Mastering HPLC Method Development for Impurity Profiling: A Comprehensive Guide for Pharmaceutical Scientists

This comprehensive guide provides researchers, scientists, and drug development professionals with a complete framework for developing, optimizing, troubleshooting, and validating robust HPLC methods specifically for pharmaceutical impurity analysis.

Mastering HPLC Method Development for Impurity Profiling: A Comprehensive Guide for Pharmaceutical Scientists

Abstract

This comprehensive guide provides researchers, scientists, and drug development professionals with a complete framework for developing, optimizing, troubleshooting, and validating robust HPLC methods specifically for pharmaceutical impurity analysis. From foundational principles to advanced validation strategies, this article addresses critical intents including method development workflows, practical applications for forced degradation and stability studies, systematic troubleshooting of common challenges, and ensuring regulatory compliance through comparative assessments. By integrating current industry practices and ICH guidelines, it serves as an essential resource for ensuring drug safety, efficacy, and regulatory approval.

Understanding Impurity Analysis: The Critical Role of HPLC in Drug Safety and Regulatory Compliance

Application Notes

Within the framework of HPLC method development for pharmaceutical analysis, the precise identification, quantification, and control of impurities is a critical determinant of drug safety and quality. Regulatory guidelines, primarily ICH Q3A(R2), Q3B(R2), Q3C(R8), and Q3D, classify impurities based on their origin and toxicological risk, necessitating tailored analytical strategies. This application note delineates the four primary categories of pharmaceutical impurities and their analytical considerations.

Genotoxic Impurities (GTIs): These impurities pose a significant risk due to their potential to damage DNA, even at low concentrations. Their control is guided by ICH M7, which employs a threshold of toxicological concern (TTC) of 1.5 µg/day intake. Analysis requires highly sensitive and specific methods, often involving LC-MS/MS with advanced sample preparation (e.g., derivatization), as concentrations are typically in the ppm to ppb range.

Degradation Impurities: Formed during drug product storage or under stress conditions (e.g., hydrolytic, oxidative, photolytic, thermal). Forced degradation studies (ICH Q1A) are integral to method development, as the resulting chromatograms establish method specificity and the stability-indicating nature of the HPLC method. Quantification follows ICH Q3B thresholds relative to the drug substance.

Process-Related Impurities: Arise from the synthesis, purification, or formulation process. These include starting materials, intermediates, by-products, catalysts (e.g., metal catalysts like Pd, Pt), and reagents. Their profiles are unique to the manufacturing route. Analytical methods must be capable of separating structurally similar synthetic precursors from the active pharmaceutical ingredient (API).

Residual Solvents: Organic volatile chemicals used or produced in API manufacturing, classified per ICH Q3C into Class 1 (to be avoided), Class 2 (to be limited), and Class 3 (low toxic potential). Analysis is typically performed by Gas Chromatography (GC) with headspace sampling, but certain non-volatile solvents may be addressed by HPLC. Control is based on permitted daily exposure (PDE) limits.

Table 1: Key Characteristics and Control Limits for Pharmaceutical Impurity Classes

| Impurity Class | Primary Origin | Key Regulatory Guideline | Typical Analytical Technique | Quantitative Control Threshold (Example) |

|---|---|---|---|---|

| Genotoxic (GTIs) | Synthesis, Degradation | ICH M7 | LC-MS/MS, GC-MS | TTC: 1.5 µg/day (PPM/PPB in API) |

| Degradation | Stability (Stress) | ICH Q1A, Q3B | Stability-Indicating HPLC/UV | Reporting: 0.1%, Identification: 0.2%, Qualification: 0.5%* |

| Process-Related | Chemical Synthesis | ICH Q3A, Q11 | HPLC/UV, HPLC-MS | Reporting: 0.05%, Identification: 0.1%, Qualification: 0.15%* |

| Residual Solvents | Manufacturing Process | ICH Q3C, Q3D | GC-Headspace/FID | Class 1: 2-8 PPM, Class 2: 50-3000 PPM, Class 3: 5000-10000 PPM |

*Thresholds for drug substance (ICH Q3A(R2)); drug product thresholds differ (ICH Q3B(R2)).

Experimental Protocols

Protocol 1: HPLC Method Development for Degradation and Process-Related Impurities

Objective: To develop a validated, stability-indicating reversed-phase HPLC method for the simultaneous quantification of a drug substance and its related impurities.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Sample Preparation: Prepare solutions of the API (0.5 mg/mL) and individual impurity standards (0.5 µg/mL to 5 µg/mL) in a suitable solvent (e.g., diluent: water:acetonitrile, 70:30 v/v).

- Forced Degradation: Subject the API to stress conditions: acid (1M HCl, 70°C, 24h), base (1M NaOH, 70°C, 24h), oxidation (3% H₂O₂, RT, 24h), thermal (105°C, 24h), and photolytic (1.2 million lux hours). Neutralize acid/base stressed samples prior to dilution.

- Initial Scouting: Perform gradient scouting on different columns (C8, C18, phenyl) with mobile phases (e.g., phosphate buffer pH 3.0/acetonitrile vs. ammonium acetate pH 5.0/methanol). Use a lowæµé€Ÿ (e.g., 0.5 mL/min) and a broad gradient (5-95% organic in 60 min). Monitor at multiple wavelengths (210 nm, 254 nm, 280 nm).

- Method Optimization: Based on scouting, select the column and buffer system providing best peak shape and resolution. Optimize gradient profile (slope, hold times), column temperature (30-50°C), and flow rate (0.8-1.2 mL/min) to achieve baseline resolution (R > 2.0) between all critical peak pairs (API and nearest impurity).

- Method Validation: Validate the final method per ICH Q2(R1) for specificity (using stressed samples), linearity (70-130% of specification level), accuracy (spike recovery 90-110%), precision (RSD < 5% for area), limit of detection/quantitation (S/N ≥ 3/10), and robustness (deliberate variations in pH, temperature, organic比例).

Protocol 2: LC-MS/MS Analysis of Genotoxic Impophiles

Objective: To quantify a sulfonate ester GTI in an API at the ppm level.

Procedure:

- Sample Prep (Derivatization): Accurately weigh 100 mg of API into a 10 mL volumetric flask. Add 1 mL of a derivatization reagent (e.g., NaI in acetone for alkylating agents). Sonicate and heat at 50°C for 30 min to form the iodide derivative. Cool, dilute to volume with methanol. Filter through a 0.22 µm PTFE syringe filter.

- LC-MS/MS Conditions:

- Column: C18 (50 x 2.1 mm, 1.7 µm)

- Mobile Phase A: 5mM Ammonium Formate in Water

- Mobile Phase B: Methanol

- Gradient: 20% B to 95% B over 5 min, hold 2 min.

- Flow Rate: 0.3 mL/min

- Injection Volume: 5 µL

- MS Detection: ESI Positive Mode. MRM transitions: Derivative precursor ion > specific product ion. Use a stable isotope-labeled internal standard for quantification.

- Calibration: Prepare calibration standards in API matrix from 0.01 to 1.0 µg/mL (equivalent to 1-100 ppm). Plot peak area ratio (analyte/IS) vs. concentration and perform linear regression.

Diagrams

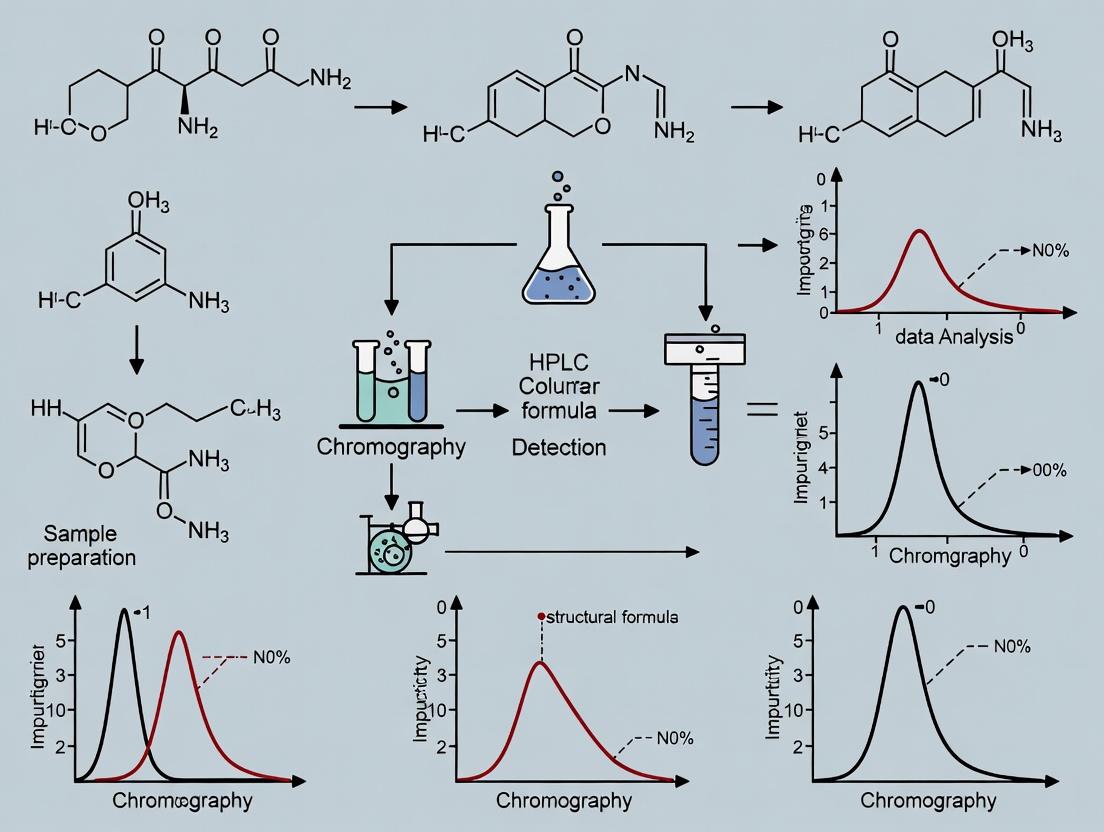

Title: Pharmaceutical Impurity Analysis Decision Workflow

Title: HPLC Method Development for Impurities

The Scientist's Toolkit

Table 2: Essential Research Reagents & Materials for Impurity Analysis

| Item | Function in Impurity Analysis |

|---|---|

| High-Purity HPLC Grade Solvents (Acetonitrile, Methanol) | Mobile phase components; minimize baseline noise and ghost peaks. |

| Buffer Salts (Potassium Phosphate, Ammonium Formate/Acetate) | Control mobile phase pH for consistent ionization and retention. |

| pH Meter & Standard Buffers | Accurate mobile phase pH adjustment critical for reproducibility. |

| Stable Isotope-Labeled Internal Standards (for MS) | Enables accurate quantification by correcting for matrix effects and instrument variability, especially for GTIs. |

| Certified Reference Standards (API, Impurities) | Essential for method development, validation, and peak identification. |

| SPE Cartridges (C18, Mixed-Mode) | Sample clean-up for complex matrices to protect column and enhance sensitivity. |

| 0.22 µm Nylon/PTFE Syringe Filters | Clarify samples prior to HPLC injection, preventing column blockage. |

| U/HPLC Columns (C18, C8, Phenyl, HILIC) | Different selectivity needed to resolve diverse impurity structures. |

| GC Headspace Vials & Septa | Inert, sealed containers for volatile residual solvent analysis. |

| Forced Degradation Reagents (HCl, NaOH, Hâ‚‚Oâ‚‚) | To generate degradation impurities and validate method specificity. |

Impurity control in Active Pharmaceutical Ingredients (APIs) and finished drug products is a cornerstone of drug safety. The ICH Q3A (R2) and Q3B (R2) guidelines establish thresholds for identification, qualification, and reporting of impurities. The following tables summarize the current regulatory thresholds and common impurity sources.

Table 1: ICH Q3A/B Reporting, Identification, and Qualification Thresholds (as per latest revisions)

| Impurity Type / Daily Dose | Reporting Threshold | Identification Threshold | Qualification Threshold |

|---|---|---|---|

| API (Q3A) | ≤ 0.05% | 0.10% or 1.0 mg/day (Lower) | 0.15% or 1.0 mg/day (Lower) |

| Drug Product (Q3B) ≤ 1g/day | 0.1% | 0.5% or 1 mg/day (Lower) | 1.0% or 50 mg/day (Lower) |

| Drug Product (Q3B) > 1g/day | 0.05% | 0.2% or 2 mg/day (Lower) | 0.5% or 50 mg/day (Lower) |

| Genotoxic/Suspected Genotoxic (Q3A/B) | Special Case (≤ TTC*) | Special Case | Special Case (Staged TTC) |

TTC: Threshold of Toxicological Concern (1.5 µg/day). * Staged TTC: Higher limits for short-term exposure.

Table 2: Common Sources and Classes of Pharmaceutical Impurities

| Source | Impurity Class | Example(s) | Typical Risk Level |

|---|---|---|---|

| Synthesis | Starting Materials, Intermediates | Unreacted precursors | Medium-High |

| Synthesis | By-products, Degradants | Isomers, dimerization products | Variable |

| Degradation | Hydrolysis, Oxidation Products | Acid/Base degradants, Peroxides | Medium |

| Process | Catalysts, Solvents Residual | Pd, Pt, Class 1 Solvents (e.g., Benzene) | High |

| Formulation | Excipient Interaction Products | API-Excipient adducts | Low-Medium |

Experimental Protocols

Protocol 1: Forced Degradation Studies for Impurity Profiling

Objective: To elucidate potential degradation pathways of an API and identify major degradation products (potential impurities) under various stress conditions.

Materials: See Scientist's Toolkit (Section 4).

Methodology:

- Sample Preparation: Prepare a 1 mg/mL solution of the API in appropriate solvent (e.g., water, methanol, acetonitrile).

- Stress Conditions:

- Acidic Hydrolysis: Mix 1 mL API solution with 1 mL of 0.1M HCl. Heat at 60°C for 8-24 hours. Neutralize with 0.1M NaOH at specified time points.

- Basic Hydrolysis: Mix 1 mL API solution with 1 mL of 0.1M NaOH. Heat at 60°C for 8-24 hours. Neutralize with 0.1M HCl at specified time points.

- Oxidative Degradation: Mix 1 mL API solution with 1 mL of 3% Hâ‚‚Oâ‚‚. Store at room temperature for 24 hours.

- Thermal Degradation: Expose solid API to 70°C in a dry oven for 1 week.

- Photolytic Degradation: Expose solid API and solution to UV (e.g., 254 nm) and visible light per ICH Q1B conditions for 1 week.

- Analysis: Analyze stressed samples alongside unstressed control using the validated stability-indicating HPLC-UV/MS method (see Protocol 2). Monitor for the appearance of new peaks.

- Peak Identification: Isolate significant degradation products (>0.1%) via preparative HPLC. Characterize structures using LC-MS/MS, NMR, and FTIR.

- Data Interpretation: Correlate degradation products to specific stress conditions to define primary degradation pathways.

Protocol 2: Development and Validation of a Stability-Indicating HPLC Method for Impurity Analysis

Objective: To develop, optimize, and validate a specific, precise, and accurate HPLC method for the separation and quantification of all known and unknown impurities.

Materials: See Scientist's Toolkit (Section 4).

Methodology:

- Method Scouting: Perform screening using different column chemistries (C18, phenyl, HILIC), pH buffers (pH 3.0, 4.5, 7.0), and organic modifiers (acetonitrile, methanol).

- Optimization: Using Design of Experiments (DoE) software, vary key parameters: column temperature (25-45°C), flow rate (0.8-1.2 mL/min), and gradient slope. Optimize for resolution (Rs > 2.0 between all critical peak pairs) and runtime.

- Final Conditions (Example):

- Column: 150 x 4.6 mm, 2.7 µm superficially porous C18.

- Mobile Phase A: 0.1% Formic acid in Water, pH ~2.7.

- Mobile Phase B: Acetonitrile.

- Gradient: 5% B to 95% B over 25 minutes.

- Flow Rate: 1.0 mL/min.

- Detection: UV Diode Array (DAD) 210-400 nm, coupled to Q-ToF MS.

- Injection Volume: 10 µL.

- Validation: Perform per ICH Q2(R1) guidelines.

- Specificity: Demonstrate baseline separation of API from all impurity peaks and forced degradation products. Confirm purity via DAD and MS.

- Linearity & Range: Prepare impurity standards at 6 concentrations from LOQ to 150% of specification level. R² > 0.995.

- Accuracy (Recovery): Spike impurities into API at 50%, 100%, 150% of specification. Mean recovery 95-105%.

- Precision: Repeatability (6 injections at 100% spec, %RSD < 5.0%) and intermediate precision (different day/analyst).

- Limit of Detection/Quantification (LOD/LOQ): Determine via signal-to-noise ratio (S/N) of 3:1 for LOD and 10:1 for LOQ.

Mandatory Visualizations

Diagram Title: Impurity Control Pathway to Patient Safety

Diagram Title: HPLC Method Development Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Impurity Analysis |

|---|---|

| HPLC/UHPLC System (with DAD & MS compatibility) | High-resolution separation and detection of impurities; MS provides structural identification. |

| Columns: C18, Phenyl, HILIC, Chiral phases | Selectivity tuning for separating diverse impurity structures (polar, non-polar, isomeric). |

| MS-Grade Solvents & Buffers (Acetonitrile, MeOH, Formic Acid, Ammonium Acetate) | Ensures low background noise, prevents ion suppression in LC-MS, and provides reproducible chromatography. |

| Impurity Reference Standards | Critical for method validation (accuracy, linearity), identification, and setting quantitative specifications. |

| Forced Degradation Reagents (HCl, NaOH, Hâ‚‚Oâ‚‚) | Used in stress studies to generate degradation impurities and validate method stability-indicating capability. |

| Solid Phase Extraction (SPE) Cartridges | For sample clean-up or isolation of low-level impurities for subsequent NMR/FTIR analysis. |

| Q-TOF or Orbitrap Mass Spectrometer | High-resolution accurate mass (HRAM) measurement for unambiguous elemental composition and structure elucidation of unknown impurities. |

| NMR Spectrometer | Definitive structural characterization for isolated major or critical impurities (e.g., genotoxic). |

| 5,6-Dihydro-2H-pyran-3-carboxylic acid | 5,6-Dihydro-2H-pyran-3-carboxylic acid|CAS 100313-48-2 |

| 1,3,5-trimethyl-1H-pyrazole-4-carbonitrile | 1,3,5-Trimethyl-1H-pyrazole-4-carbonitrile|CAS 108161-13-3 |

Application Notes: The Role of HPLC in Pharmaceutical Impurity Profiling

In the context of a thesis on HPLC method development for pharmaceutical impurities analysis, the supremacy of High-Performance Liquid Chromatography (HPLC) is anchored in its unparalleled ability to resolve, identify, and quantify trace-level impurities in Active Pharmaceutical Ingredients (APIs) and drug products. Recent literature and regulatory guidelines (ICH Q3B(R2)) emphasize the critical need for robust, stability-indicating methods.

Core Principles of Separation

HPLC separation is governed by the differential distribution of analytes between a stationary phase and a mobile phase. Key principles include:

- Selectivity (α): The ability to distinguish between analytes, primarily controlled by the chemistry of the stationary phase and the mobile phase composition.

- Efficiency (N): The degree of peak broadening, quantified by the number of theoretical plates. This is optimized by column particle size (e.g., sub-2µm for UHPLC), column length, and flow rate.

- Retention (k): The hold-up time of an analyte on the column, managed by mobile phase strength.

For impurity analysis, selectivity is paramount to separate structurally similar degradation products and process-related impurities from the main API peak.

Table 1: Comparative Performance of HPLC Method Parameters for Impurity Analysis

| Parameter | Traditional HPLC (5µm) | UHPLC (Sub-2µm) | Impact on Impurity Analysis |

|---|---|---|---|

| Typical Particle Size | 3-5 µm | <2 µm (e.g., 1.7-1.8 µm) | UHPLC provides higher efficiency, leading to better resolution of closely eluting impurities. |

| Operating Pressure | < 400 bar | 600-1000+ bar | Higher pressure enables use of smaller particles for faster, more efficient separations. |

| Typical Column Dimension | 150 x 4.6 mm | 50-100 x 2.1 mm | Shorter, narrower columns reduce solvent consumption and runtime, increasing throughput. |

| Peak Capacity | ~100-200 | ~200-400 | Higher peak capacity improves the ability to resolve complex impurity profiles. |

| Detection Limit (UV) | ~0.1% of API | ~0.05% of API | Improved sensitivity is critical for detecting and quantifying low-level genotoxic impurities. |

Table 2: Common Stationary Phases for Pharmaceutical Impurity Methods

| Stationary Phase Type | Key Chemistry | Typical Application in Impurity Analysis |

|---|---|---|

| Reversed-Phase C18 | Octadecylsilane bonded to silica | Workhorse for most neutral and moderately polar compounds; used in ~80% of pharmaceutical methods. |

| Phenyl-Hexyl or Phenyl | Aromatic ring bonded via hexyl or propyl spacer | Separation of structural isomers and aromatic impurities; offers different selectivity vs. C18. |

| Polar Embedded (e.g., Amide) | Amide or ether group embedded in alkyl chain | Improved retention for polar compounds; useful for early eluting polar degradation products. |

| HILIC | Bare silica or polar functionalized silica (e.g., cyano) | Separation of highly polar, hydrophilic impurities not retained in reversed-phase mode. |

Experimental Protocols

Protocol 1: Systematic Screening for Impurity Method Development

Objective: To rapidly identify starting conditions for the separation of an API and its known impurities.

Materials: See "The Scientist's Toolkit" below. Method:

- Sample Preparation: Prepare separate stock solutions (1 mg/mL) of the API and each available impurity reference standard in a suitable solvent (e.g., methanol/water 50:50). Prepare a spiked mixture containing the API at 0.5 mg/mL and each impurity at 0.1% (0.5 µg/mL) relative to the API concentration.

- Column & Mobile Phase Screening: Use a method screening system with a column oven set to 40°C and a DAD detector (scanning 210-400 nm).

- Step A: Perform three initial gradient runs on three different columns (e.g., C18, Phenyl-Hexyl, Polar-Embedded C18) with a constant mobile phase: A = 10 mM Ammonium Formate (pH 3.0), B = Acetonitrile. Gradient: 5% B to 95% B over 20 minutes. Flow: 1.0 mL/min (for 4.6 mm ID).

- Step B: For the most promising column, repeat the gradient with two additional pH conditions: Ammonium Formate (pH 6.8) and Ammonium Bicarbonate (pH 9.0).

- Data Analysis: Review chromatograms. Select the condition providing the best overall resolution (Rs > 2.0 between all critical peak pairs) and peak shape (Asymmetry Factor between 0.9-1.2). This condition serves as the starting point for fine-tuning.

Protocol 2: Forced Degradation Study to Validate Method Specificity

Objective: To demonstrate the stability-indicating capability of the developed HPLC method.

Method:

- Stress Conditions: Subject the API (~50 mg) to the following conditions in separate vials:

- Acidic Hydrolysis: Add 10 mL of 0.1N HCl. Heat at 60°C for 4 hours. Neutralize with 0.1N NaOH.

- Basic Hydrolysis: Add 10 mL of 0.1N NaOH. Heat at 60°C for 4 hours. Neutralize with 0.1N HCl.

- Oxidative Stress: Add 10 mL of 3% Hâ‚‚Oâ‚‚. Store at room temperature for 24 hours.

- Thermal (Solid): Expose solid API in an oven at 80°C for 72 hours.

- Photolytic: Expose solid API in a photostability chamber to ~1.2 million lux hours of visible and 200 watt-hours/m² of UV light.

- Sample Analysis: Prepare sample solutions from each stressed material at a concentration equivalent to the assay concentration (e.g., 0.1 mg/mL). Inject these samples and an unstressed control sample into the developed HPLC method.

- Specificity Assessment: The method is considered specific if:

- The API peak is pure as confirmed by DAD spectrum (purity angle < purity threshold).

- There is clear baseline separation (Rs > 1.5) between the API peak and all degradation product peaks.

- The mass balance (Sum of %API + %Impurities) is between 98.0% and 102.0%, indicating no co-elution or un-detected degradants.

Visualization: HPLC Method Development Workflow

HPLC Method Development Workflow for Impurities

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for HPLC Impurity Method Development

| Item | Function & Specification |

|---|---|

| UHPLC/HPLC System | Binary or quaternary pump, autosampler, column oven, and Diode Array Detector (DAD). Essential for precise gradient delivery, reproducible injection, and peak purity assessment. |

| C18 Reversed-Phase Column | 100-150 mm x 4.6 mm, 2.7-5 µm particle size. The primary screening column. Sub-2µm particles are used for UHPLC. |

| Alternative Selectivity Columns | Columns with different bonded phases (e.g., Phenyl-Hexyl, Polar-Embedded, HILIC). Crucial for resolving impurities that co-elute on C18. |

| LC-MS Grade Water | Ultra-pure water (< 18 MΩ.cm, TOC < 10 ppb). Minimizes baseline noise and system contamination for sensitive impurity detection. |

| LC-MS Grade Acetonitrile & Methanol | High-purity solvents with low UV absorbance. Primary organic modifiers for reversed-phase chromatography. |

| Ammonium Formate & Acetate | Volatile buffers (e.g., 10-20 mM, pH 3.0-5.0). Provide consistent mobile phase pH for reproducibility; compatible with MS detection. |

| Ammonium Bicarbonate | Volatile buffer for basic pH (e.g., pH 8.0-10.0). Used for separating impurities with ionizable basic groups. |

| Phosphoric Acid / Trifluoroacetic Acid (TFA) | Ion-pairing agents for controlling retention and peak shape of ionizable compounds. Use with caution due to MS incompatibility and potential column aging. |

| Reference Standards | Certified reference materials for the API and known impurities (synthetic, process-related, degradation). Essential for peak identification, method development, and validation. |

| Vial Inserts (Glass, Low Volume) | 100-250 µL inserts for limited sample volumes. Maximize recovery and minimize sample waste during method screening. |

| 5-Amino-1,3-dimethylpyrazole | 5-Amino-1,3-dimethylpyrazole|CAS 3524-32-1 |

| N-Isopropyl-N-methylglycine | N-Isopropyl-N-methylglycine |

Application Notes: Regulatory Framework Synergies

The strategic alignment of ICH guidelines and USP compendial standards forms the foundation for robust HPLC method development in pharmaceutical impurity analysis. These frameworks collectively address method life cycle management from development to validation and routine control.

Table 1: Core Regulatory Focus and Quantitative Thresholds for Impurities

| Regulatory Document | Primary Scope | Key Quantitative Thresholds (Typical) | Direct Impact on HPLC Method Development |

|---|---|---|---|

| ICH Q3A(R2) | Impurities in New Drug Substances | Reporting: >0.05% | Defines required detection sensitivity and reporting levels. |

| Identification: >0.10% or 1.0 mg/day | Sets impurity identification requirements driving method specificity. | ||

| Qualification: >0.15% or 1.0 mg/day | Informs validation requirements for accuracy/precision at thresholds. | ||

| ICH Q3B(R2) | Impurities in New Drug Products | Reporting: >0.05% | Establishes product-specific limits, influencing sample preparation. |

| Identification: >0.10% or 1.0 mg/day (lower for certain doses) | Guides forced degradation studies to generate relevant impurities. | ||

| Qualification: >0.15% or 1.0 mg/day | Defines the required range for validation. | ||

| ICH Q6A | Specifications: Test Procedures & Acceptance Criteria | Sets specification acceptance criteria (e.g., impurity limit NMT 0.5%). | Directly dictates method validation acceptance criteria (precision, accuracy). |

| ICH Q14 | Analytical Procedure Development | Advocates for systematic, science-based development (Quality by Design). | Promotes use of DoE, risk assessment, and defining an Analytical Target Profile (ATP). |

| USP <621> | Chromatography | System suitability parameters (e.g., tailing factor NMT 2.0, plate count >2000). | Provides mandatory system suitability criteria for method operability. |

| USP <1225> | Validation of Compendial Procedures | Defines validation parameter acceptance criteria. | Standardizes validation protocol design and reporting. |

Table 2: Analytical Target Profile (ATP) Elements Derived from Regulatory Frameworks

| ATP Component | Regulatory Driver | Typical HPLC Method Requirement |

|---|---|---|

| Analyte | ICH Q3A/Q3B | Drug substance, known/unknown impurities, degradation products. |

| Objective | ICH Q3, Q6A | Quantify impurities at or below reporting threshold. |

| Detection Limit | ICH Q3 Reporting Threshold | Often ≤0.03% (relative to drug substance concentration). |

| Quantitation Limit | ICH Q3 Reporting Threshold | Often ≤0.05%. |

| Range | ICH Q3 (Reporting to Specification) | Typically from reporting threshold (e.g., 0.05%) to 120-150% of specification limit. |

| Accuracy/Precision | ICH Q3, Q6A, USP <1225> | Accuracy within ±20% at reporting threshold, ±10% at higher levels; Precision RSD <10%. |

| Specificity | ICH Q3 (Identification) | Baseline separation of all known impurities and degradation products. |

| Robustness | ICH Q14, Q2(R2) | Method operable within defined variations of pH, temperature, flow rate, etc. |

Experimental Protocols

Protocol 1: HPLC Method Development with QbD Principles (ICH Q14)

Objective: To develop a validated, stability-indicating HPLC method for the assay and related substances of a new active pharmaceutical ingredient (API), following a systematic, QbD approach aligned with ICH Q14 and ICH Q3A.

I. Define Analytical Target Profile (ATP)

- Purpose: Quantify API and all specified/unspecified impurities (known and unknown) in the drug substance.

- Scope: Release testing and stability studies.

- Performance Requirements: Based on ICH Q3A thresholds for a typical API dose (≥1g/day).

- Reporting Threshold: 0.05%.

- Quantitation Limit (QL): ≤0.03% (signal-to-noise ratio ≥10).

- Detection Limit (DL): ≤0.01% (signal-to-noise ratio ≥3).

- Accuracy: Mean recovery 90-110% for impurities at the specification level.

- Precision: RSD ≤5.0% for assay, ≤10.0% for impurities at specification level.

- Specificity: Baseline separation (resolution Rs >2.0) between all known impurities, degradation products, and the API.

II. Risk Assessment & Critical Method Parameters (CMPs)

- Perform a risk assessment (e.g., Ishikawa diagram) to identify High-Risk Method Parameters.

- High-Risk Parameters (to be studied via DoE): Mobile phase pH (±0.2 units), gradient slope (±5%), column temperature (±5°C), and buffer concentration (±10%).

- Low-Risk Parameters (fixed or univariate study): Wavelength, injection volume, flow rate.

III. Design of Experiments (DoE) for Screening & Optimization

- Screening Design: Use a fractional factorial or Plackett-Burman design to evaluate the impact of the four High-Risk Parameters on Critical Method Attributes (CMAs): Resolution between critical pair, tailing factor of API peak, and total run time.

- Optimization Design: Based on screening results, perform a central composite design (CCD) or Box-Behnken design to model the relationship between key parameters and CMAs. Define the design space.

IV. Method Verification in Design Space

- Select nominal conditions from the design space.

- Prepare system suitability solution containing API and all available impurity standards.

- Verify that method meets all ATP requirements under nominal conditions.

V. Robustness Testing (ICH Q2(R2)/Q14)

- Execute a pre-defined robustness test (e.g., using a fractional factorial design) by deliberately varying CMPs around the nominal set point.

- Evaluate CMAs to confirm method remains within acceptance criteria.

Protocol 2: Forced Degradation Studies for Specificity (ICH Q3, Q14)

Objective: To demonstrate the stability-indicating capability and specificity of the HPLC method by subjecting the API to forced degradation, ensuring separation of degradation products from the API and each other.

Materials: API, 0.1N HCl, 0.1N NaOH, 30% Hâ‚‚Oâ‚‚, solid-state heat chamber, UV light chamber.

Procedure:

- Acidic Hydrolysis: Weigh ~50 mg API into a 50-mL volumetric flask. Add 5 mL of 0.1N HCl. Heat at 60°C for 1-8 hours. Neutralize with 0.1N NaOH. Dilute to volume with diluent.

- Alkaline Hydrolysis: Weigh ~50 mg API. Add 5 mL of 0.1N NaOH. Heat at 60°C for 1-8 hours. Neutralize with 0.1N HCl. Dilute to volume.

- Oxidative Degradation: Weigh ~50 mg API. Add 5 mL of 3% Hâ‚‚Oâ‚‚ (from 30%). Let stand at room temperature for 1-24 hours. Dilute to volume.

- Thermal Degradation (Solid): Spread ~50 mg API in a thin layer in a petri dish. Place in oven at 80°C for 1-7 days. Prepare solution.

- Photolytic Degradation: Spread ~50 mg API in a thin layer. Expose to UV light (e.g., 1.2 million lux hours) in a photostability chamber. Prepare solution.

- Neutral Hydrolysis/Control: Prepare a solution of API in water and heat at 60°C.

- Analysis: Inject all degradation samples and a fresh API standard solution using the developed HPLC method.

- Evaluation: Assess peak purity of the API peak using a PDA detector. Confirm resolution (Rs >2.0) between the API peak and the nearest degradation peak. Document mass balance (assay value + total impurities ~100%).

Visualization

Regulatory Workflow for HPLC Method Development

QbD-Based HPLC Method Development Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for HPLC Impurity Method Development & Validation

| Item/Category | Function & Rationale | Key Regulatory Consideration |

|---|---|---|

| High-Purity Reference Standards | API and available impurity standards for identification, system suitability, and validation. Essential for confirming specificity and accuracy. | ICH Q6A requires use of qualified reference standards. USP <11> provides guidelines. |

| Mass Spectrometry-Compatible Buffers (e.g., Ammonium Formate, Ammonium Acetate) | Volatile buffers for LC-MS/MS studies in impurity identification (supporting ICH Q3A identification thresholds). | Facilitates method structure elucidation capabilities as required by ICH Q3. |

| pH Standard Buffers | For precise calibration of pH meters used in mobile phase preparation. Critical for robustness and reproducibility. | USP <791> mandates pH measurement procedures. Method robustness (ICH Q14) depends on pH control. |

| Forced Degradation Reagents (0.1N HCl/NaOH, Hâ‚‚Oâ‚‚) | To generate degradation products for specificity validation of the stability-indicating method. | Directly required by ICH Q3A/B and ICH Q1A/B for stability studies. |

| HPLC Columns from Multiple Batches | To assess method reproducibility across column batches during robustness testing. | ICH Q14 and USP <621> emphasize column variability as a critical method parameter. |

| Residual Solvent/Class 1 Impurity Standards | For potential verification that method does not co-elute with highly toxic impurities (e.g., genotoxic). | Linked to ICH Q3C (Residual Solvents) and ICH M7 (Mutagenic Impurities) assessments. |

| System Suitability Test Mixtures (e.g., USP Tailing Mixture) | To verify chromatographic system performance before analysis, ensuring data validity. | Mandatory requirement per USP <621> and integral to ICH Q6A. |

| 5-Methyl-5-propyl-1,3-dioxan-2-one | 5-Methyl-5-propyl-1,3-dioxan-2-one, CAS:7148-50-7, MF:C8H14O3, MW:158.19 g/mol | Chemical Reagent |

| 3,3-Bis(4-hydroxy-2,5-dimethylphenyl)isobenzofuran-1(3H)-one | 3,3-Bis(4-hydroxy-2,5-dimethylphenyl)isobenzofuran-1(3H)-one | High-purity 3,3-Bis(4-hydroxy-2,5-dimethylphenyl)isobenzofuran-1(3H)-one for research applications. For Research Use Only. Not for human or veterinary use. |

Within the broader thesis on HPLC method development for pharmaceutical impurities analysis, the Analytical Target Profile (ATP) serves as the foundational strategic document. It defines the required performance characteristics of an analytical procedure before development begins, ensuring the method is fit-for-purpose. This shifts the paradigm from simply "validating a developed method" to "designing to meet predefined criteria," aligning with Quality by Design (QbD) principles.

Core Components of an ATP for Impurity Methods

An ATP is a prospective, risk-informed summary of the quality attributes an analytical method must possess. For impurity methods, key components include:

- Analyte & Matrix: Identification of specific impurities (process-related, degradants) and the drug substance/product matrix.

- Analytical Measurement: The property to be measured (e.g., concentration, % area).

- Required Performance Standards: Quantitative targets for attributes such as:

- Accuracy and Precision (Repeatability, Intermediate Precision)

- Specificity/Selectivity (Resolution from main peak and other impurities)

- Detection Limit (LOD) and Quantitation Limit (LOQ)

- Linearity and Range

- Robustness (acceptable ranges for critical method parameters)

Quantitative ATP Criteria Table for Impurity Methods

The following table summarizes typical, science-based targets for a stability-indicating impurity method, as derived from current regulatory guidelines (ICH Q2(R2), Q14) and industry practice.

Table 1: Example Quantitative ATP Criteria for a HPLC Impurity Method

| ATP Attribute | Target Performance Criteria | Justification / Regulatory Link |

|---|---|---|

| Objective | Quantify specified impurities and report unspecified impurities in drug product. | ICH Q3B(R2) |

| Selectivity | Resolution (Rs) ≥ 2.0 between all impurity peaks and from the API peak. | Ensures baseline separation for accurate integration. |

| LOD | ≤ Reporting Threshold (e.g., 0.05% for drug product). | ICH Q3B: Impurities below the reporting threshold are not required to be reported. |

| LOQ | ≤ Reporting Threshold with precision (RSD ≤ 10%) and accuracy (80-120%). | Must reliably quantify at the reporting threshold. |

| Linearity & Range | From LOQ to at least 120% of specification limit (e.g., 0.05% to 0.6%). R² ≥ 0.990. | Covers from reporting threshold to above the qualification threshold. |

| Accuracy (at LOQ, 100%) | Mean recovery 80-120% (LOQ), 90-110% (other levels). | Confirms method's trueness across the range. |

| Precision (Repeatability) | RSD ≤ 5.0% at specification level (e.g., 0.5%). | ICH Q2(R2): For impurity levels ~0.5%, an RSD of 5-10% is generally acceptable. |

| Intermediate Precision | RSD ≤ 7.0% (incorporates inter-day, analyst, instrument variability). | Demonstrates method reliability under expected lab variations. |

| Robustness | Method tolerates ± 0.1 pH in buffer, ± 2°C column temp, ± 5% organic modifier variation without failure. | Identifies critical method parameters for control. |

Experimental Protocol: Establishing Method Selectivity (Specificity)

This protocol is a critical experiment to confirm the ATP requirement for selectivity.

Protocol 1: Forced Degradation Study for Selectivity Demonstration

Objective: To demonstrate the method's ability to separate and resolve degradation products from the Active Pharmaceutical Ingredient (API) and from each other.

Materials & Reagents:

- API and Drug Product samples.

- Stress Agents: 0.1M HCl, 0.1M NaOH, 3% Hâ‚‚Oâ‚‚, solid for thermal stress, light chamber.

- HPLC System: With UV/DAD or MS-compatible detector.

- Chromatographic Column: As per the method under development (e.g., C18, 150 x 4.6 mm, 2.7 µm).

Procedure:

- Sample Preparation: Expose separate aliquots of API and drug product to the following conditions:

- Acidic Hydrolysis: Treat with 0.1M HCl at 60°C for 1-8 hours. Neutralize.

- Basic Hydrolysis: Treat with 0.1M NaOH at 60°C for 1-8 hours. Neutralize.

- Oxidation: Treat with 3% Hâ‚‚Oâ‚‚ at room temperature for 1-24 hours.

- Thermal: Heat solid at 105°C for up to 1 week.

- Photolytic: Expose to ~1.2 million lux hours of visible and UV light (ICH Q1B).

- Analysis: Inject stressed samples, unstressed controls, and blank solutions using the draft HPLC method.

- Data Analysis:

- Assess chromatograms for peak purity of the API peak using a Diode Array Detector (DAD).

- Calculate resolution (Rs) between the API peak and the nearest degradant peak, and between any degradant peaks expected to be reported.

- Ensure all degradant peaks are resolved (Rs ≥ 2.0) and that the API peak is pure.

Protocol: Determination of LOD and LOQ

This protocol validates the quantitative limits defined in the ATP.

Protocol 2: Establishing LOD and LOQ Based on Signal-to-Noise

Objective: To experimentally determine the Limit of Detection (LOD) and Limit of Quantitation (LOQ) for a specified impurity.

Procedure:

- Preparation: Prepare a diluted impurity stock solution at a concentration near the expected LOD/LOQ (e.g., at the reporting threshold).

- Chromatography: Inject this solution at least six times.

- Signal-to-Noise Calculation: For each injection, measure the height of the impurity peak (H) and the peak-to-peak noise (N) in a blank chromatogram over a region adjacent to the impurity retention time.

- Calculate Signal-to-Noise (S/N) = H / N.

- LOD & LOQ Determination:

- LOD: The concentration at which the average S/N is approximately 3:1.

- LOQ: The concentration at which the average S/N is approximately 10:1.

- LOQ Verification: At the determined LOQ concentration, perform six independent preparations and injections. Verify the method precision (RSD ≤ 10%) and accuracy (mean recovery 80-120%).

Visualizing the ATP-Driven Method Development Workflow

Title: QbD Workflow for Impurity Method Development Driven by ATP

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents & Materials for Impurity Method Development

| Item | Function / Application |

|---|---|

| High-Purity Reference Standards (API & Impurities) | Essential for accurate identification, method development, and establishing system suitability criteria (e.g., resolution). |

| MS-Grade Water & Organic Solvents (Acetonitrile, Methanol) | Minimizes baseline noise and ghost peaks in sensitive gradient HPLC methods, crucial for low-level impurity detection. |

| Volatile Buffering Agents (Ammonium formate, ammonium acetate) | Provides pH control for separation selectivity; essential for mass spectrometry (LC-MS) compatibility during impurity identification. |

| Forced Degradation Stress Agents (HCl, NaOH, Hâ‚‚Oâ‚‚) | Used in specificity protocols to generate degradants and demonstrate method stability-indicating capability. |

| HPLC Columns with Different Selectivities (C18, C8, Phenyl, HILIC) | Screening columns is critical to achieve the ATP-defined selectivity for complex impurity profiles. |

| Diode Array Detector (DAD) or Mass Spectrometer (MS) | DAD ensures peak purity; MS is indispensable for unambiguous identification of unknown impurities. |

| Quality Control (QC) Samples (at LOQ, Specification Level) | Used throughout method development and validation to continually assess method performance against ATP targets. |

| Sodium 3-(cyclohexylamino)propane-1-sulfonate | Sodium 3-(cyclohexylamino)propane-1-sulfonate, CAS:105140-23-6, MF:C9H18NNaO3S, MW:243.3 g/mol |

| 1-Benzofuran-6-amine | 1-Benzofuran-6-amine|High-Purity Research Chemical |

The HPLC Method Development Workflow: A Step-by-Step Guide from Scouting to Final Conditions

In the systematic development of a robust HPLC method for pharmaceutical impurities analysis, the initial characterization of the target molecule and its known impurities is paramount. This first step involves the assessment of fundamental physicochemical properties: acid dissociation constant (pKa), partition coefficient (LogP), and ultraviolet (UV) absorption spectra. These parameters directly inform critical HPLC decisions, including mobile phase pH, column chemistry, and detector wavelength selection. A thorough scouting phase, framed within a research thesis on method development, establishes a scientific foundation, prevents method failures, and accelerates the path to a validated analytical procedure.

Key Physicochemical Properties & Their Impact on HPLC Method Development

| Property | Definition | Analytical Technique(s) | Direct Implication for HPLC Method Development |

|---|---|---|---|

| pKa | The pH at which a molecule is 50% ionized and 50% non-ionized. | Potentiometric titration, UV-Vis spectrophotometric titration, Capillary Electrophoresis. | Determines optimal mobile phase pH to control ionization, thereby affecting retention, peak shape, and selectivity. A pH ±1.5 units from the pKa is typically chosen for stability. |

| LogP (Log D) | Log10 of the partition coefficient of the neutral species between octanol and water (P). Log D describes the distribution at a specific pH. | Shake-flask method, Reversed-Phase HPLC (RP-HPLC) estimation, Computational prediction. | Predicts retention time on reversed-phase columns. Higher LogP indicates stronger hydrophobic interaction with the C18 stationary phase and longer retention. |

| UV Spectra | The pattern of ultraviolet light absorption as a function of wavelength. | UV-Vis Spectrophotometry (190-400 nm). | Identifies optimal detection wavelengths for maximum sensitivity, enables wavelength switching for impurity profiling, and confirms compound identity. |

Detailed Experimental Protocols

Protocol 1: Spectrophotometric Determination of pKa

Objective: To determine the pKa of an ionizable analyte using pH-dependent UV spectral shifts. Principle: The absorbance of a chromophore near the ionization site changes with its protonation state. Monitoring absorbance at a specific wavelength across a pH range allows pKa calculation.

Materials & Reagents:

- Analyte stock solution in a water-miscible organic solvent (e.g., methanol, acetonitrile).

- Britton-Robinson universal buffer series (pH 2-12) or similar.

- UV-transparent cuvettes (quartz, 1 cm path length).

- UV-Vis spectrophotometer with temperature control.

- pH meter, accurately calibrated.

Procedure:

- Prepare a series of buffer solutions covering a broad pH range (e.g., 2, 3, 4, ..., 11) with constant ionic strength.

- For each buffer, prepare a sample solution by diluting the analyte stock to a final concentration that yields an absorbance between 0.5 and 1.0 AU. Ensure the final organic solvent content is minimal (<5% v/v) to avoid affecting pH.

- Measure the pH of each solution accurately immediately before analysis.

- Record the UV spectrum (e.g., 220-350 nm) for each pH solution.

- Identify an isosbestic point (wavelength where absorbance is independent of pH) and a wavelength where the absorbance change is maximal.

- Plot absorbance at the analytical wavelength versus pH. Fit the data to the Henderson-Hasselbalch equation using nonlinear regression software to calculate the pKa.

Protocol 2: Estimation of LogP via Reversed-Phase HPLC

Objective: To estimate the LogP of an analyte using a calibrated relationship with HPLC retention time. Principle: The logarithm of the capacity factor (log k) from a reversed-phase HPLC system correlates with LogP. A calibration curve is constructed using compounds with known LogP values.

Materials & Reagents:

- HPLC system with UV detector.

- C18 column (e.g., 150 mm x 4.6 mm, 5 µm).

- Mobile Phase: Methanol/water or acetonitrile/water (isocratic, e.g., 70:30 v/v).

- Set of standard compounds with known LogP (e.g., toluene, nitrobenzene, acetophenone, anisole).

- Test analyte.

Procedure:

- Establish an isocratic mobile phase composition that provides reasonable retention (1 < k < 10) for the standard mix.

- Inject each standard compound and the analyte. Record the retention time (tR). Calculate the capacity factor: k = (tR - t0) / t0, where t0 is the column void time determined using an unretained marker (e.g., uracil).

- Plot the known LogP values of the standards against their measured log k.

- Perform linear regression to obtain the calibration equation: LogP = a * log k + b.

- Calculate the LogP of the test analyte by substituting its log k into the calibration equation.

Protocol 3: Acquisition of UV Spectra for HPLC Wavelength Selection

Objective: To obtain the UV absorption spectrum of the primary analyte and its known impurities for optimal HPLC detection setup. Principle: Full spectral scanning identifies λ_max (wavelength of maximum absorption) and suitable secondary wavelengths for method development.

Materials & Reagents:

- UV-Vis spectrophotometer with scanning capability.

- Quartz cuvettes.

- Purified analyte and impurity standards.

- Diluent: Mobile phase intended for HPLC or a transparent solvent (e.g., methanol, water).

Procedure:

- Prepare individual solutions of the main drug substance and each available impurity at a concentration relevant for analysis (e.g., 10-50 µg/mL).

- Using the diluent as a blank, scan each solution from 190 nm to 400 nm.

- Identify the primary λ_max for each compound. Note any significant secondary absorption bands.

- For the main analyte, determine a wavelength that provides strong absorption (often λ_max) for high sensitivity in assay methods.

- For impurity methods, evaluate spectra to select a wavelength that offers a balanced response for all impurities, or program a wavelength switching method to optimize sensitivity for each specific impurity class.

Visualized Workflows

Diagram Title: Spectrophotometric pKa Determination Workflow

Diagram Title: From Molecule Data to HPLC Scouting Parameters

The Scientist's Toolkit: Key Reagents & Materials

| Item | Function in Assessment & Scouting |

|---|---|

| Britton-Robinson Buffer | A universal buffer system providing a stable pH gradient from 2 to 12 for pKa titrations, minimizing ionic strength variations. |

| LC-MS Grade Water & Solvents | High-purity solvents (water, methanol, acetonitrile) prevent UV interference and baseline noise during spectral analysis and LogP estimation. |

| Certified pH Calibration Standards | Essential for accurate pH meter calibration before pKa measurements, ensuring data reliability. |

| LogP Standard Kit | A set of compounds with precisely known LogP values (e.g., from US Pharmacopeia) for creating a reliable HPLC-based LogP estimation calibration curve. |

| Quartz Cuvettes (1 cm) | Provide UV transparency down to 190 nm, required for accurate full-spectrum acquisition without signal distortion. |

| Uracil or Sodium Nitrate | Unretained markers used to determine the column void time (t0) in HPLC, which is critical for calculating capacity factors (k) for LogP estimation. |

| C18 HPLC Column (150 x 4.6 mm, 5µm) | A standard, well-characterized column used for the initial LogP estimation and subsequent method scouting runs. |

| Chemical Structure Drawing Software | Used to predict ionization sites and approximate chromophores, supporting the interpretation of experimental pKa and UV data. |

| 3-Chloro-4-fluoro-5-nitrobenzotrifluoride | 3-Chloro-4-fluoro-5-nitrobenzotrifluoride, CAS:101646-02-0, MF:C7H2ClF4NO2, MW:243.54 g/mol |

| 4-Benzyloxy-3-nitroacetophenone | 4-Benzyloxy-3-nitroacetophenone, CAS:14347-05-8, MF:C15H13NO4, MW:271.27 g/mol |

Within the comprehensive framework of HPLC method development for pharmaceutical impurities analysis, selecting the appropriate stationary phase is the pivotal step that dictates selectivity, sensitivity, and robustness. Reversed-phase (RP) C18, Hydrophilic Interaction Chromatography (HILIC), and charged surface hybrid (CSH) phases represent three fundamental paradigms with orthogonal selectivity. This application note provides a systematic comparison and detailed protocols to guide the scientist in making this critical choice based on analyte physicochemical properties.

Comparative Data: Stationary Phase Selection Guide

The selection is primarily driven by the relative hydrophobicity and ionization state of the target analytes and impurities.

Table 1: Stationary Phase Selection Criteria Based on Analyte Properties

| Analyte Property | Recommended Phase | Key Separation Mechanism | Typical Eluent |

|---|---|---|---|

| Hydrophobic, Non-ionic | C18 | Hydrophobic partitioning | Acetonitrile/Water or Methanol/Water |

| Moderate Polarity, Ionizable | C18 (with pH control) | Hydrophobic + ion suppression/pairing | Buffered ACN/Water (pH 2.0-3.5 or ~7.0) |

| Polar, Hydrophilic, Ionizable | Charged Surface (CSH) | Hydrophobic + electrostatic interactions | Buffered ACN/Water (pH 3-7) |

| Very Polar, Hydrophilic | HILIC | Partitioning + hydrogen bonding + electrostatic interactions | ACN/Buffered Water (High Organic, >60% ACN) |

| Polar Metabolites, Sugars, Bases | HILIC or CSH | Multi-mode retention | ACN/Ammonium formate or acetate buffer |

Table 2: Performance Characteristics for Impurity Profiling

| Parameter | C18 | HILIC | Charged Surface (CSH) |

|---|---|---|---|

| Retention of Polar Impurities | Weak, often requires derivatization or ion-pairing | Excellent | Good to Excellent |

| Peak Shape for Bases | Poor at neutral pH, tailing | Good with proper buffer | Excellent, even at low ionic strength |

| Method Development Speed | Fast (mature knowledge) | Moderate (sensitive to %water, buffer) | Fast (forgave to buffer concentration changes) |

| MS-Compatibility | Excellent | Excellent (high organic) | Excellent |

| Equilibration Time | Moderate | Long (hydration state critical) | Moderate to Fast |

Experimental Protocols

Protocol 3.1: Initial Scouting Gradient for Phase Selection

Objective: To rapidly assess the retention and selectivity of a mixture of API and its known impurities across different stationary phases.

Research Reagent Solutions:

- Mobile Phase A: 20 mM Ammonium Formate, pH 3.0 (aqueous). Function: Buffers pH to suppress ionization of acids/bases, MS-compatible.

- Mobile Phase B: Acetonitrile (LC-MS Grade). Function: Organic modifier for gradient elution.

- Diluent: 50:50 (v/v) mixture of Mobile Phase A and B. Function: Matches initial mobile phase conditions to minimize injection effects.

- Analyte Stock Solution: Prepare at ~1 mg/mL of API and each impurity in diluent.

Procedure:

- Equip identical HPLC systems with columns of similar dimensions (e.g., 100 x 4.6 mm, 2.7 µm) packed with C18, HILIC (silica or amide), and CSH (C18 with embedded charged groups).

- Set column oven to 30°C. UV detection at 220 nm (or API-specific λmax).

- For C18 & CSH: Use gradient from 5% B to 95% B over 15 min. Hold for 2 min.

- For HILIC: Use gradient from 95% B to 50% B over 15 min. Hold for 2 min. Note: Ensure column is equilibrated in high organic (>10 column volumes) before first run.

- Inject 10 µL of the spiked analyte solution.

- Compare chromatograms. Evaluate: retention of earliest eluting polar impurity, peak symmetry of basic compounds, and overall spread of peaks across the gradient.

Protocol 3.2: Optimizing pH and Buffer on a Charged Surface Hybrid (CSH) Column

Objective: To fine-tune selectivity for a challenging separation of co-eluting acidic and basic impurities.

Research Reagent Solutions:

- Buffer Solutions (10 mM): Prepare Ammonium Formate at pH 2.7, 3.5, 5.0, and 6.8. Filter through 0.22 µm nylon membrane.

- Analyte Solution: API spiked with impurity mix in diluent (75:25 B:A for CSH initial conditions).

Procedure:

- Install CSH C18 column (e.g., 150 x 3.0 mm, 1.7 µm).

- Set a shallow gradient appropriate for the analyte's mid-polarity (e.g., 25% B to 65% B over 20 min). Use a low flow rate (e.g., 0.4 mL/min) for UHPLC.

- Perform four sequential injections, changing only the aqueous component (Mobile Phase A) to each of the four pH buffers.

- Plot retention time vs. pH for each critical pair. Identify the pH that maximizes resolution (ΔRT).

- If needed, perform a follow-up scouting run varying buffer concentration (e.g., 5 mM, 10 mM, 20 mM) at the optimal pH to further modulate electrostatic interactions.

Visualization of Method Development Logic

Decision Tree for Stationary Phase Selection

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Stationary Phase Evaluation

| Reagent/Material | Function in Method Development |

|---|---|

| C18 Column (e.g., BEH C18) | Benchmark reversed-phase column; assesses hydrophobic retention and general method feasibility. |

| HILIC Column (e.g., BEH Amide) | Evaluates retention of very polar impurities; provides orthogonal selectivity to RP. |

| CSH Column (e.g., CSH C18) | Solves peak shape issues for basic compounds; offers mixed-mode retention. |

| Ammonium Formate (LC-MS Grade) | Universal volatile buffer for pH control (pH ~2.7-3.5, 6.5-7.0) and ion-pairing in MS-compatible methods. |

| Trifluoroacetic Acid (TFA) | Provides strong ion-pairing and pH control (~pH 2) for UV methods; improves peak shape of proteins/bases. |

| Ammonium Hydroxide (LC-MS Grade) | Adjusts mobile phase to high pH for separation of acidic compounds or for alternative selectivity. |

| Acetonitrile (LC-MS Grade) | Primary organic modifier for gradients in RP, CSH, and HILIC. |

| 0.22 µm Nylon & PTFE Filters | Filtration of all aqueous buffers (nylon) and organic solvents (PTFE) to prevent column clogging. |

| 4-Benzyloxybromobenzene | 4-Benzyloxybromobenzene, CAS:6793-92-6, MF:C13H11BrO, MW:263.13 g/mol |

| D(+)-10-Camphorsulfonyl chloride | D(+)-10-Camphorsulfonyl chloride, CAS:21286-54-4, MF:C10H15ClO3S, MW:250.74 g/mol |

Within the comprehensive framework of a thesis on HPLC method development for pharmaceutical impurities analysis, mobile phase optimization is the critical step that determines selectivity, resolution, and peak shape. This application note details the systematic approach to optimizing the aqueous component (pH and buffer) and the organic modifier to achieve robust separation of drug substances from their potentially genotoxic, degradation, or synthesis-related impurities. The principles outlined are foundational for developing stability-indicating methods as per ICH Q3B(R2) guidelines.

Core Principles and Key Parameters

Influence of pH

The pH of the aqueous mobile phase is the primary lever for controlling the ionization state of ionizable analytes (acids, bases, zwitterions). For reversed-phase HPLC (RP-HPLC), which is the workhorse of impurity profiling, manipulating pH alters analyte hydrophobicity and thus retention.

- Acidic Analytes (pKa < 7): Lower pH (< pKa - 2) suppresses ionization (protonated, neutral form), increasing retention. Higher pH (> pKa + 2) promotes ionization (deprotonated, charged form), drastically decreasing retention.

- Basic Analytes (pKa > 7): Lower pH (< pKa - 2) promotes ionization (protonated, charged form), decreasing retention. Higher pH (> pKa + 2) suppresses ionization (deprotonated, neutral form), increasing retention.

Optimal pH Window: Typically 2.0–3.0 for basic compounds using acidic buffers to suppress silanol activity and improve peak shape, and 4.5–6.0 for acidic compounds to control ionization. Most separations are performed at pH 2.5–3.0 (phosphate or formate) or pH 4.5–5.0 (acetate).

Buffer Selection and Concentration

Buffers maintain a stable pH, critical for reproducible retention times. Key selection criteria include:

- UV Cut-Off: Must be transparent at the detection wavelength.

- Buffer Capacity: Sufficient to withstand sample injection (pKa ± 1.0 is optimal).

- HPLC-MS Compatibility: Volatile buffers (ammonium formate, ammonium acetate) are mandatory.

- Column Compatibility: Avoid phosphate buffers with silica-based columns above pH 7.5–8.0.

Organic Modifier Selection

The organic solvent (modifier) strength and type control elution power and selectivity.

- Strength: Acetonitrile (ACN) is stronger than methanol (MeOH) in RP-HPLC (e.g., 60% MeOH ≈ 45% ACN for similar retention).

- Selectivity: Changing from MeOH to ACN (or adding tetrahydrofuran) can alter selectivity due to different hydrogen-bonding, dipole-dipole, and dispersion interactions. MeOH is more protic and can better mask residual silanols.

Table 1: Common HPLC Buffers for Impurity Analysis

| Buffer Salt | Useful pH Range | pKa at 25°C | Typical Concentration | UV Cut-off (nm) | Primary Use Case |

|---|---|---|---|---|---|

| Ammonium Formate | 2.8–4.8 | 3.75 | 5–20 mM | 210 | LC-MS methods, acidic to mid pH |

| Ammonium Acetate | 3.8–5.8 | 4.75 | 5–20 mM | 210 | LC-MS methods, mid pH |

| Potassium Phosphate | 1.1–3.1 / 6.2–8.2 | 2.1, 7.2, 12.3 | 10–50 mM | <200 (Low UV) | High UV sensitivity, stability studies |

| Trifluoroacetic Acid | 1.5–2.5 | ~0.5 | 0.05–0.1% (v/v) | 210 (strong absorbance) | Ion-pairing for bases, improves peak shape |

| Formic Acid | 1.8–3.8 | 3.75 | 0.1–0.5% (v/v) | 210 | LC-MS methods, acidic pH |

Table 2: Effect of pH on Retention Time (k) of Model Compounds*

| Compound Type (pKa) | pH 2.0 | pH 3.0 | pH 4.5 | pH 6.0 | pH 7.5 |

|---|---|---|---|---|---|

| Acidic (4.2) | k=2.1 | k=1.9 | k=1.2 | k=0.8 | k=0.5 |

| Basic (8.7) | k=1.0 | k=1.8 | k=4.5 | k=7.2 | k=9.8 |

| Neutral | k=5.5 | k=5.5 | k=5.4 | k=5.5 | k=5.5 |

*Conditions: C18 column, 30% ACN, 25 mM buffer. Data is illustrative.

Table 3: Organic Modifier Comparison

| Modifier | Polarity Index (P') | Viscosity (cP) | UV Cut-off (nm) | Key Selectivity Traits |

|---|---|---|---|---|

| Acetonitrile | 5.8 | 0.34 | 190 | Strong eluent, low viscosity, good UV transparency. |

| Methanol | 5.1 | 0.55 | 205 | Weaker eluent, can improve peak shape for basic compounds. |

| Tetrahydrofuran | 4.0 | 0.46 | 212 | Unique selectivity for aromatic compounds; often used as additive (<10%). |

Experimental Protocols

Protocol 4.1: Initial pH Scouting Gradient Method

Objective: To determine the optimal pH for separation of a drug substance and its related impurities. Materials: See "Scientist's Toolkit" below. Procedure:

- Prepare mobile phase A at three different pH values: 2.5 (e.g., 0.1% Formic Acid), 4.5 (e.g., 20 mM Ammonium Acetate), and 7.0 (e.g., 20 mM Ammonium Bicarbonate). Adjust pH precisely with NaOH or HCl.

- Prepare mobile phase B as 100% acetonitrile for all three.

- Set up a generic gradient: 5% B to 95% B over 20 minutes. Column temperature: 30°C. Flow rate: 1.0 mL/min. Detection: 220-280 nm as appropriate.

- Inject the standard mixture containing the API and all available impurities on the same column using each pH condition.

- Evaluate chromatograms for overall resolution, peak shape (asymmetry factor, As), and the critical pair resolution (Rs). Select the pH providing the best overall separation.

Protocol 4.2: Buffer Strength and Organic Modifier Optimization

Objective: To fine-tune selectivity and efficiency after selecting the optimal pH. Materials: See "Scientist's Toolkit." Procedure:

- Buffer Strength Study: At the chosen pH, prepare three concentrations of the buffer (e.g., 5 mM, 20 mM, 50 mM). Run the gradient method from Protocol 4.1. Observe retention time stability and peak shape. Select the lowest concentration that provides stable retention (typically 10-20 mM).

- Organic Modifier Scouting: At the chosen pH and buffer concentration, prepare isocratic methods with three different organic modifiers: ACN, MeOH, and a mixture (e.g., 90% ACN / 10% MeOH). Adjust %B to get a main peak retention time (k) between 2 and 10.

- Inject the standard mixture under each isocratic condition. Record the elution order and resolution of the critical impurity pair.

- Fine-Tuning with Gradient Slope: Return to the best modifier system. Using a gradient, vary the slope (e.g., 1, 2, and 3% B per minute). Optimize for resolution across the entire chromatogram within a reasonable run time.

Visualization Diagrams

Title: Mobile Phase Optimization Decision Workflow

Title: Analyte Ionization & Retention vs. Mobile Phase pH

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions for Mobile Phase Optimization

| Item / Reagent | Function & Rationale |

|---|---|

| HPLC-Grade Water | Aqueous mobile phase base. Low UV absorbance and minimal particulates prevent baseline noise and column blockage. |

| HPLC-Grade Acetonitrile & Methanol | Organic modifiers. High purity ensures low UV background and avoids ghost peaks. |

| Ammonium Acetate (≥99.0%) | Volatile buffer salt for LC-MS compatible methods in the mid-pH range (3.8–5.8). |

| Ammonium Formate (≥99.0%) | Volatile buffer salt for LC-MS methods at lower pH (2.8–4.8). |

| Formic Acid (LC-MS Grade) | Used to acidify mobile phase for pH control and ion-pairing. Improves peak shape for basic compounds. |

| Trifluoroacetic Acid (HPLC Grade) | Strong ion-pairing agent and acidifier. Used at low % to dramatically improve peak shape of bases. |

| Phosphoric Acid / Potassium Phosphate | For non-MS methods requiring low UV detection (<210 nm) and high buffer capacity. |

| pH Meter with ATC & Buffer Solutions | For accurate, temperature-compensated mobile phase pH adjustment to ensure reproducibility. |

| 0.22 µm Nylon & PTFE Membrane Filters | For filtration of all aqueous buffers (nylon) and organic solvents (PTFE) to remove particulates. |

| Sonication Bath | For consistent and efficient degassing of mobile phases to prevent pump and detector issues. |

| 2-Hydroxy-4-methylpyrimidine hydrochloride | 2-Hydroxy-4-methylpyrimidine hydrochloride, CAS:5348-51-6, MF:C5H7ClN2O, MW:146.57 g/mol |

| Didesmethylsibutramine | Didesmethylsibutramine |

Within the systematic framework of HPLC method development for pharmaceutical impurities analysis, the gradient profile design is a critical determinative step. This phase follows initial scouting and column screening, focusing on the precise manipulation of the mobile phase composition over time to achieve optimal resolution between the active pharmaceutical ingredient (API) and all potential impurities—both known (specified) and unknown. A well-designed gradient is paramount for achieving the necessary peak capacity to resolve complex mixtures, ensuring accurate quantification, and meeting stringent regulatory requirements (ICH Q3A(R2), Q3B(R2)). This protocol details a systematic, data-driven approach to gradient optimization, enabling robust methods suitable for stability-indicating assays.

Core Principles and Strategy

The primary objective is to maximize the resolution (Rs ≥ 2.0 between all critical peak pairs) while minimizing the overall run time. The strategy involves a multi-stage process:

- Initial Gradient Scoping: Establishing a wide gradient window to determine the approximate elution range of all components.

- Critical Peak Pair Identification: Using software-assisted modeling to identify poorly resolved or co-eluting peaks.

- Segmented Gradient Optimization: Refining specific gradient segments to improve resolution of critical pairs without unnecessarily extending other regions.

- Robustness Verification: Testing the final gradient for its sensitivity to minor, expected variations in system parameters (e.g., flow rate, temperature, organic modifier batch).

Experimental Protocol: Gradient Optimization for Impurity Resolution

Materials and Equipment

- HPLC System: UHPLC or HPLC system with quaternary pump, autosampler (maintained at 4-10°C), column oven, and diode array detector (DAD). Capable of precise low-pressure or high-pressure mixing.

- Column: Selected stationary phase from prior screening (e.g., C18, 100 x 2.1 mm, 1.7-1.8 µm particle size).

- Mobile Phase A: Aqueous buffer (e.g., 10 mM potassium phosphate, pH 2.5, or 0.1% formic acid). Filter through 0.22 µm nylon membrane.

- Mobile Phase B: Organic solvent (e.g., Acetonitrile, HPLC grade). Filter through 0.22 µm PTFE membrane.

- Sample Solutions:

- API Solution: Target concentration (e.g., 1 mg/mL).

- Stressed API Solution: API subjected to forced degradation (acid, base, oxidative, thermal, photolytic) to generate unknown impurities.

- Impurity Spiking Solution: Mixture of all available impurity reference standards at specified levels (e.g., 0.1% relative to API).

Procedure

Step 1: Initial Wide Gradient Run

- Prepare mobile phases as described.

- Set column temperature to 35°C (±0.5°C). Set flow rate appropriate for column dimensions (e.g., 0.4 mL/min for 2.1 mm ID).

- Program a wide, linear gradient: 5% B to 95% B over 20 minutes. Hold at 5% B for 2 min, and at 95% B for 3 min for column equilibration and cleaning.

- Inject stressed API sample (e.g., 2 µL). Use DAD to acquire spectra from 200-400 nm.

- Key Data Recorded: Retention time of API, first eluting impurity, and last eluting impurity. This defines the required "gradient window."

Step 2: Generation of Critical Peak Pair Map

- Using the data from Step 1, create a blend of the stressed API and the impurity spiking solution.

- Run the same wide gradient. Integrate all peaks with a signal-to-noise (S/N) > 10.

- Input retention times into gradient modeling software (e.g., DryLab, ChromSword, or ACD Labs).

- The software will generate a resolution map, plotting calculated resolution against gradient time or steepness. Identify "critical pairs" (Rs < 1.5).

Step 3: Segmented Gradient Design & Experimental Verification

- Based on the resolution map, design a segmented gradient. The goal is to flatten the gradient slope where critical pairs elute and steepen it in regions with no peaks.

- Example: Initial hold for early eluters, shallow ramp through the critical pair region, steep ramp to elute late retainers.

- Program the new, segmented method. Ensure the total run time, including equilibration, is practical (< 25 min).

- Perform the injection in triplicate. Calculate the resolution between all adjacent peaks.

Step 4: Final Optimization and Robustness Check

- If resolution for all critical pairs is ≥ 2.0, proceed. If not, adjust the slope (∆%B/min) in the critical segment iteratively.

- To test robustness, create a minor deliberate variation (±0.05 mL/min in flow, ±2°C in temperature, ±2% absolute in starting B composition).

- Run the method with these varied conditions. Record the shift in retention time of the API and the resolution of the worst-case critical pair.

Data Analysis and Acceptance Criteria

- Primary: Resolution (Rs) between the API and its closest eluting impurity, and between all impurity-impurity pairs. Target: Rs ≥ 2.0.

- Secondary: Peak asymmetry (As) for all peaks. Target: 0.8 - 1.5.

- Tertiary: Retention time reproducibility (%RSD < 0.5% for n=3).

Table 1: Example Gradient Optimization Data for Fictitious API "Xylazine HCL"

| Gradient Design | Total Runtime (min) | Critical Pair (Imp A / API) | Resolution (Rs) | Peak Capacity* | Comment |

|---|---|---|---|---|---|

| Initial: 5-95% B in 20 min | 25 | Imp B / Imp C | 0.8 (Co-elution) | 125 | Failed; critical co-elution. |

| Optimized Segmented | 22 | API / Imp D | 2.4 | 98 | All Rs > 2.0; method viable. |

| Hold: 5% B (0-2 min) | Imp E / Imp F | 2.1 | |||

| Ramp: 5-25% B (2-10 min) | |||||

| Ramp: 25-40% B (10-15 min) | |||||

| Ramp: 40-95% B (15-17 min) | |||||

| Peak Capacity (n) = 1 + (tG / w), where tG is gradient time and w is average peak width. |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Gradient Optimization Studies

| Item | Function & Rationale |

|---|---|

| Quaternary HPLC Pump System | Enables precise, reproducible mixing of up to four solvents, essential for creating complex segmented gradients and performing solvent scouting. |

| Diode Array Detector (DAD) | Provides UV-Vis spectra for each peak, crucial for peak purity assessment and identifying co-eluting impurities with different spectral profiles. |

| Forced Degradation Samples | Stress samples (acid/base/oxidative) generate potential unknown degradants, ensuring the gradient is developed against a representative "real-world" impurity profile. |

| Gradient Modeling Software (e.g., DryLab) | Uses data from a minimal set of initial runs to predict resolution maps and optimize gradient parameters computationally, saving significant time and solvent. |

| pH Meter with Micro Electrode | Accurate preparation and verification of aqueous buffer pH is critical for reproducible retention times of ionizable analytes. |

| 0.22 µm Membrane Filters (Nylon & PTFE) | Filtration of all aqueous (nylon) and organic (PTFE) mobile phases prevents particulate column blockage and system damage. |

| 2-(6-Bromo-1H-indol-3-YL)ethanamine hydrochloride | 2-(6-Bromo-1H-indol-3-YL)ethanamine hydrochloride, CAS:108061-77-4, MF:C10H12BrClN2, MW:275.57 g/mol |

| Dibenzo[b,f][1,4]thiazepin-11(10H)-one | Dibenzo[b,f][1,4]thiazepin-11(10H)-one, CAS:3159-07-7, MF:C13H9NOS, MW:227.28 g/mol |

Visual Workflow: Gradient Optimization Process

Gradient Optimization Decision Workflow

Segmented Gradient Logic and Function

Within the systematic framework of HPLC method development for pharmaceutical impurities analysis, detector selection is a critical, multi-variable decision that directly impacts the sensitivity, specificity, and overall success of a trace analysis method. This phase determines the capability to detect, identify, and quantify low-level impurities and degradation products, which is a cornerstone of drug safety and regulatory compliance. This application note provides a detailed comparison of three primary detectors—Diode Array Detection (DAD), Fluorescence Detection (FLD), and Mass Spectrometry (MS)—and outlines specific protocols for their application in trace-level analysis within pharmaceutical research.

Detector Comparison for Trace Analysis

The selection among DAD, FLD, and MS detectors involves balancing sensitivity, selectivity, cost, and informational output. The following table summarizes their key characteristics for impurity analysis.

Table 1: Detector Comparison for Pharmaceutical Trace Analysis

| Parameter | Diode Array Detector (DAD) | Fluorescence Detector (FLD) | Mass Spectrometer (MS) |

|---|---|---|---|

| Detection Principle | UV-Vis Absorption | Emission of light after excitation | Mass-to-Charge Ratio (m/z) |

| Typical Sensitivity | Low ng (on-column) | Low pg (on-column) | High fg to pg (on-column) |

| Selectivity | Moderate (spectral matching) | Very High (dual wavelength) | Extremely High (mass accuracy) |

| Universal Detection | Yes (for chromophores) | No (requires fluorophore) | Yes (ionizable compounds) |

| Structural Info | UV-Vis spectrum, purity index | Excitation/Emission spectra | Molecular weight, fragmentation pattern |

| Compatibility with Gradient Elution | Excellent | Excellent | Requires volatile buffers & modifiers |

| Primary Use in Impurity Analysis | Quantification of known UV-active impurities | Ultra-trace analysis of native fluorescent or derivatized compounds | Unknown impurity identification, structural elucidation, quantitation |

| Key Limitation for Trace Work | Sensitivity limited for weak chromophores | Not all compounds are fluorescent | Ion suppression can affect quantitation |

| Approximate Cost | Low | Low to Moderate | High |

Experimental Protocols

Protocol 3.1: Establishing DAD Method Parameters for Impurity Profiling

Objective: To optimize DAD settings for the simultaneous detection and spectral confirmation of multiple impurities at levels ≤ 0.1% of the API.

Materials:

- HPLC system with binary pump, autosampler, and thermostatted column compartment.

- DAD detector (e.g., Agilent 1260 DAD, Waters PDA 2998).

- Analytical column: C18, 150 x 4.6 mm, 2.7 µm particle size.

- Mobile Phase A: 0.1% Formic acid in water (v/v).

- Mobile Phase B: 0.1% Formic acid in acetonitrile (v/v).

- Standard solutions: API and impurity standards at appropriate concentrations.

Procedure:

- Spectral Acquisition Setup: Program the DAD to acquire spectra from 200 nm to 400 nm. Set the bandwidth to 4 nm and the data acquisition rate to 10 Hz.

- Monitoring Wavelength: Set the primary quantification wavelength (e.g., 230 nm) based on the API's UV maxima. Set additional monitoring wavelengths (e.g., 210 nm, 254 nm) to enhance detection of impurities with different chromophores.

- Peak Purity Assessment: Inject a high-purity API standard. Use the DAD software's peak purity algorithm (e.g., threshold-based or chemometric) to establish a baseline purity profile. This profile will be used to flag potential co-eluting impurities in stressed samples.

- Sensitivity Optimization: Adjust the slit width (typically 1-4 nm) and response time (typically 0.5-2 s) to find the optimal balance between spectral resolution and signal-to-noise ratio (S/N) for trace peaks.

- Validation: Inject impurity standards at the reporting threshold (e.g., 0.05%). Ensure S/N > 10 for all specified impurities at all monitoring wavelengths.

Protocol 3.2: Developing a Highly Sensitive FLD Method for Trace Amine Impurities via Derivatization

Objective: To quantify non-fluorescent primary amine impurities at sub-ppm levels through pre-column derivatization with a fluorescent tag.

Materials:

- HPLC system with FLD (e.g., Shimadzu RF-20Axs).

- Derivatization reagent: 6-aminoquinolyl-N-hydroxysuccinimidyl carbamate (AQC), AccQ·Fluor reagent kit.

- Borate buffer (pH 8.8).

- Analytical column: C18, 150 x 3.0 mm, 1.7 µm particle size.

- Mobile Phase: AccQ·Tag eluent A (aqueous buffer) and eluent B (acetonitrile).

Procedure:

- Derivatization Reaction: Dissolve the sample containing amine impurities in borate buffer. Add the AQC reagent solution (typically 10 µL per 70 µL sample). Vortex mix immediately and heat at 55°C for 10 minutes.

- FLD Optimization: Set excitation (λex) and emission (λem) wavelengths based on the fluorophore. For AQC derivatives, use λex = 250 nm and λem = 395 nm. Fine-tune PMT voltage to achieve optimal S/N without detector saturation from the main API peak.

- Chromatographic Separation: Use a gradient elution to separate the highly fluorescent derivatives of the API and its impurities. Ensure baseline resolution of the impurity peaks of interest.

- Specificity Check: Confirm that the derivatization reagent blank does not produce interfering peaks at the retention times of the analytes.

- Calibration: Prepare and derivatize a series of impurity standards spanning the range from 0.001% to 0.5% relative to the API. Construct a calibration curve to verify linearity and sensitivity (LOQ < 0.01%).

Protocol 3.3: LC-MS Method for Unknown Impurity Identification in Forced Degradation Studies

Objective: To separate, detect, and propose structures for unknown degradation products formed under stress conditions (acid, base, oxidative, thermal).

Materials:

- UHPLC system coupled to a high-resolution mass spectrometer (e.g., Q-TOF or Orbitrap).

- Column: C18, 100 x 2.1 mm, 1.7 µm particle size.

- Mobile Phase A: 0.1% Formic acid in water.

- Mobile Phase B: 0.1% Formic acid in acetonitrile.

- Volatile buffers: Ammonium formate or acetate can be used instead of formic acid.

Procedure:

- MS Source Configuration: Operate in positive and/or negative electrospray ionization (ESI) mode. Set source parameters: desolvation temperature (e.g., 350°C), capillary voltage (e.g., 3.0 kV), and cone voltage (optimized for the API).

- Full Scan Acquisition: Acquire data in high-resolution full scan mode (e.g., m/z 100-1000) with a resolving power > 30,000 FWHM. This enables accurate mass measurement for elemental composition determination.