 3-5 hours | 4-6 hours |

Gel Documentation and Imaging

Once stained, gels should be imaged promptly to prevent band diffusion [6]. Gel documentation systems are used to capture high-resolution images of the protein bands. For accurate quantification via densitometry, it is critical that the protein band signals are within the linear range of the detection method and are not saturated [38]. If saturation occurs, reducing the exposure time or the amount of protein loaded can rectify the issue.

Molecular Weight Calculation

SDS-PAGE enables the estimation of a protein's molecular weight by comparing its migration distance to that of standard proteins of known molecular weights run on the same gel under identical conditions [37] [31].

Determining Relative Migration Distance (Rf)

The first step is to calculate the Relative Migration Distance (Rf) for each band of the protein standard and for the unknown protein band(s). The Rf is determined using the formula [37] [38] [39]:

Rf = (Migration distance of the protein) / (Migration distance of the dye front)

The migration distance is measured from the top of the separating gel to the center of the protein band of interest. These measurements can be made manually with a ruler or using specialized software [37].

Generating a Standard Curve

A standard curve is created by plotting the Rf values of the protein standards on the X-axis against the logarithm of their known molecular weights (Log(MW)) on the Y-axis [37] [38]. For a well-denatured sample and an appropriate gel percentage, this plot should generate a linear relationship [37]. The stronger this linear relationship (as indicated by an R² value close to 1), the more accurate the molecular weight determination will be [38].

Table 3: Example Data for Standard Curve Generation

| Standard Protein | Molecular Weight (kDa) | Log(MW) | Migration Distance (cm) | Rf Value |

|---|---|---|---|---|

| Myosin | 200 | 2.30 | 1.5 | 0.20 |

| Phosphorylase B | 100 | 2.00 | 2.2 | 0.29 |

| BSA | 70 | 1.85 | 2.9 | 0.39 |

| Ovalbumin | 50 | 1.70 | 3.8 | 0.51 |

| Carbonhydrase | 30 | 1.48 | 5.1 | 0.68 |

| Trypsin Inhibitor | 20 | 1.30 | 6.5 | 0.87 |

Calculating the Unknown Molecular Weight

Once the standard curve is established and a line of best fit is drawn, the equation of this line is used to calculate the molecular weight of the unknown protein.

- Calculate Log(MW): Using the Rf value of the unknown protein, interpolate from the standard curve or use the line's equation to calculate the Log(MW). For a linear plot with equation y = mx + c, where y is Log(MW), m is the slope, and c is the y-intercept, the calculation is straightforward [37].

- Determine Molecular Weight: The final molecular weight is calculated by taking the inverse logarithm of the result: MW = 10^Log(MW) [37].

Example of Calculation: If the linear equation from the standard curve is y = -2.0742x + 2.8 and an unknown protein has an Rf (x) of 0.7084:

- Log(MW) = (-2.0742 × 0.7084) + 2.8 = 1.3305

- Molecular Weight = 10^1.3305 ≈ 21.4 kDa [37]

Workflow and Data Analysis

The entire post-run process, from visualization to final calculation, follows a logical sequence to ensure accurate data generation. The following workflow diagram illustrates the key steps and decision points.

Diagram 1: Post-run analysis workflow for molecular weight determination.

The Scientist's Toolkit: Essential Research Reagents

Successful execution of the post-run protocols requires specific reagents and materials. The following table details the key solutions and their functions.

Table 4: Essential Research Reagents for Post-Run Processing

| Reagent / Material | Function / Purpose |

|---|---|

| Coomassie Staining Solution | Visualizes protein bands by non-covalent binding; suitable for standard sensitivity requirements [7] [6]. |

| Silver Staining Kit | Provides high-sensitivity detection for low-abundance proteins; includes all necessary components for a multi-step process [6]. |

| Destaining Solution | Removes non-specifically bound dye from the gel matrix, reducing background and improving band contrast [6]. |

| Molecular Weight Standards (Ladder) | Contains a mixture of proteins of known molecular weights; essential for generating the standard curve for molecular weight estimation [37] [40]. |

| Gel Documentation System | Captures high-resolution images of stained gels for permanent record keeping and quantitative densitometry analysis [7]. |

| Decylubiquinone | Decylubiquinone, CAS:55486-00-5, MF:C19H30O4, MW:322.4 g/mol |

| 16-Deethylindanomycin | 16-Deethylindanomycin, CAS:106803-22-9, MF:C29H39NO4, MW:465.6 g/mol |

Troubleshooting Common Issues

Several issues can arise during post-run processing that affect the clarity of results and the accuracy of molecular weight determination.

- Smiling or Frowning Bands: Often caused by uneven heating during electrophoresis due to incorrect buffer composition or excessive voltage. Ensure running buffer is correctly prepared and monitor voltage settings [7] [32].